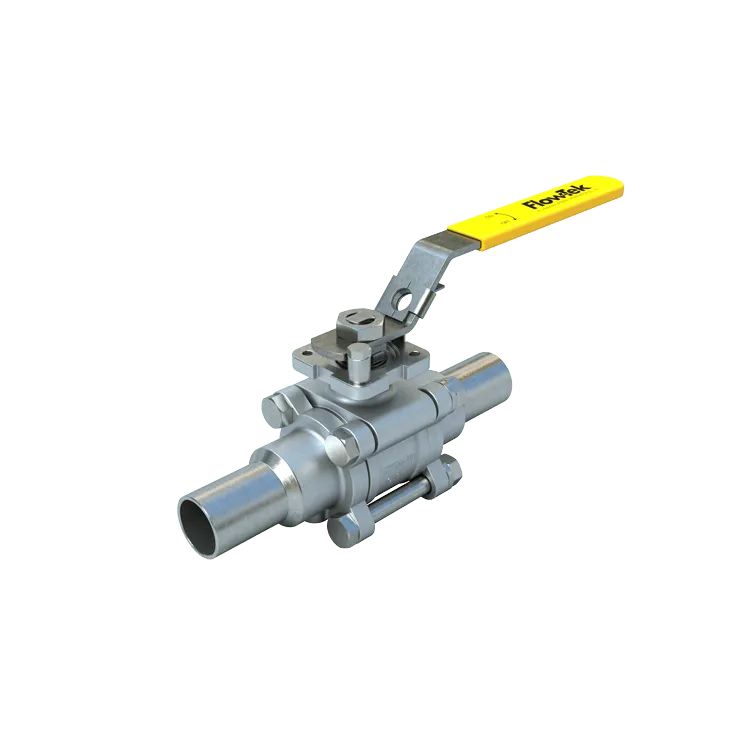

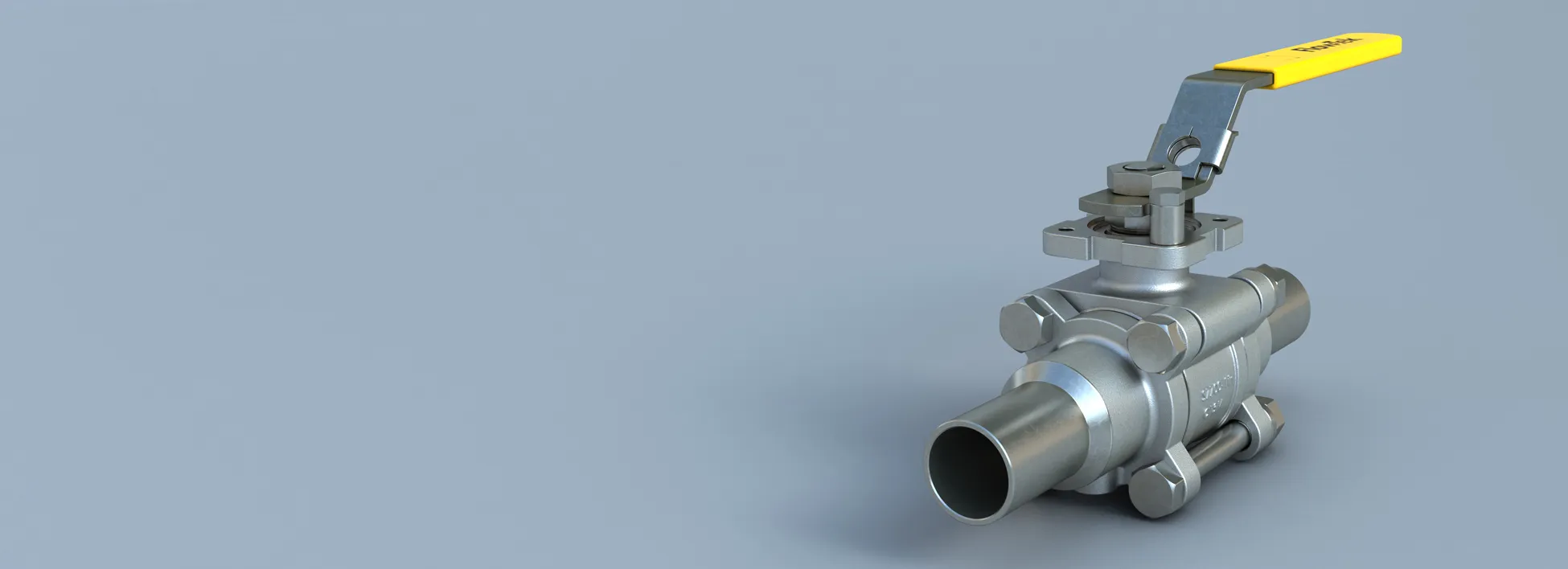

3-Piece Ball Valve

Series S7500/S7700 Micro Pure

High-Purity Ball Valves with FDA-Approved and USP Class VI-Compliant Materials

FDA-Approved and USP Class VI Materials

Ball Valve with 316L Stainless Steel and 15 Ra to 30 Ra Finish for Aseptic Processes

The Series S7500/S7700 Micro Pure 3-Piece Ball Valve is engineered to meet the rigorous safety, and aseptic demands of high-purity applications in pharmaceuticals, biotechnology, semiconductor manufacturing, and food & beverage industries.

Constructed from investment cast CF3M (316L) stainless steel and boasting a finish of 15 Ra to 20 Ra on all internal wetted surfaces, the Series S7500/S7700 Micro Pure series valve ensures superior sanitary operation, and compliance with ASME BPE specifications, governing the design of equipment used in bioprocessing, pharmaceuticals, and personal-care product industries.

Micro Pure series valves are available with body cavity fillers, and purge ports upon request and are available with tube end and extended tube end connections for weld-in-place application as well as quick clamp connections for in-line servicing. For more specialized needs, cavity fillers and purge ports can be added upon request.

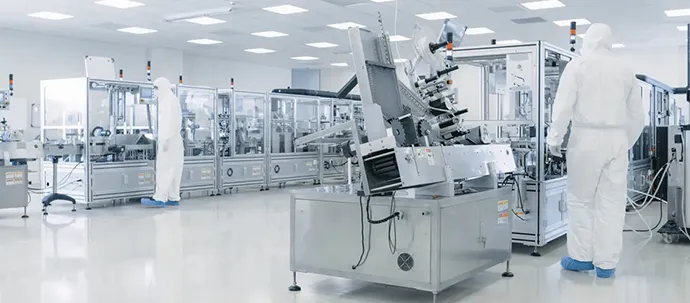

To maintain the highest purity standards, Micro Pure valves are solution cleaned, assembled, and bagged in Bray Cleanroom facilities for use in sanitary applications.

Constructed from investment cast CF3M (316L) stainless steel and boasting a finish of 15 Ra to 20 Ra on all internal wetted surfaces, the Series S7500/S7700 Micro Pure series valve ensures superior sanitary operation, and compliance with ASME BPE specifications, governing the design of equipment used in bioprocessing, pharmaceuticals, and personal-care product industries.

Micro Pure series valves are available with body cavity fillers, and purge ports upon request and are available with tube end and extended tube end connections for weld-in-place application as well as quick clamp connections for in-line servicing. For more specialized needs, cavity fillers and purge ports can be added upon request.

To maintain the highest purity standards, Micro Pure valves are solution cleaned, assembled, and bagged in Bray Cleanroom facilities for use in sanitary applications.

Specifications

Size Range

½ - 4" (12 - 100mm)

Body Materials

CF3M

Temperature Range

-50°F to 450°F (-46°C to 232°C)

Stem Materials

316

Maximum Allowable Operating Pressure

1000psi WOG

Seat Materials

Standard: PTFE, Optional: TFM 1600, UHMWPE, Cavity Fillers

Shutoff Rating

Zero Leakage

Ball Materials

CF3M

Body Style

Three Piece

Design Standard

ASME BPEa

End Connections

Quick Clamp, Extended Tube End, SAE Male

Testing Standard

MSS SP 61

Certifications

USP Class VI

Ports

Tube Bore Port: ½ - 2"

Face to Face

Manufacturers standard

Steam Rating

150psi WSP

applications

High Purity, Semi Conductor, Food & Beverage

Downloads

Technical Bulletin

Ball Valves Actuator Selection Guide

Download

English

Product Brochure

Flow-Tek® Micro Pure Series S7500 | S7700 3 Piece Tube Bore Ball Valves

Download

English

Selection Guide

Flow-Tek® Part Number Selection Guide MicroPure

Download

English

Product Brochure

Ball Valve Overview

Download

English

Our Portfolio

Looking for More Solutions?

Discover Our Range of Products Built for Your Industry's Challenges.

Explore More Bray Insights

Learn Even More About How Bray’s Solutions Can Impact Your Business

Reliable Multi-Port and Custom Valves for Pharmaceutical Manufacturing Processes

Pharmaceuticals & Biotechnology

Bray provides innovative Valve Solutions to Pharmaceutical and Biotech Companies, enhancing efficiency and agility while reducing costs in a competitive landscape.

Bray Pharma & Biotech Solutions