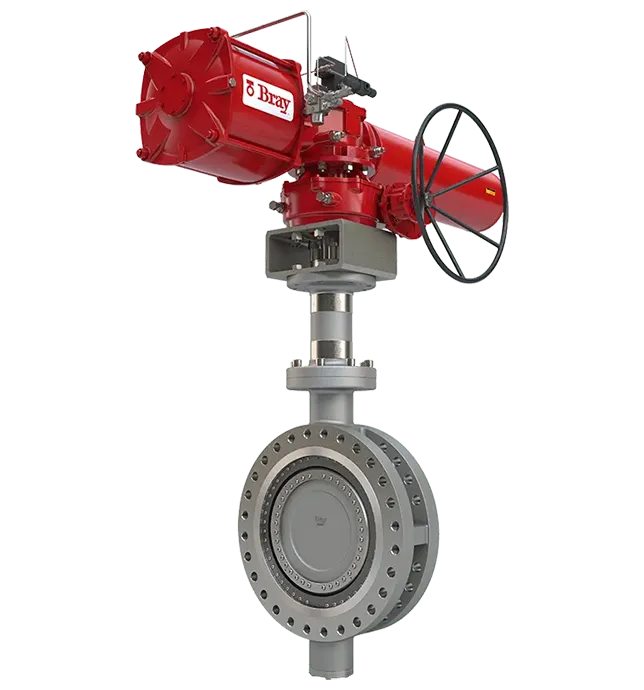

Bray Products for

Electrolyzer Plants

Electrolyzer plants produce hydrogen through electrolysis, separating water into hydrogen and oxygen molecules utilizing electricity. Green Hydrogen refers to production using a renewable energy source such as wind, solar, geothermal, or nuclear power to provide the Electrolyzer plant with electricity. Green Hydrogen is part of the global push to reduce the impact of fossil fuels on the environment, creating a more sustainable future. Bray valves and actuators can be found throughout a variety of green hydrogen production technologies including:

-

PEM Electrolyzers

-

AWE Electrolyzers

-

SOEC Electrolyzers

-

Methane pyrolysis

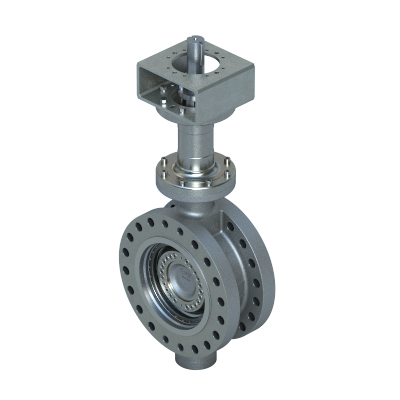

Bray Products for

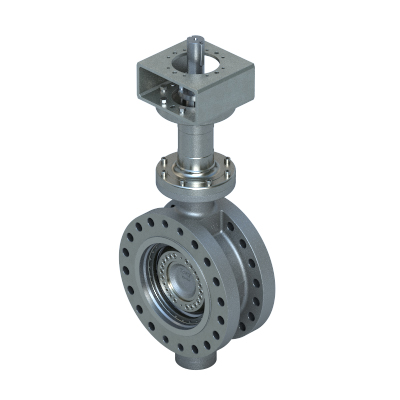

Hydrogen Compression

Hydrogen compression is an enabling technology for safe and cost-effective transport, storage, and use of hydrogen throughout the supply chain. Compression usually occurs in two stages. Low pressure pumping for hydrogen gas production to collect and concentrate hydrogen generated in Electrolyzer plants. High Pressure compression is the second stage where hydrogen is compressed to pressures up to 15,000 psi for storage and transport. High pressure hydrogen can be challenging. It is extremely flammable, requiring fire safe valve designs and requires specialty materials to prevent hydrogen embrittlement. Bray offers a full line of valves for hydrogen compression.

Bray Recommended

Hydrogen Liquification

Cryogenic liquification of hydrogen provides a lower pressure alternative to high pressure hydrogen storage. Gaseous hydrogen is liquefied by cooling it to −423°F (−253°C). Liquified hydrogen is stored in insulated tanks and one of the primary methods for distribution due to energy storage density; however, producing liquified hydrogen is an energy intensive process. Bray cryogenic valves offer reliable sealing in Hydrogen liquification applications.

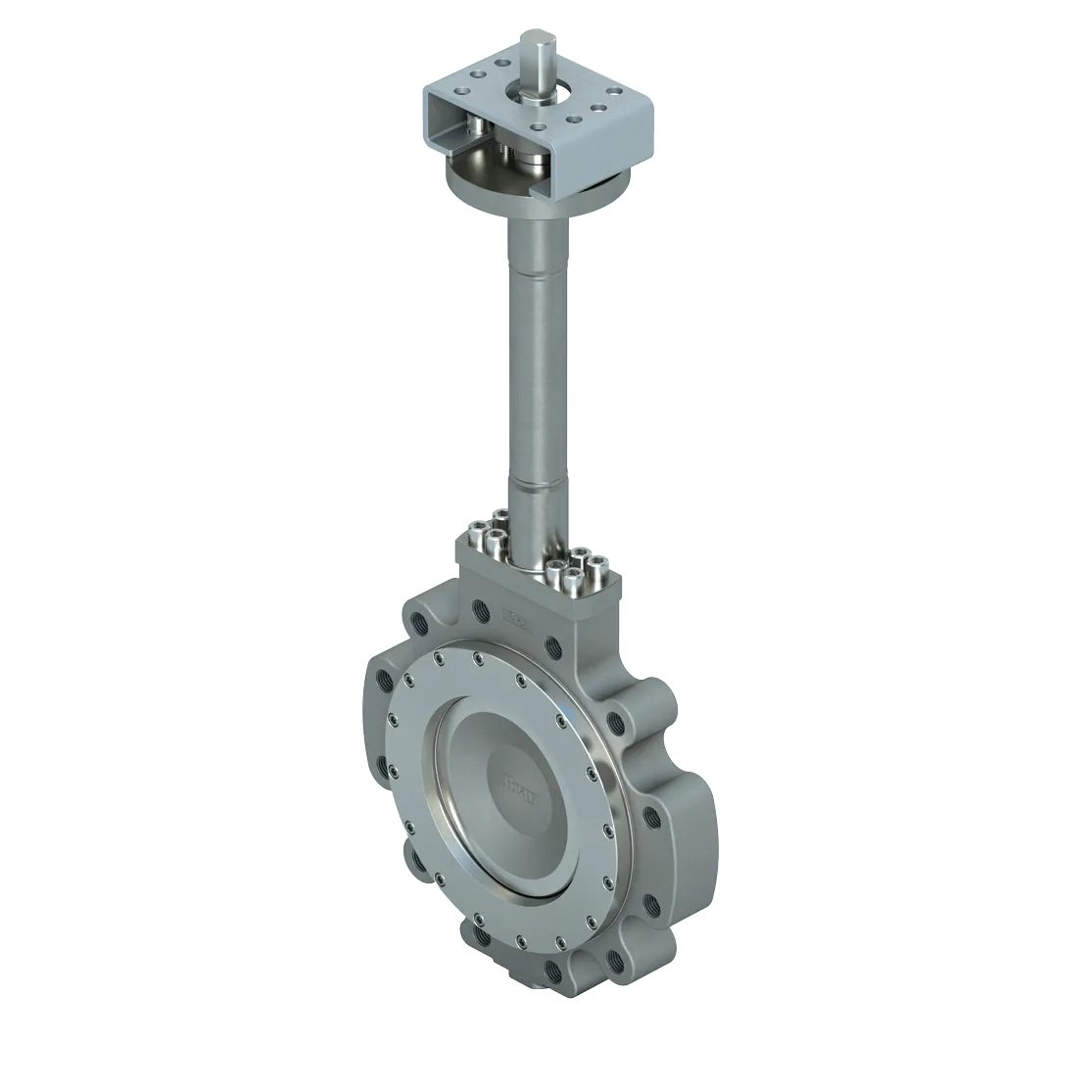

Bray's Products for

Hydrogen Storage

Physical hydrogen storage typically occurs at either very high pressures as a gas or as a liquid at cryogenic temperatures. Hydrogen gas is typically stored at 5,000 to 10,000 psi but can also be compressed and stored at pressures as high as 15,000 psi. Hydrogen storage requires special materials of construction, often made of duplex or Inconel due to hydrogen embrittlement. Bray's engineering staff and metallurgical knowledge ensures our valves are designed and engineered for long service life in hydrogen storage applications.

Bray's Products for

Hydrogen Distribution

Hydrogen is transported from production facilities to the point of use via pipelines and over the road in high pressure gaseous tube trailers or cryogenic liquid tanker trucks. Pipelines are typically deployed in regions with substantial demand (hundreds of tons per day) that is expected to remain stable for decades. Liquefaction plants, liquid tankers, and tube trailers are deployed in regions where demand is at a smaller scale or emerging. Local production utilizing electrolysis is becoming more popular to meet the demands of hydrogen while also reducing emissions and carbon footprint. Bray supports the entire hydrogen ecossystem from production to delivery with quality valves actuation and controls.

Explore More Bray Insights

Learn Even More About How Bray’s Solutions Can Impact Your Business