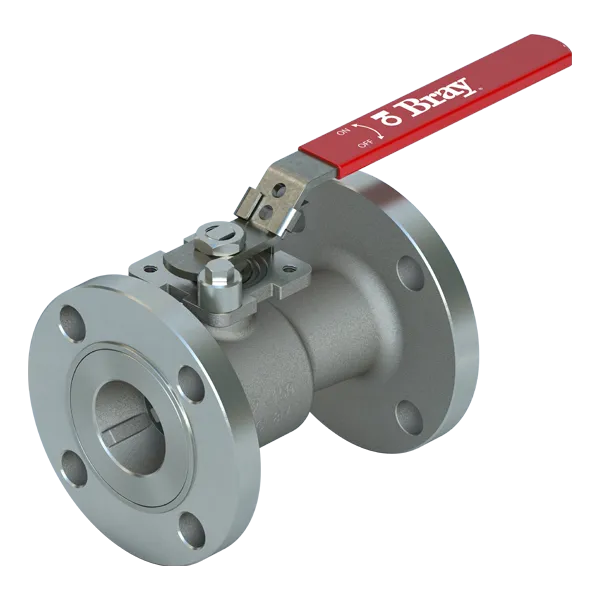

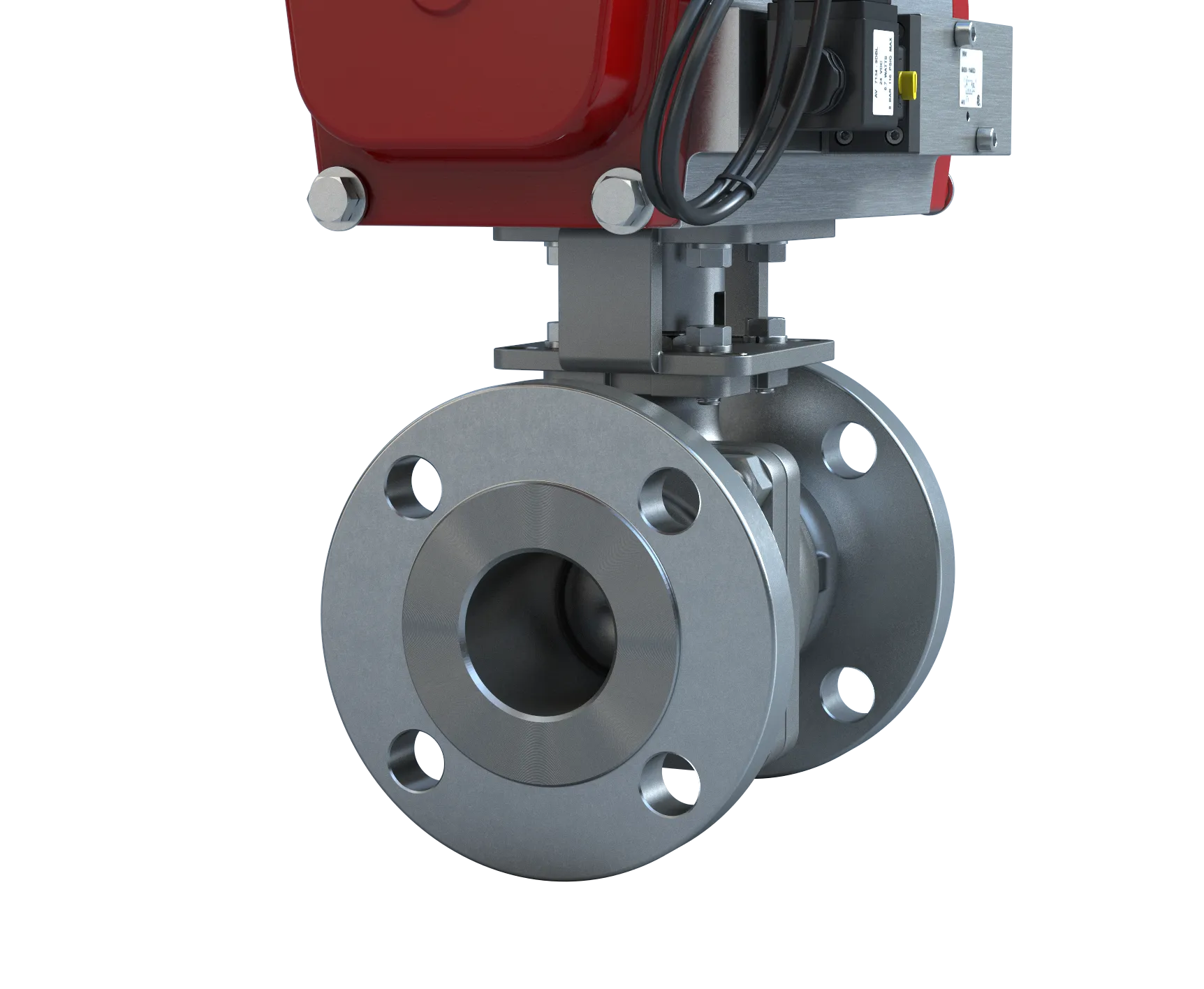

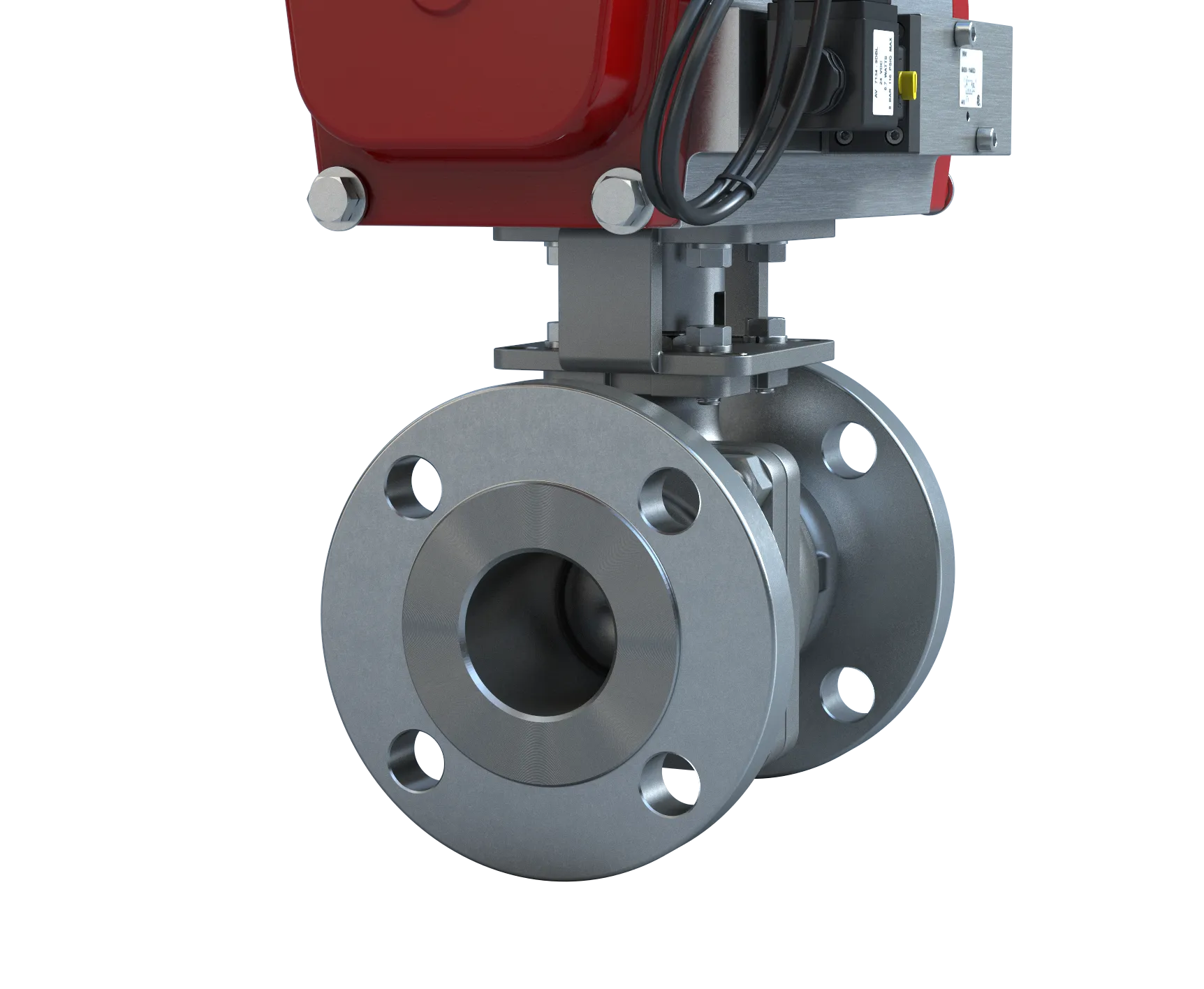

Flanged Ball Valve

Series F15/F30

Adjustable Stem Packing and Trunnion Support for High-Cycle Applications

Stainless and Carbon Steel Construction

Fire-safe designs meet API 607 standards for high-temperature safety compliance

Series F15/F30 Flanged Floating Ball Valves are investment cast, ASME B16.34 Class 150 & Class 300 full port ball valves. They are available in a variety of optional trims and configurations, including V-ball control valve trims, and are used in virtually every industry across the globe. Series F15/F30 ball valves offer exceptional value and dependable operation across a wide range of service conditions in a rugged flanged ball valve design.

Series F15/F30 flanged ball valves are engineered to ensure bubble-tight shutoff and low operating torque. ½” – 2” sizes feature Bray’s Smart Stem™ technology with integral live load packing. 2 ½” – 12” sizes utilize an independent packing gland which can be easily adjusted without removing mounting hardware or operator. The packing gland is contoured to uniformly distribute the load across the packing. The live load packing is self-adjusting due to its Belleville washers allowing it to compensate for environmental changes and wear, ensuring maintenance free operation and long cycle life. Larger sized F15/F30 flanged Ball Valves also feature a trunnion-type ball support that reduces operating torque.

Resilient seated F15/F30 flanged ball valves feature positive preloading to ensure low pressure/vacuum sealing capability. All resilient seat materials ensure bi-directional, bubble-tight sealing. All resilient seat materials ensure bi-directional, bubble-tight sealing.

Series F15/F30 flanged ball valves are available in stainless steel (CF8M), carbon steel (WCB), and specialty alloys such as Alloy 20, Hastelloy, and other exotic alloys upon request. Non-fire safe versions are available with standard stem seals. API 607 fire safe trims utilize graphite stem seals. Series F15/F30 valves offer ease of automation with an integral-cast ISO 5211 mounting pad. *

* Not available in all sizes, consult product brochure for details.

Series F15/F30 flanged ball valves are engineered to ensure bubble-tight shutoff and low operating torque. ½” – 2” sizes feature Bray’s Smart Stem™ technology with integral live load packing. 2 ½” – 12” sizes utilize an independent packing gland which can be easily adjusted without removing mounting hardware or operator. The packing gland is contoured to uniformly distribute the load across the packing. The live load packing is self-adjusting due to its Belleville washers allowing it to compensate for environmental changes and wear, ensuring maintenance free operation and long cycle life. Larger sized F15/F30 flanged Ball Valves also feature a trunnion-type ball support that reduces operating torque.

Resilient seated F15/F30 flanged ball valves feature positive preloading to ensure low pressure/vacuum sealing capability. All resilient seat materials ensure bi-directional, bubble-tight sealing. All resilient seat materials ensure bi-directional, bubble-tight sealing.

Series F15/F30 flanged ball valves are available in stainless steel (CF8M), carbon steel (WCB), and specialty alloys such as Alloy 20, Hastelloy, and other exotic alloys upon request. Non-fire safe versions are available with standard stem seals. API 607 fire safe trims utilize graphite stem seals. Series F15/F30 valves offer ease of automation with an integral-cast ISO 5211 mounting pad. *

* Not available in all sizes, consult product brochure for details.

Specifications

Size Range

NPS ½ to 12 / DN 15 to 300

Body Materials

Stainless Steel (CF8M), Carbon Steel (WCB), Special Alloys

Temperature Range

-50°F to 650°F (-46°C to 343°C)

Stem Materials

ASTM A479 Type 316

Maximum Allowable Operating Pressure

F15: ASME Class 150

F30: ASME Class 300

PN10, 16, 25, 40

F30: ASME Class 300

PN10, 16, 25, 40

Seat Materials

Standard: TFM 1600

Optional: Tek-Fil®*, PEEK, RPTFE, UHMWPE, Metal

Optional: Tek-Fil®*, PEEK, RPTFE, UHMWPE, Metal

Shutoff Rating

Zero Leakage

Ball Materials

ASTM A351 Gr CF8M

Body Style

Two Piece

End Connections

ASME Class 150, 300

EN 1092 PN10, 16, 25, 40

EN 1092 PN10, 16, 25, 40

Certifications

API 607, ATEX, CRN, NACE MR0175, NSF 61/372, PED, PE(S)R, SIL, TR CU

Ports

Full Port

Accessories

Body Cavity Fillers, Media Containment Unit, Resolute Square Ball, V Ball, Globe Valve Face-To-Face

Face to Face

ASME B16.10

Design Standard

ASME B16.34, API 608

Testing Standard

API 598

applications

Process, Tank Farms, Fueling, Oil & Gas, Municipal Water Supply

Downloads

Sales Data Sheet

Series F15/F30 and RF15/RF30 Floating API 608 & Fugitive Emissions Applications

Download

English

Product Brochure

Flanged Ball Valves Series F15/F30

Download

English

Product Brochure

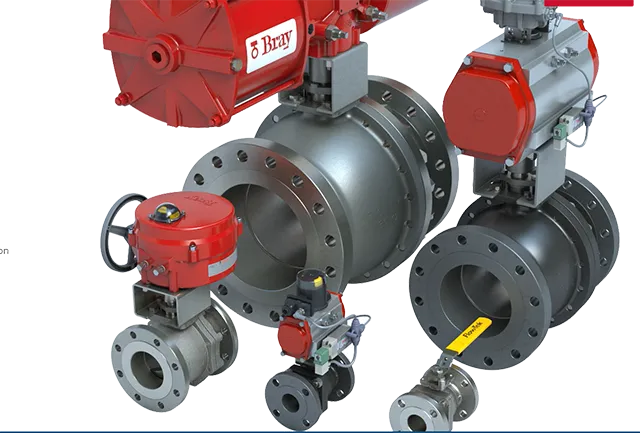

Ball Valve Overview

Download

English

IOM Manual

2-piece Flanged Full Port Ball Valves Series F15/F30 Soft Seated

Download

English

Safety Manual

Series F15/F30 and RF15/RF30 Quarter Turn Flanged Floating Ball Valves

Download

English

Technical Bulletin

Ball Valves Actuator Selection Guide

Download

English

Recommended Specs

Series F15 / F30 Floating, Flanged Ball Valves

Download

English

Technical Bulletin

Ball Valves Seat Materials Tek-Fil®

Download

English

Selection Guide

Part Number Selection Guide F15/F30

Download

English

Technical Bulletin

Ball Valves Seat Materials PEEK

Download

English

Certification

NSF/ANSI/CAN 61 & 372 Certified Ball Valves

Download

English

Our Portfolio

Looking for More Solutions?

Discover Our Range of Products Built for Your Industry's Challenges

Explore More Bray Insights

Learn Even More About How Bray’s Solutions Can Impact Your Business

ISO-Certified Cleanroom Solutions for Superior Valve Integrity

Cleanroom Valve Services

Bray's state-of-the-art cleanroom facilities deliver ISO Class 6 to ISO Class 9 precision cleaning around the globe where valves are cleaned, inspected, bagged & tagged to meet the most stringent global standards, ensuring contamination-free valves.

Discover Our Precision Cleaning Solutions