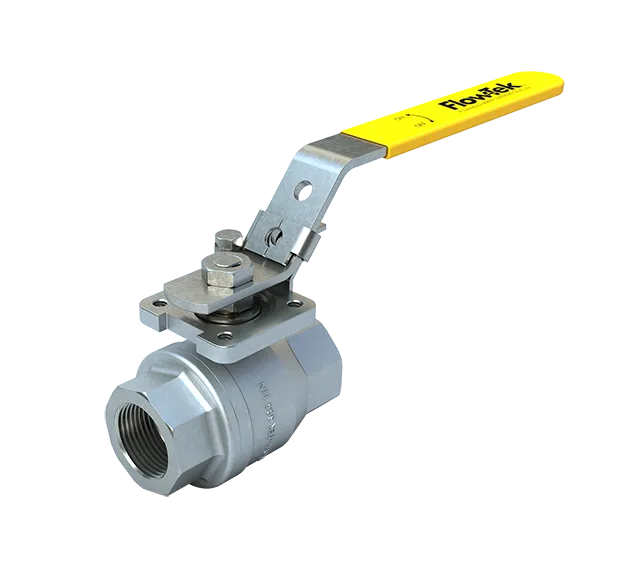

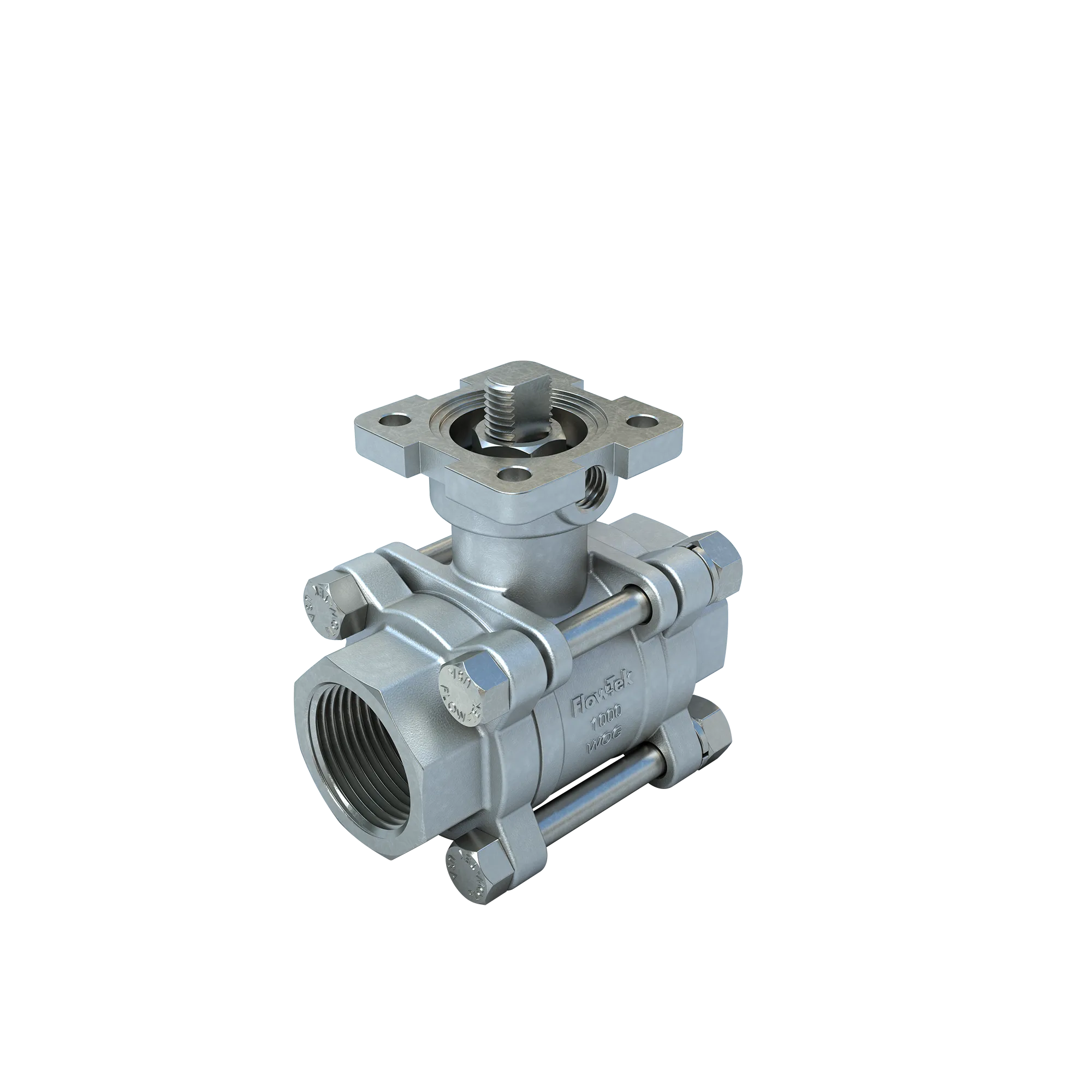

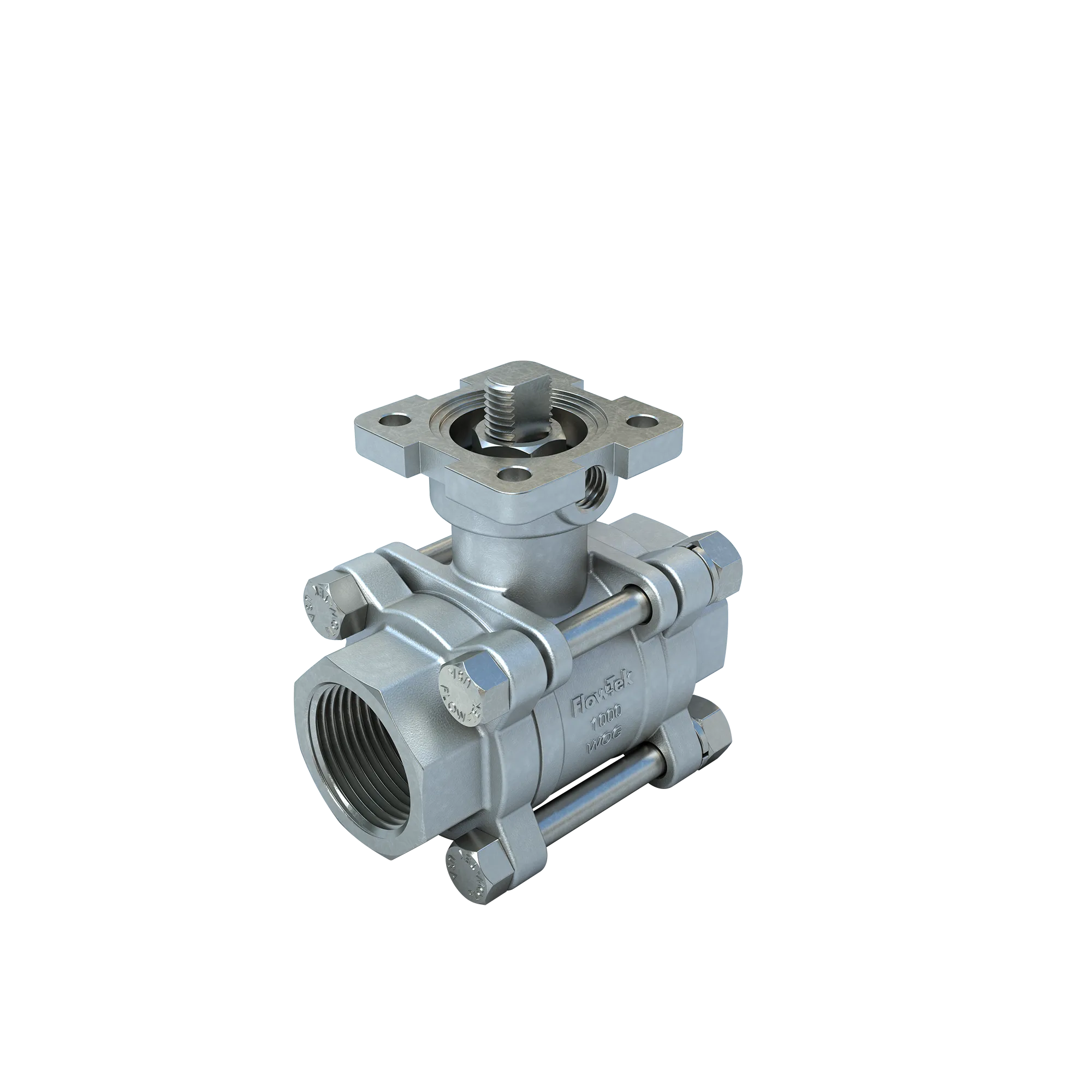

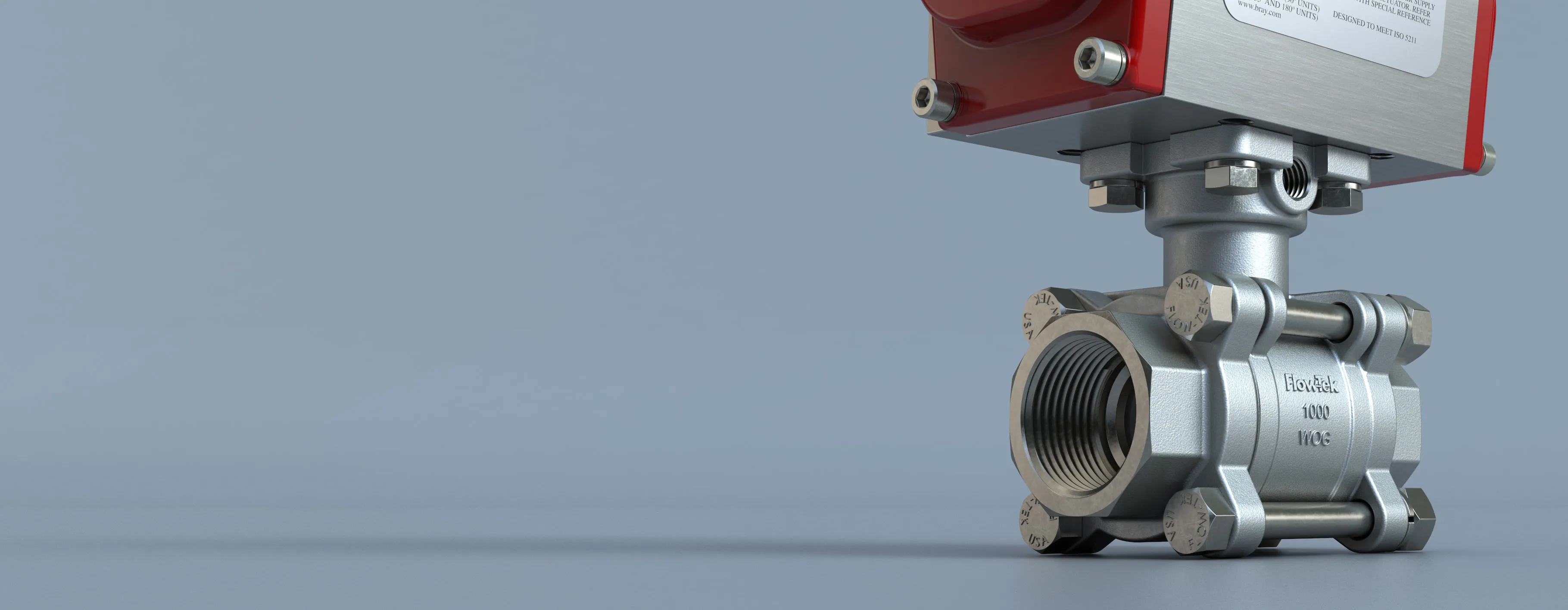

3-Piece Ball Valve

Series DM7000/DM8000

Resilient Sealing for Industrial Flow Control Applications

Innovative Fugitive Emission Control with Bray DM7000/8000 Valves

Resilient Sealing for Industrial Flow Control Applications

DM7000/8000 Series 3-piece Ball Valves feature an integrated cast direct-mounting flange designed to reduce the number of parts, the overall envelope dimensions, and hysteresis between the ball and actuator for control valve applications. The integrated mount also features an extension with a 1/8” NPT threaded side port that can be used for fugitive emissions monitoring, leak detection, fugitive emission diversion, as a Positive Pressure Seal, and as an emergency repair mechanism, enabling sealant injection through a button head check valve.

Series DM7000/DM8000 three-piece ball valves are ideal for process applications. The self-adjusting, live-load packing utilizes Belleville washers for positive preloading of the stem packing that compensates for environmental changes and wear, ensuring leak-free, bubble-tight sealing, maintenance-free operation, and long cycle life in both positive pressure and low pressure/vacuum sealing.

Resilient seat materials include RPTFE, TFM, UHMWPE, Tek Fil (Carbon Graphite/TFM), and 50/50 Stainless Steel Filled PTFE. DM7000/DM8000 is available with optional trims and configurations including V-ball control valve trims, cavity fillers, polished internals, vented balls, and other special cleaning. The flexible design of Series DM7000/DM8000 three-piece ball valves also enables in-line servicing and the ability for actuation equipment to be easily and safely removed while the valve is under full line pressure.

With an industry-leading warranty and a reputation for reliability, Bray DM7000/DM8000 series three-piece ball valves deliver exceptional performance, dependable operation, and value across a wide range of industrial flow control applications.

Series DM7000/DM8000 three-piece ball valves are ideal for process applications. The self-adjusting, live-load packing utilizes Belleville washers for positive preloading of the stem packing that compensates for environmental changes and wear, ensuring leak-free, bubble-tight sealing, maintenance-free operation, and long cycle life in both positive pressure and low pressure/vacuum sealing.

Resilient seat materials include RPTFE, TFM, UHMWPE, Tek Fil (Carbon Graphite/TFM), and 50/50 Stainless Steel Filled PTFE. DM7000/DM8000 is available with optional trims and configurations including V-ball control valve trims, cavity fillers, polished internals, vented balls, and other special cleaning. The flexible design of Series DM7000/DM8000 three-piece ball valves also enables in-line servicing and the ability for actuation equipment to be easily and safely removed while the valve is under full line pressure.

With an industry-leading warranty and a reputation for reliability, Bray DM7000/DM8000 series three-piece ball valves deliver exceptional performance, dependable operation, and value across a wide range of industrial flow control applications.

Specifications

Size Range

NPS ½ to 2 / DN 15 to 50

Body Materials

Stainless Steel CF8M, Carbon Steel WCB, Special Alloys

Temperature Range

-50°F to 550°F (-46°C to 287°C)

Stem Materials

316 Stainless Steel

Maximum Allowable Operating Pressure

1000 WOG

Seat Materials

UHMWPE, RPTFE/TFM, 50/50 SS Filled TFE, Tek-Fil®

Ball Materials

CF8M Stainless Steel

Body Style

Three Piece

Design Standard

MSS SP110

End Connections

Threaded (ASME B1.20.1 NPT), Socket Weld (ASME B16.11), Extended Socket Weld, Butt Weld (MSS SP-72, ASME B16.25), Extended Butt Weld, ASME Class 150 Flanged

Testing Standard

API 598, MSS SP72

Ports

Full Port

Downloads

Technical Bulletin

Ball Valves Actuator Selection Guide

Download

English

Technical Bulletin

Chlorine Service Ball Valves

Download

English

IOM Manual

3-Piece Full Port Ball Valves Series 7000/8000

Download

English

Product Brochure

Direct Mount 3-Piece Full Port Ball Valves Series DM7000/DM8000

Download

English

Technical Bulletin

Ball Valves Seat Materials Tek-Fil®

Download

English

Technical Bulletin

Ball Valves Selection Guide V-Control

Download

English

Our Portfolio

Looking for More Solutions?

Discover Our Range of Products Built for Your Industry's Challenges.

Explore More Bray Insights

Learn Even More About How Bray’s Solutions Can Impact Your Business

Reliable Multi-Port and Custom Valves for Pharmaceutical Manufacturing Processes

Pharmaceuticals & Biotechnology

Bray provides innovative Valve Solutions to Pharmaceutical and Biotech Companies, enhancing efficiency and agility while reducing costs in a competitive landscape.

Bray Pharma & Biotech Solutions