Bray solutions for

Food & Beverage

Beverage production requires strict hygienic conditions to prevent any microbial contamination througout the production facility. These valves are regulated by national and international regulatory standards from various independent organizations such as FDA. These valves are manufactured very carefully to avoid entrapment of food and products particles allowing microorganisms to accumulate. The materials used in valves should be inert or non-reactive to both the product and cleaning substances. Moreover, the valves must also be corrosion-resistant and nontoxic. Generally, stainless steel is ideal for manufacturing direct contact valves for the food and beverage industry.

-

Milk & Dairy

-

Baked Goods

-

Candy

-

Coffee

-

Steam Peeling

-

Frozen Foods

-

Alcohol

-

NSF-61 Approved

-

Quick Clamp Fittings

-

Extended Welding Tube

-

Electropolished Internals

-

Body Cavity Fillers

-

FDA Approved PTFE Seats & Seals

-

TFM Liners for Butterfly Valves

-

Multi-port Valves

-

Custom Valves

Bray Solutions for

Sanitary Valves

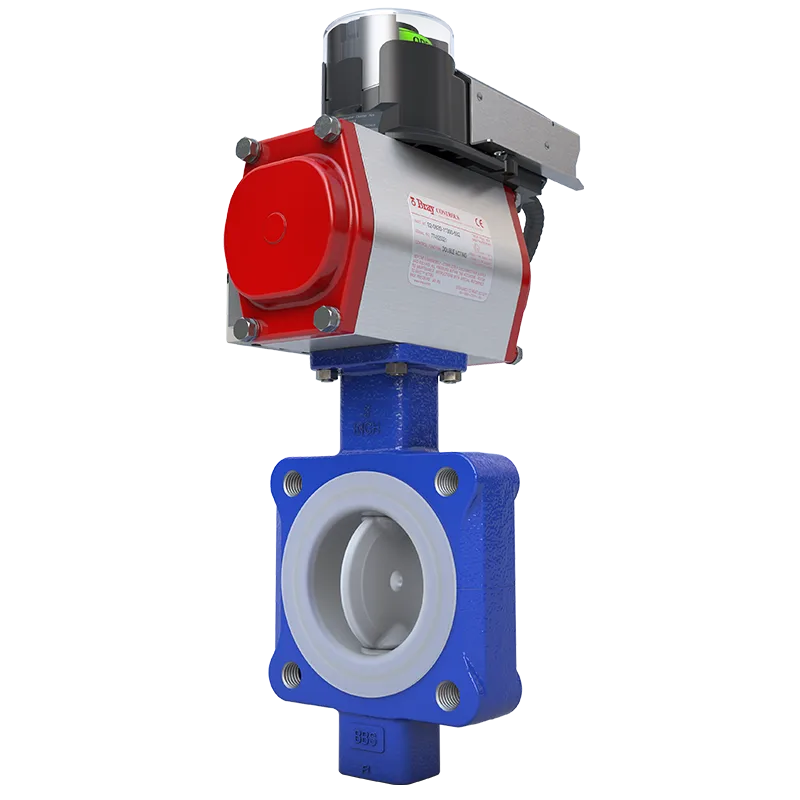

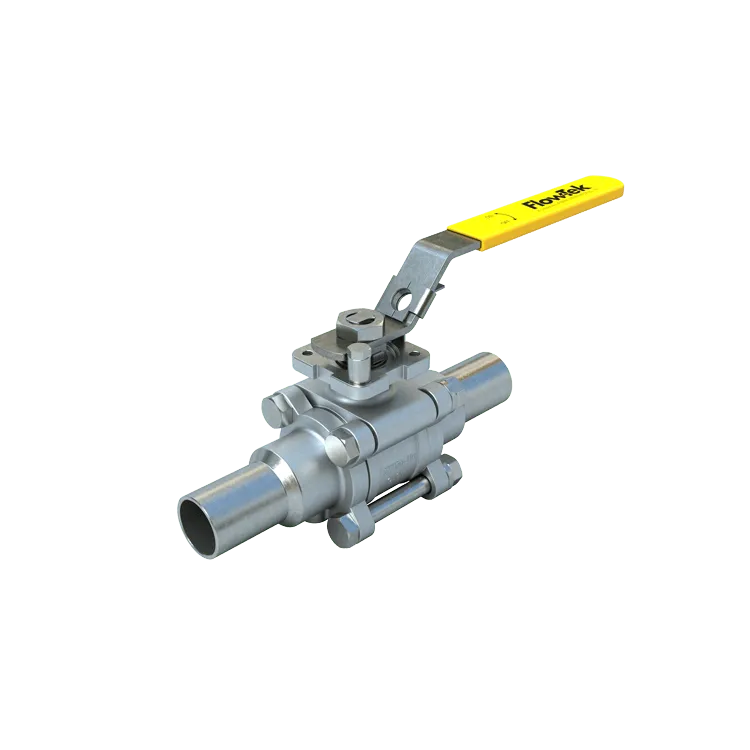

Food & Beverage companies are highly regulated, requiring valves engineered to prevent accumulation of particulates and bacteria within the food product contact valves, in order to ensure, strict regulatory requirements from organizations including the Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA). Bray's 3 Piece Series 7500 / Series 7700 Micro Pure line of 3 Piece ball valves feature full stainless steel construction, tube bore port sizes, FDA approved PTFE seats and seals, Electropolished internal surface finish of 15 Ra-20 Ra and multiple configurations for closures including Extended tube connections for pipe welding and Quick Clamp connections for Clean-in-place (CIP) operations. Bray also offers Body cavity inserts, additional electro-polishing and bag / tag services for FDA valves. Bray also offers butterfly valves with thin disc profiles and improved stem sealing that are well suited for clean in place (CIP) application.

Bray solutions for

Utility Valves

Utility valves account for a large portion of valves found in Food & Beverage plants. Utility valves are considered balance-of-plant valves for heating, cooling, chillers, steam, compressed air, nitrogen, cryogenic liquids, cleaning liquids such as sodium hydroxide, chlorine and other sanitizers. Many of which are used for External Washdowns and Spraydowns of equipment. Bray manufactures a wide variety of utility Ball and Butterfly valves sucha s the Series 20/21, tank bottom, F15/F30 Flanged Ball Valves and more to address any utility valve application along with Bray's global reputation for dependability and exceptional after sales support.

Bray solutions for

NSF-61 Water Valves

Bray is committed to delivering high quality valves certified to NSF/ANSI/CAN 61 and NSF/ANSI/CAN 372, meeting the requirements of the U.S. EPA’s Safe Drinking Water Act (SDWA). All Bray NSF valves have passed a rigorous certification program involving product testing, material verification, and annual manufacturing site inspections. Our NSF-61 Certified valves guarantee safe levels of lead and other harmful contaminates, ensuring safe water sources for food and beverage plants.

Certified and Trusted

By thousands of companies worldwide

Our performance tested products are in compliance with a variety of global certifications and approvals, including FDA, EFSA, NSF, Lloyd's Register, UL, and more.

Explore More Bray Insights

Learn Even More About How Bray’s Solutions Can Impact Your Business