More Details

Features & Benefits

-

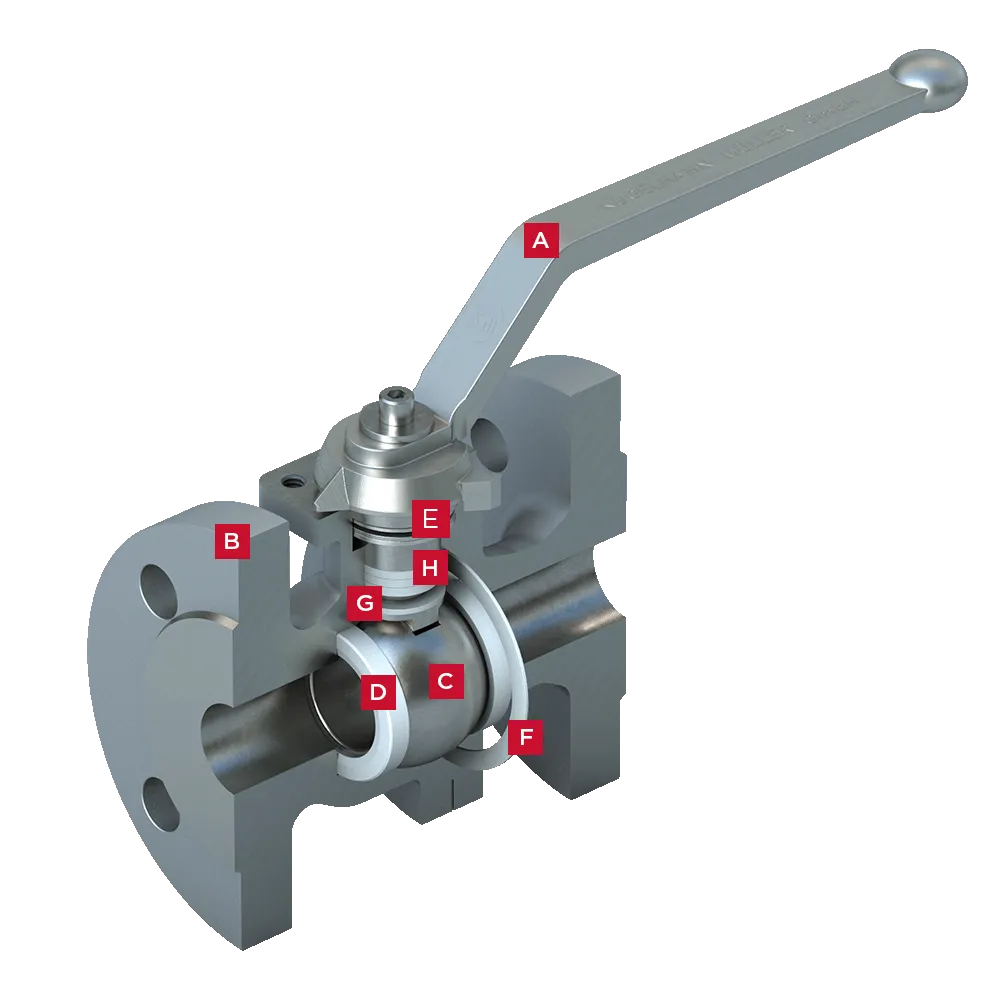

A. Hand Lever

Duplex stainless steel lockable hand lever with a position indicator.

-

B. Body

Robust two-piece body design suitable for heavy-duty applications in multiple industries. A wide range of flange connections are available.

-

C. Ball

Floating full bore design made of polished Duplex stainless steel.

-

D. Seat

Seat design ensures bidirectional zero-leakage sealing under all pressure and temperature conditions.

-

E. Stem

Heavy-duty, blowout-proof stem with “Double D” connection according to ISO 5211 for mounting of various hand levers, adapters, actuators and stem extensions.

-

F. Body Seals

Chambered body seal design to ensure outstanding sealing integrity.

-

G. Stem Packing

Designed with high integrity stem packing arrangement that combines a self-adjusting primary and secondary seal in order to ensure consistent torque and highest possible tightness according to ISO 15848-1.

-

H. PTFE Packing

The PTFE sealing system features a preloaded Belleville spring design with the benefit of optional readjustement.

Explore More Bray Insights

Learn Even More About How Bray’s Solutions Can Impact Your Business

.webp)