Bray solutions for

Reverse Osmosis

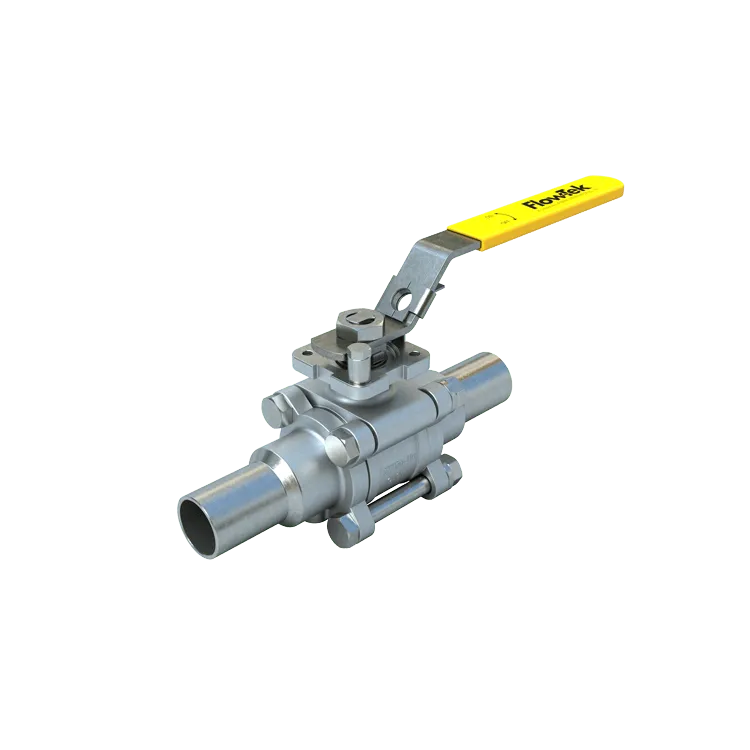

Semiconductor device manufacturing fabs typically consume millions of gallons of water daily in a variety of applications ranging from wafer fabrication processes to facilities and general utilities. The primary treatment process used to prepare high purity water in the wafer fab is reverse osmosis. Raw water is first pre-treated to remove solids, and then processed by reverse osmosis to remove organic compounds. High purity water from the Reverse osmosis system is stored for use across the wafer fab while make-up systems replenish losses. Reverse Osmosis systems are also used for wastewater reclamation in the wafer fab before discharging the water or recycling it for re-use. Bray valves, actuators and accessories are used in reverse osmosis applications for semiconductors including:

-

Process Cooling Water (PWC)

-

High Purity

-

Wafer Cleaning

-

Treatment Plants

-

Wastewater Reclamation

-

Process Cooling Water

-

Deionized Water Plants

Bray solutions for

Ultrapure Water

As lithography shrinks below 10nm the requirement for ultrapure water becomes extremely critical to the wafer fabrication process. Ultrapure water (UPW) is water that has been purified to extremely stringent specifications to establish specific composition and properties. Ultrapure water is generated by processing high purity water though a "polish system" using ultrahigh purity piping, also known as pvdf piping, to removing contaminants, minerals, microorganisms, and trace organic and nonorganic chemicals and output specification-grade water for use in the Wafer FAB. As defined by SEMI F63 for the UPW Grade used in Semiconductor manufacturing, the Bray product portfolio is designed to meet or exceed the most stringent industry requirements as required in SEMI F104 & SEMI F54. Bray Semiconductor valves are cleaned, bagged, and tagged in Bray's clean rooms, ensuring valves meet these stringent requirements. Bray valves are found in UPW Polishing solutions, storage and distribution systems including wafer cleaning, rinsing, surface conditioning, wet etch, solvent process and Chemical Mechanical Planarization.

Bray solutions for

Deionized Water

Deionization ("DI Water" or "Demineralization") simply means the removal of ions. Deionized water (DI water, DIW or de-ionized water), often synonymous with demineralized water / DM water, is water that has had almost all of its mineral ions removed, such as cations like sodium, calcium, iron, and copper, and anions such as chloride and sulfate. Deionized water is water that has had 99% of all of its mineral ions removed, resulting in a bacteria-free purified water. Deionized water is typically produced using an electrically charged ion exchange process such as an ion exchange resin tank also called a Mixed Deionize Tank or an Ion Exchange Resin tank system. It takes more than 6000 gallons of deionized water (DI) to process a single 300mm wafer in a semiconductor manufacturing fab. It takes 4-6 gallons of raw city water to generate each gallon of Deionized water.

Bray solutions for

Water Reclamation

Water Management is essential to the Semiconductor Industry. In semiconductor manufacturing, facilities rely on Ultra-Pure Water (UPW) for wafer processing. After use, the UPW water is discharged from the system as effluent. Discharge effluent typically contains hazardous chemicals and metal ions such as cyanide, pyrazole, piranha acid, peroxymonosulfuric acid and other toxic compounds. Due to the toxicity of effluent water, it must be treated and reused or discharged from the wafer fab as pure clean water. Bray valves for water reclamation, effluent treatment, recycling, and discharge are field proven.

Certified and Trusted

By thousands of companies worldwide

Our performance tested products are in compliance with a variety of global certifications and approvals, including Lloyd's Register, UL, ABS and more.

Explore More Bray Insights

Learn Even More About How Bray’s Solutions Can Impact Your Business