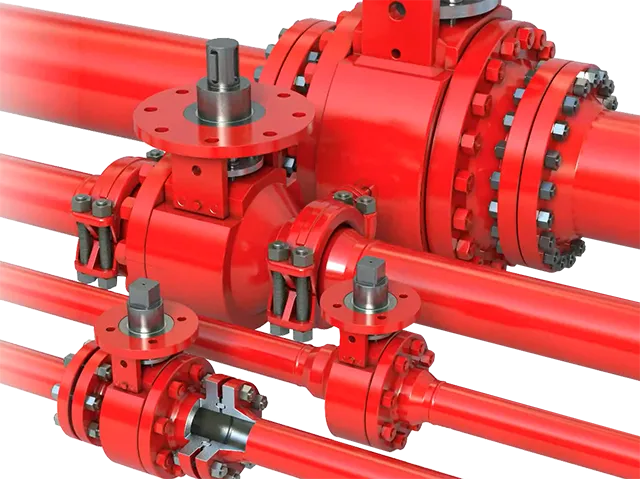

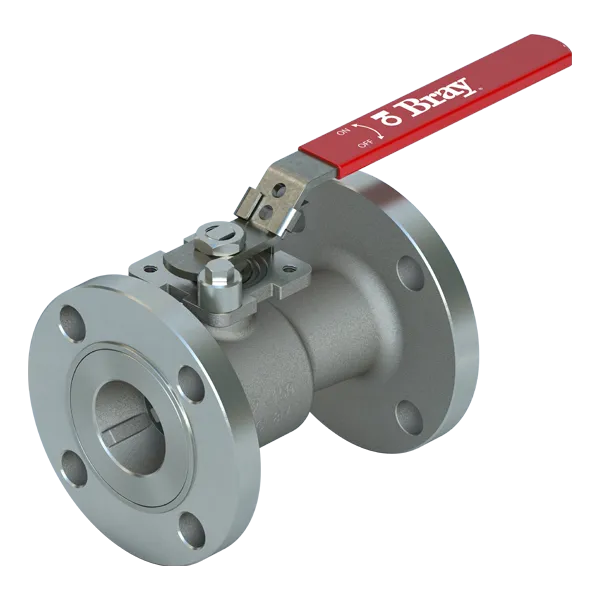

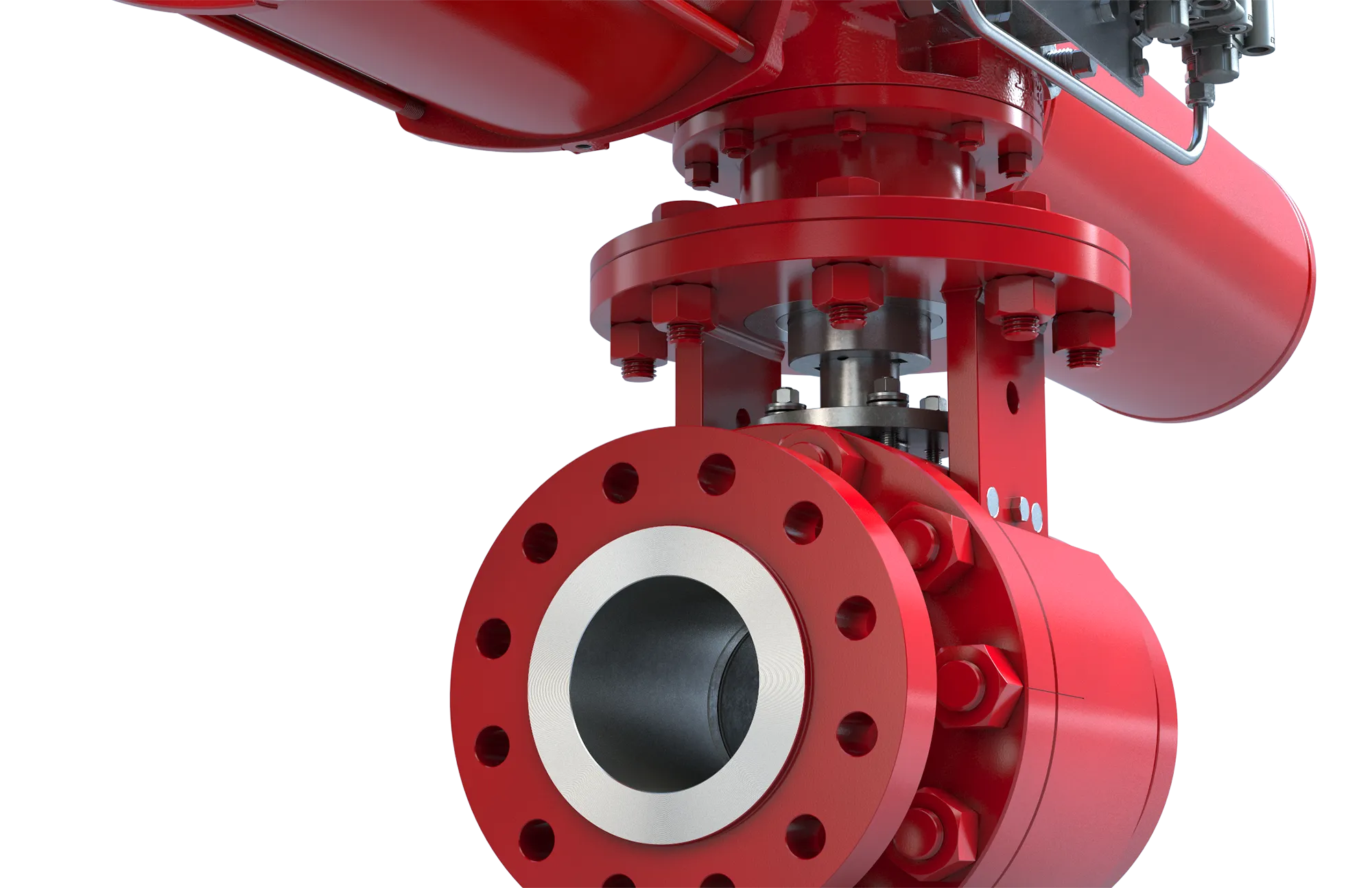

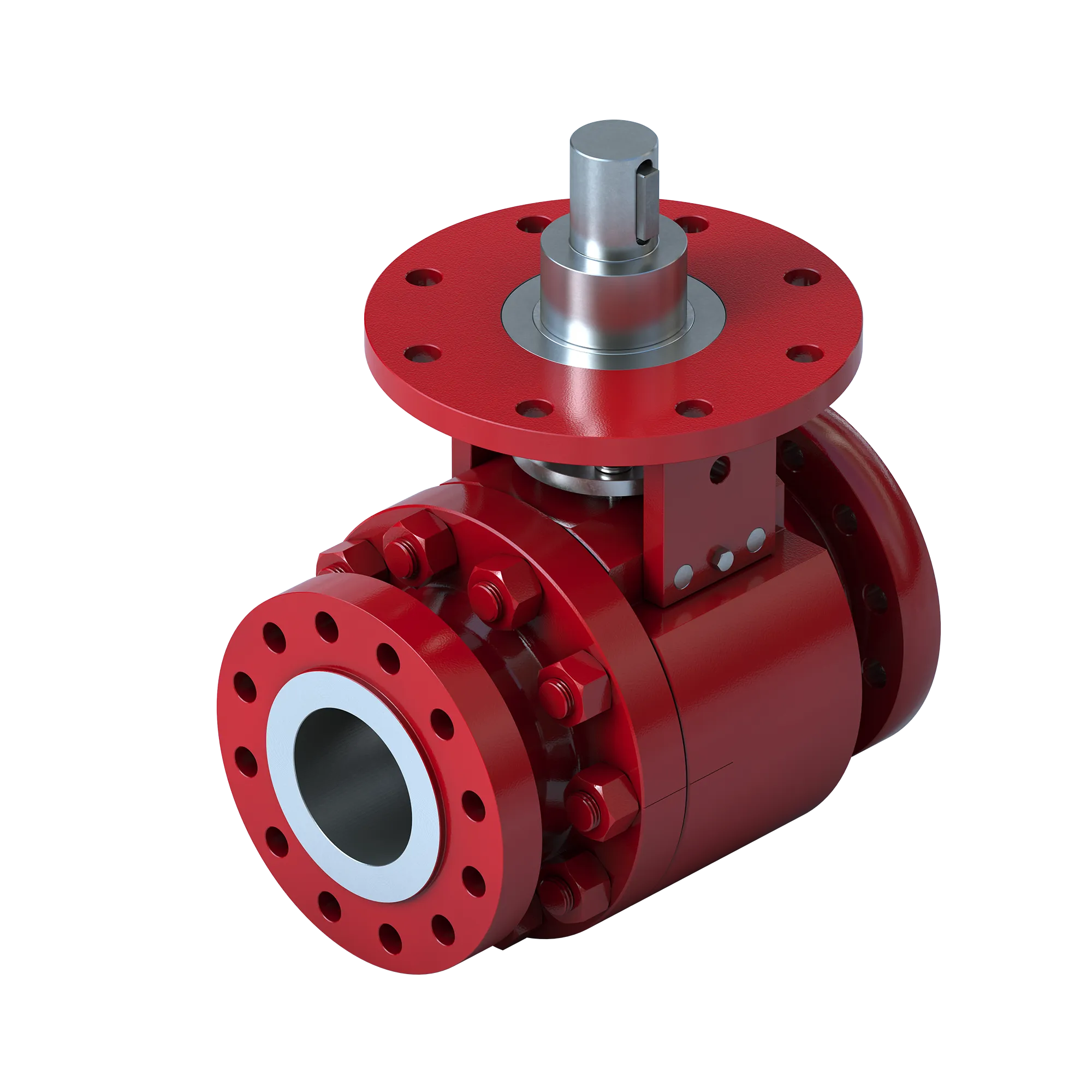

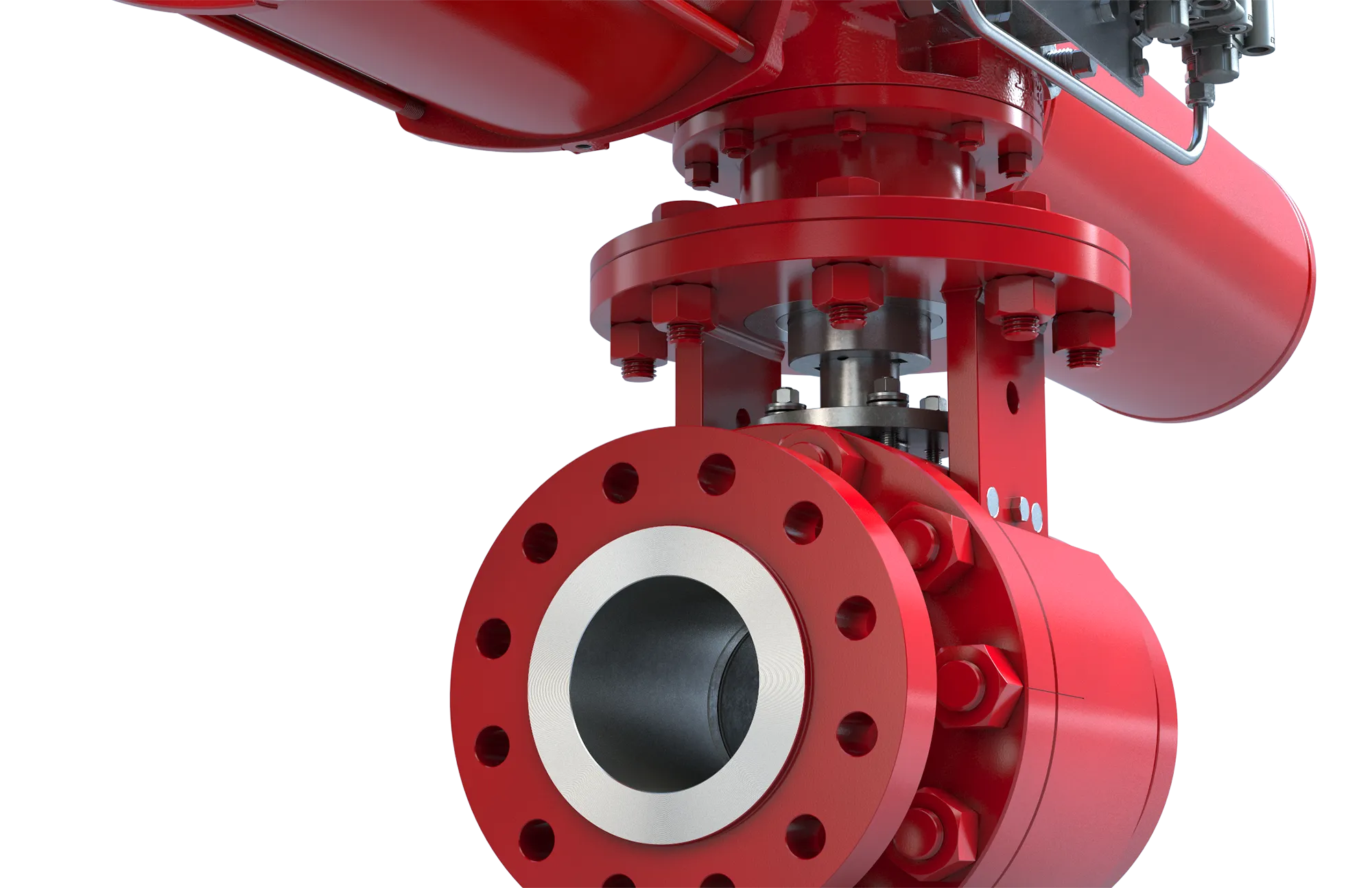

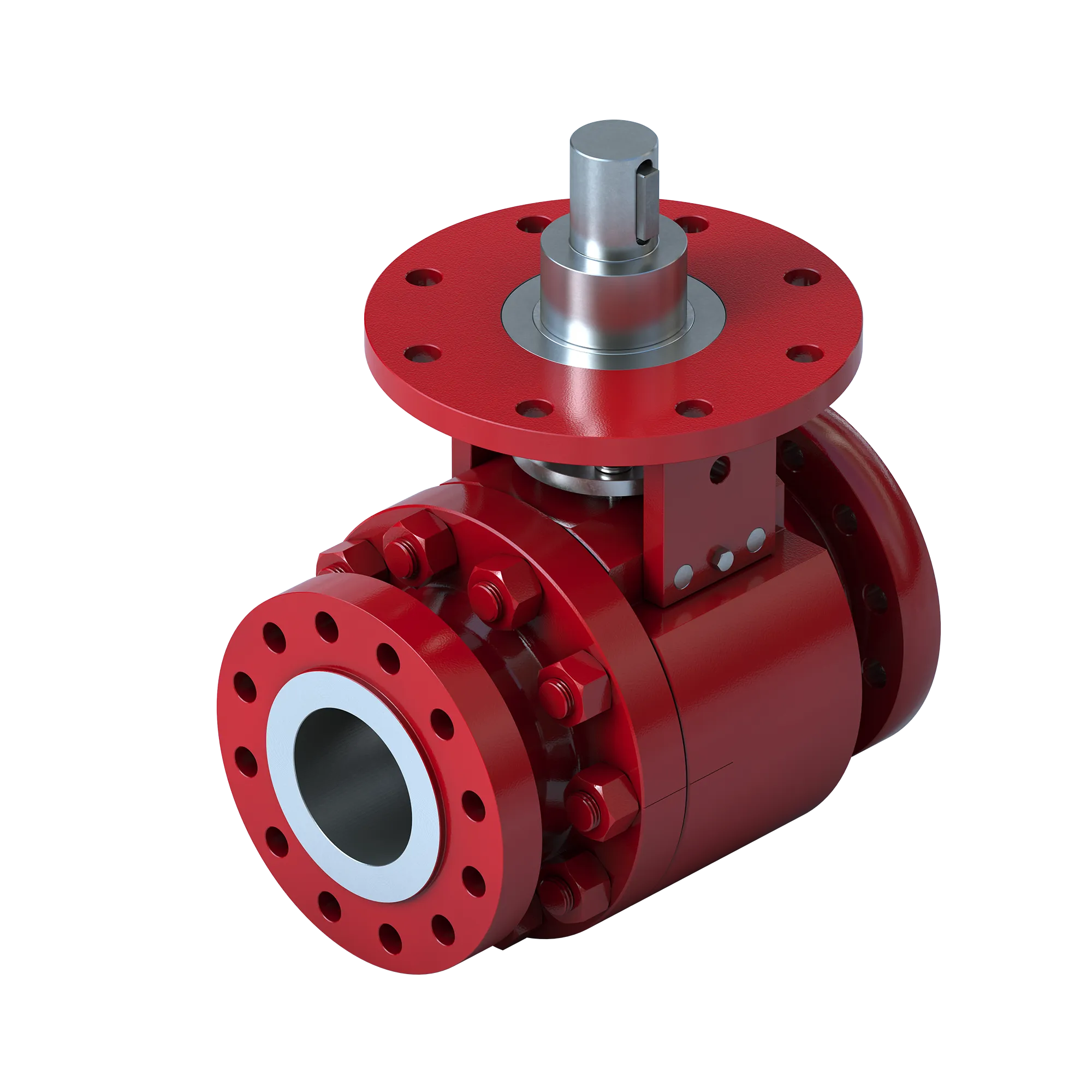

Bray Series M1 Severe Service Metal Seated ball valves deliver exceptional performance and reliability in the most challenging flow control conditions. Series M1 Severe Service isolation valves are used in high temperature, high pressure, corrosive and erosive duty, critical duty and lethal service applications in power, minerals & mining, oil & gas, refining, chemical / petrochemical, agrichemical and specialty industries where absolute safety and reliability is demanded.

Series M1 Severe Service Ball valves are technically superior, featuring a heavy-duty drivetrain, 360° Mate-Lapped ball and seat, live load packings, heavy duty ISO 5211 actuator mounting, an innovative stem alignment method that eliminates stem side loads and ensures long packing life as well as propriety thermal spray coatings technology including HVOF or High Velocity Oxygen Fueled, APS or Atmospheric Plasma Spray, Plasma Transfer Arc PTA, Laser Cladding and other metalized coatings for extended service life in harsh conditions, minimizing downtime.

Series M1 valves are application specific, engineered and manufactured to order, with careful consideration of the process conditions required for your industrial flow control process. Our engineering and process application team are industry leaders with expertise in designing metal seated ball valves and will closely analyze your flow conditions and process chemistry including; temperature, pressure, thermal shock risk, abrasive erosion, corrosion, cavitation, flashing, solids handling and flow velocity in order to select the appropriate materials of construction and valve trim.

As a leading ball valve manufacturer, with 400 locations globally, Bray™ is dedicated to delivering value to our customers with high-performance severe service ball valves designed and manufactured with the highest quality and craftsmanship in the industry.

Severe Service Ball Valve

Series M1

Exceptional Performance in Severe Service Flow Control Applications

High-Performance Valves With Advanced Coatings for Extended Service Life

Industry-Leading Metal-Seated Valves for Power and Mining Sectors

Specifications

Larger Sizes Available upon request

Standard Cast: A216 Gr WCB, A351 GR CF8M, A217 Gr C12 Alloy Steel

(Higher temperatures consult factory)

Optional: Inconel, Incoloys, Titanium, 17-4 PH Stainless Steel, Duplex Stainless Steel

(Higher pressures consult factory)

Optional: Inconel, Incoloys, Titanium, Duplex Stainless Steel, 17-4 PH Stainless Steel

Optional: Inconel, Incoloys, Titanium, Duplex Stainless Steel, 17-4 PH Stainless Steel

ASME Section VIII - Div 1, Appendix 2

Ring Type Joint (ASME B16.5)

Butt Weld (ASME B16.25)

Socket Weld

Grayloc®

Downloads

Recommended Specs

Severe Service Ball Valves Series M1

IOM Manual

Severe Service Ball Valves Series M1

Product Brochure

Ball Valve Overview

Safety Manual

Series F15/F30 Metal Seated and Series M1 Severe Service Ball Valves

Product Brochure

Severe Service Ball Valves Series M1

Application Guide

Severe Service Ball Valves M1 Delayed Coking

Product Brochure

Series M1 Severe Service Metal Seated Ball Valves for Delayed CokingPower Industry

-

Conventional Power

-

Combined Cycle Power Plants

-

Superheated Steam

-

Slurry Discharge Valves

-

Hydromet Pump Isolation

Conventional Power

Combined Cycle Power Plants

Superheated Steam

Slurry Discharge Valves

Hydromet Pump Isolation

Mining & Minerals

-

Pressure Oxidation (POx)

-

High Pressure Acid Leaching

-

Acid Injection

-

Autoclave Slurry Discharge

-

Tailings

Pressure Oxidation (POx)

High Pressure Acid Leaching

Acid Injection

Autoclave Slurry Discharge

Tailings

Refining Industry

-

Delayed Coking

-

Continuous Catalytic Reforming CCR

-

Fluid Catalytic Cracking FCC

-

Visbreaking

-

Hydrotreating

Delayed Coking

Continuous Catalytic Reforming CCR

Fluid Catalytic Cracking FCC

Visbreaking

Hydrotreating

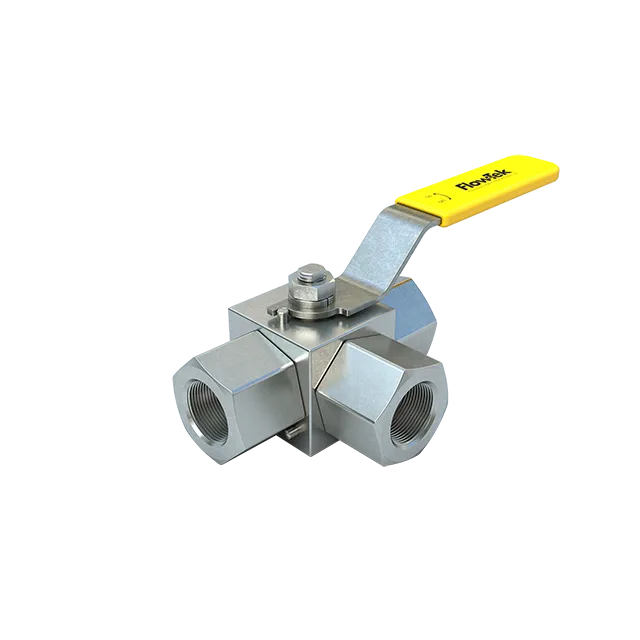

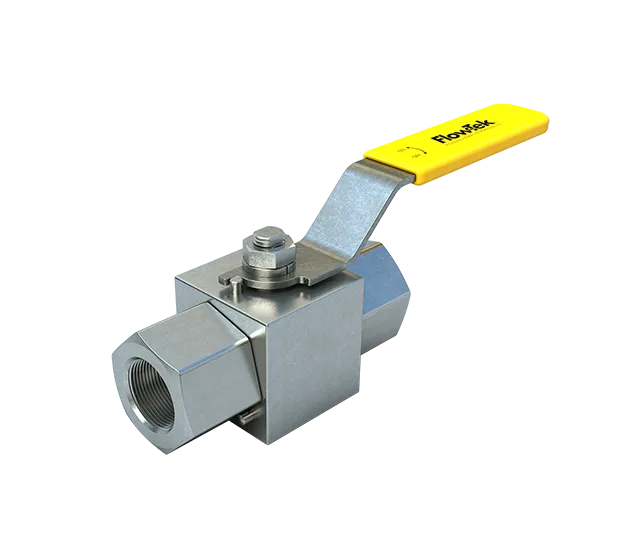

Our Portfolio

Looking for More Solutions?

Discover Our Range of Products Built for Your Industry's Challenges

Explore More Bray Insights

Learn Even More About How Bray’s Solutions Can Impact Your Business

ISO-Certified Cleanroom Solutions for Superior Valve Integrity

Cleanroom Valve Services

Bray's state-of-the-art cleanroom facilities deliver ISO Class 6 to ISO Class 9 precision cleaning around the globe where valves are cleaned, inspected, bagged & tagged to meet the most stringent global standards, ensuring contamination-free valves.

Discover Our Precision Cleaning Solutions