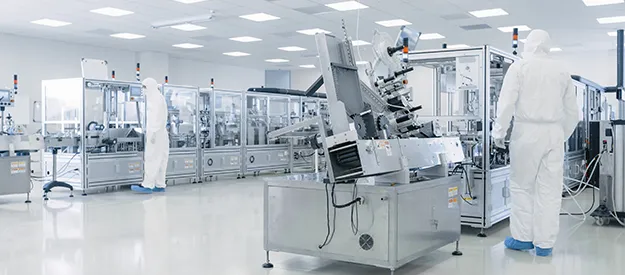

Bray Solutions for

Biotechnology & Pharmaceutical Manufacturing

Biotechnology is helping to improve our lives by harnessing genetics to create medicines from biologics while pharmaceutical companies use chemistry to do the same, both healing lives. Bray manufactures a full line of valves, actuators, controls and accessories in Stainless Steel and exotic alloys for use across a wide array of applications in both Pharmaceuticals and Biotechnology. Bray products are known globally for their high quality and reliability.

-

FDA Approved Materials

-

BPE Approved

-

NSF-61 Approved

-

Tube Bore Port Sizes

-

Caustics Handling

-

Stainless Steel & Exotic Alloys

-

Extended Tube End Fittings

-

Clean-In-Place Fittings

-

Electropolished Internals

-

Body Cavity Fillers

-

Virgin PTFE Seats and Seals

-

TFM Liners for Butterfly Valves

-

Multi-port Valves

-

Custom Valves

Bray Solutions for

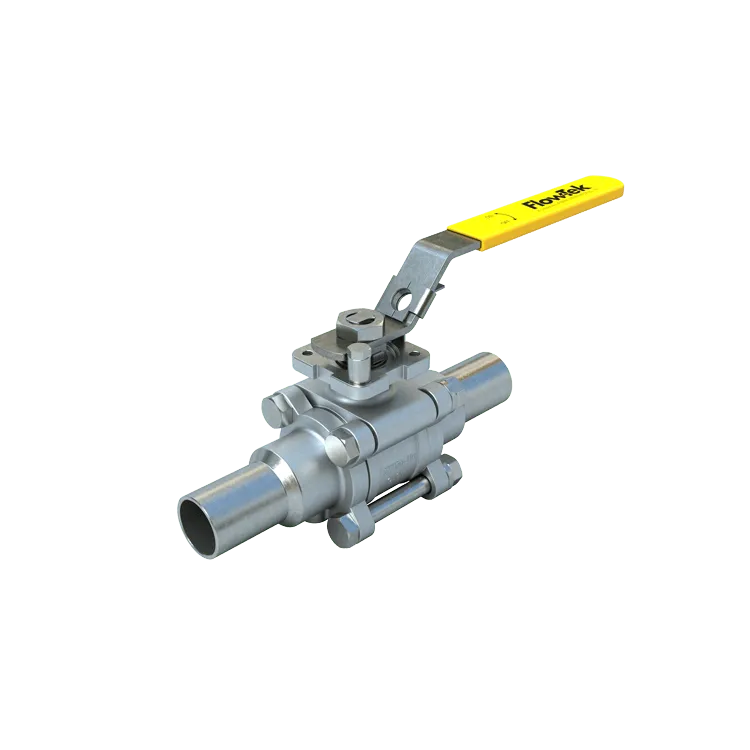

Sanitary Valves

Many applications in the Pharma and Biotech industry rely on sanitary or aseptic valves engineered to comply with strict regulations from agencies including the Food and drug administration (FDA) and European Medicines Agency (EMA). Sanitary and aseptic valves ensure safe operation by preventing entrapment of debris within crevice, pits, and grooves within the valve body, where bacteria can grow. Bray 3-Piece Sanitary valves are designed to comply with ASME BPEa for High Purity Valves with tube bore port diameter, and FDA approved Virgin PTFE seats and seals. Our sanitary valves are designed for Service-in-Place (SIP) operation with available tube ends, extended tube ends, quick clamp fittings, flanged fittings and internal micro polishing. Bray Sanitary valves can also be provided with MTR (Material Test Reports), PMI (Positive Material Identification), LP (Liquid penetrate) and Radiographic examination test reports. Bray also offers butterfly valves with thin disc profiles and improved stem sealing that are well suited for clean in place (CIP) application.

Bray Solutions for

Utility Valves

Utility valves account for a large portion of valves found in Pharmaceutical and biotechnology Manufacturing plants. Utility valves are considered balance-of-plant valves for heating, cooling, chillers, steam, compressed air, nitrogen, cryogenic liquids, cleaning liquids such as sodium hydroxide, chlorine and other sanitizers. Bray manufactures a wide variety of utility valves to address any application, with a global reputation for dependability and exceptional after sales support.

Bray Solutions for

Ultrapure Water and Makeup Water

Ultrapure Water (UPW) for Pharma and Biotechnology is used as a raw material, ingredient, and solvent in the processing, formulation, and manufacture of pharmaceutical products, active pharmaceutical ingredients (APIs) and intermediates, as well as analytical reagents. Biology-Grade-Water suitable for most common Molecular Biology Applications and Pharmaceutical Manufacturing Applications is produced through Reverse Osmosis systems and further processed in polishing systems. Bray Manufactures a complete line of PFA Lined Butterfly Valves and PFTE/PFA-Lined Ball Valves ideal for applications in Reverse Osmosis and water polishing systems.

Certified and Trusted

By thousands of companies worldwide

Our performance tested products are in compliance with a variety of global certifications and approvals, including FDA, EFSA, NSF, Lloyd's Register, UL, and more.

Explore More Bray Insights

Learn Even More About How Bray’s Solutions Can Impact Your Business