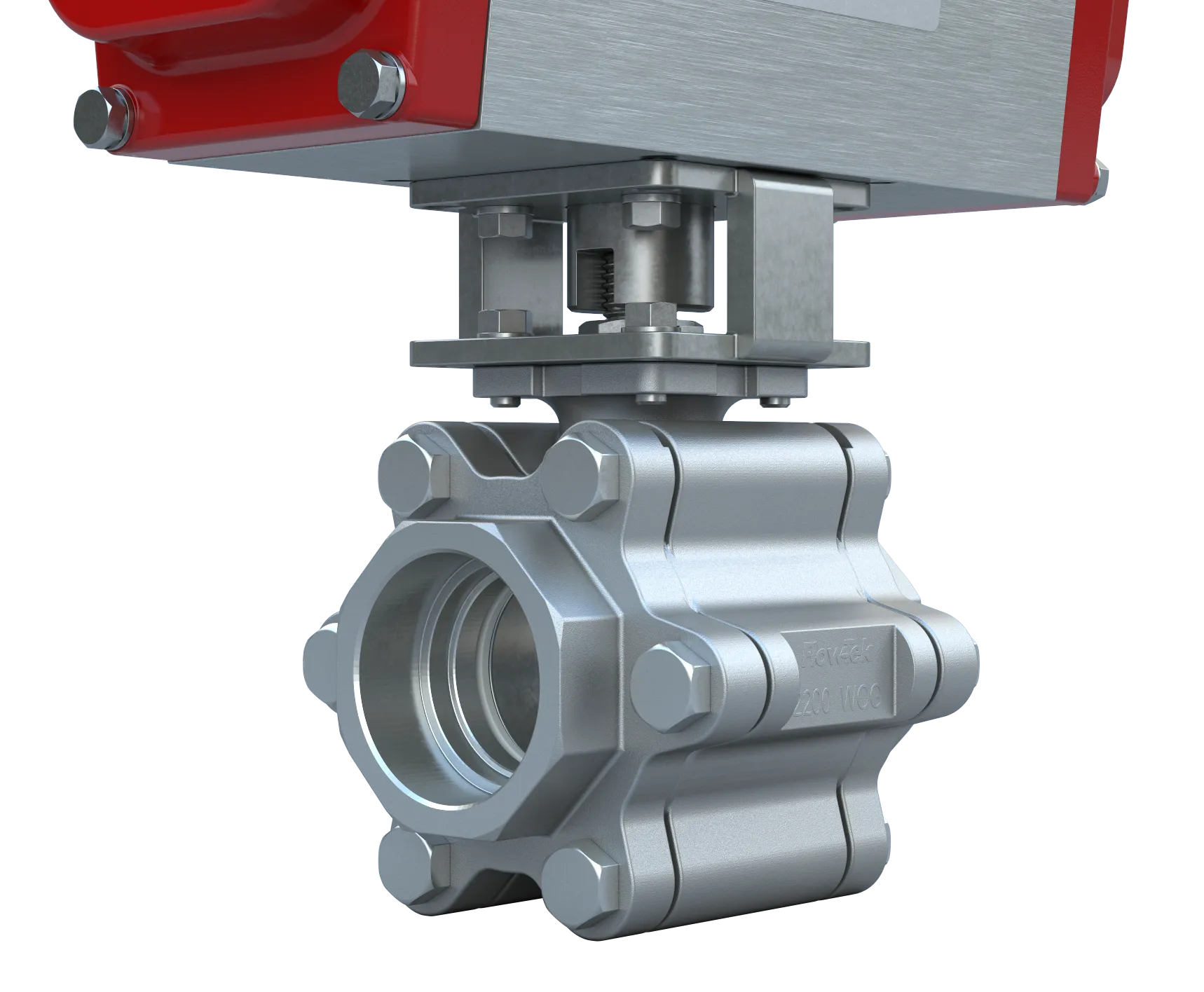

Engineered for durability and precision, this three-piece ball valve ensures dependable operation under high-pressure, high-temperature, and high-cycle conditions. Certified to API 607 and ASME B16.34 standards, it offers bubble-tight sealing with resilient and metal seating options, corrosion resistance, and maintenance-free live load stem packings for consistent performance across industrial applications.

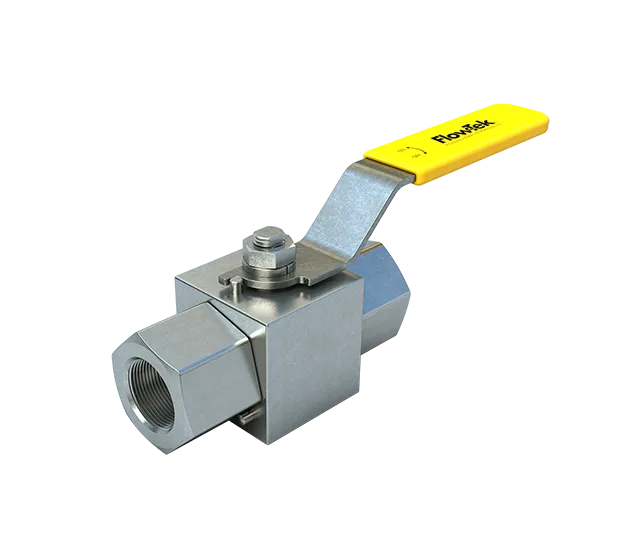

Rugged Three-Piece Ball Valves Designed for High-Performance Flow Control:

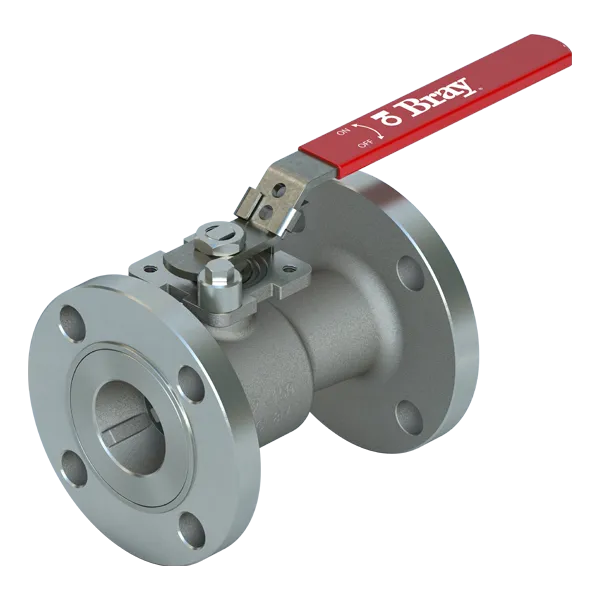

Triad Series Ball Valves are a true ASME B16.34 Class 600 ball valve (2200 WOG) engineered to deliver exceptional performance and dependable operation across a wide range of service conditions in a rugged three-piece ball valve design.

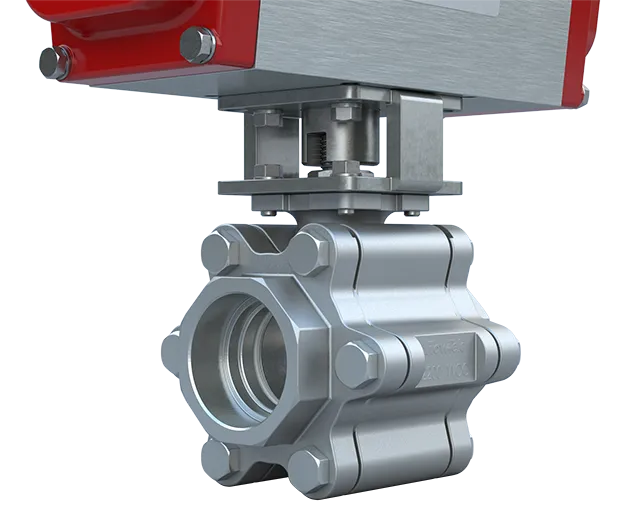

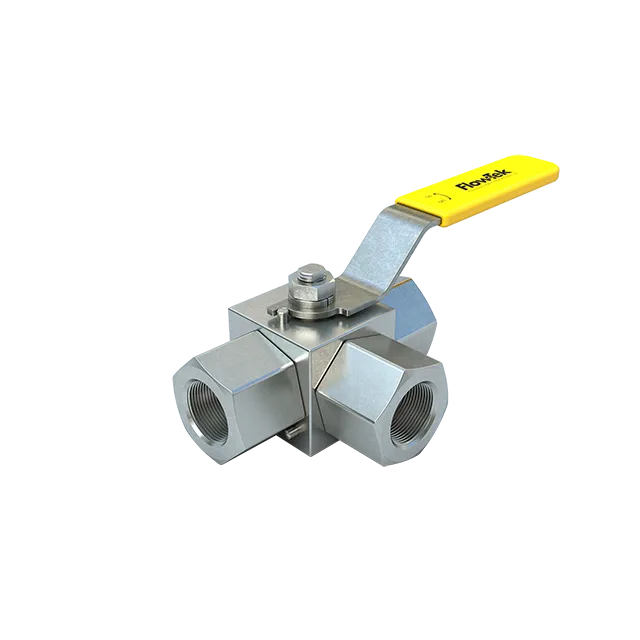

The Triad Series 3-piece ball valves feature three-piece construction with redundant main body seals and are available in full and standard port models. These rugged, high-pressure ball valves are ideal for industrial processes, high temperature, and high cycle applications. Triad features resilient seated, metal seated, and V-ball control valve trims as well as a variety of optional accessories and configurations including available anti-static protection and Fire Safe trim, Certified to API 607 4th.

Resilient seat materials include RPTFE, PEEK, TFM, Virgin PTFE, UHMWPE, Tek Fil (Carbon Graphite/TFM), and Stainless Steel Filled PTFE. All resilient seat materials ensure bi-directional, bubble-tight shutoff and positive preloading to ensure low pressure/vacuum sealing capability. Metal seated Triad valve trims feature Stellite® cobalt-chrome seat overlay ensuring superior corrosion protection, higher temperature operation and superior hardness that protects against wear.

NPS 1/4 to 2 | DN8 - 50 full port and NPS 3/4 - 2-1/2 | DN20 - 65 standard port sizes utilize self-adjusting live load stem packings featuring Belleville washers to compensate for environmental changes and wear, ensuring maintenance free operation. 3" and 4" Triad valves feature an external live load packing utilizing Belleville washers contoured to uniformly distribute the load across the packing.

With an industry leading warranty, and a reputation for reliability, Bray Triad series three-piece ball valve offer exceptional performance in a wide variety of industrial flow control applications.