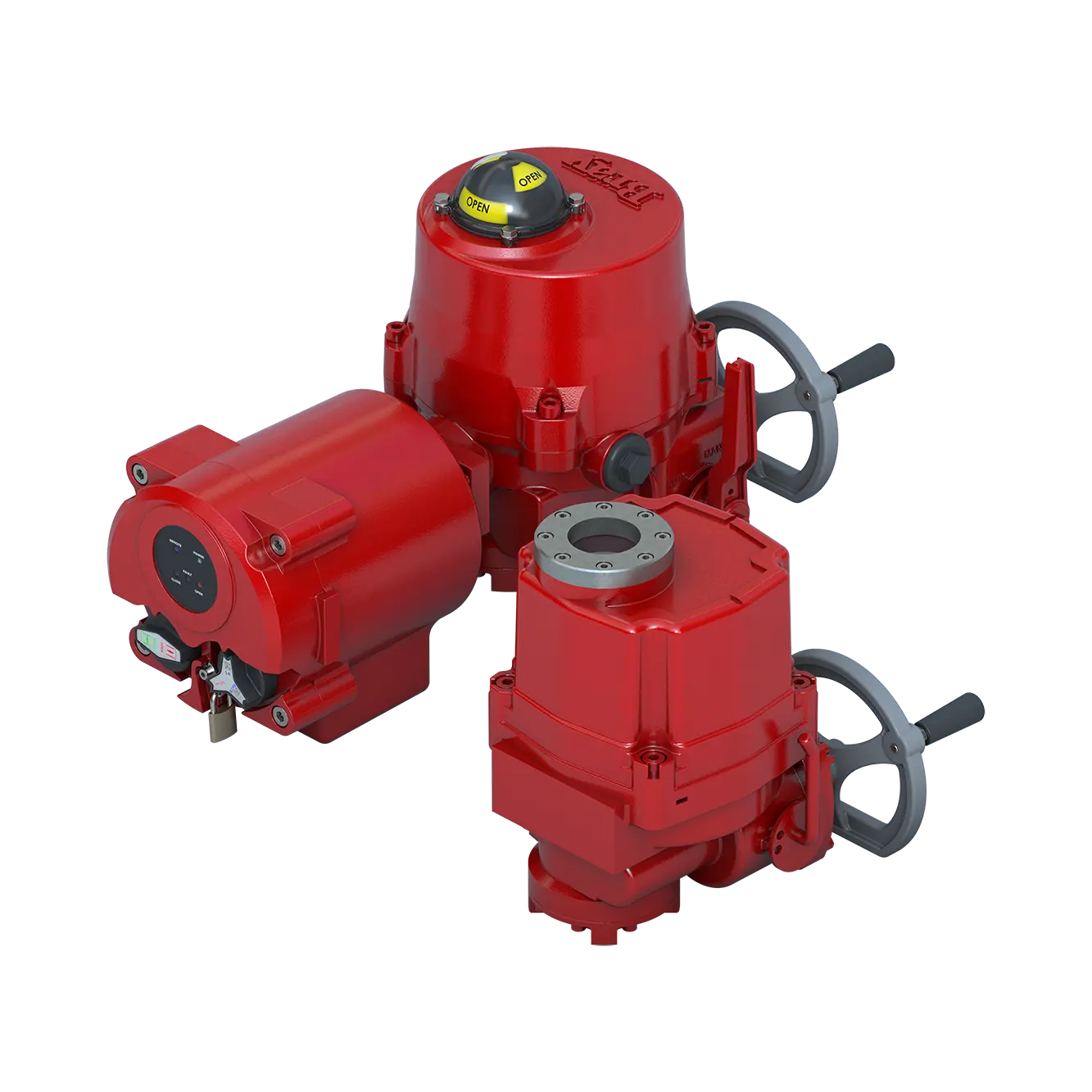

Output Torque 300 in-lb (34 Nm) to 18,000 in-lb (2,034 Nm)

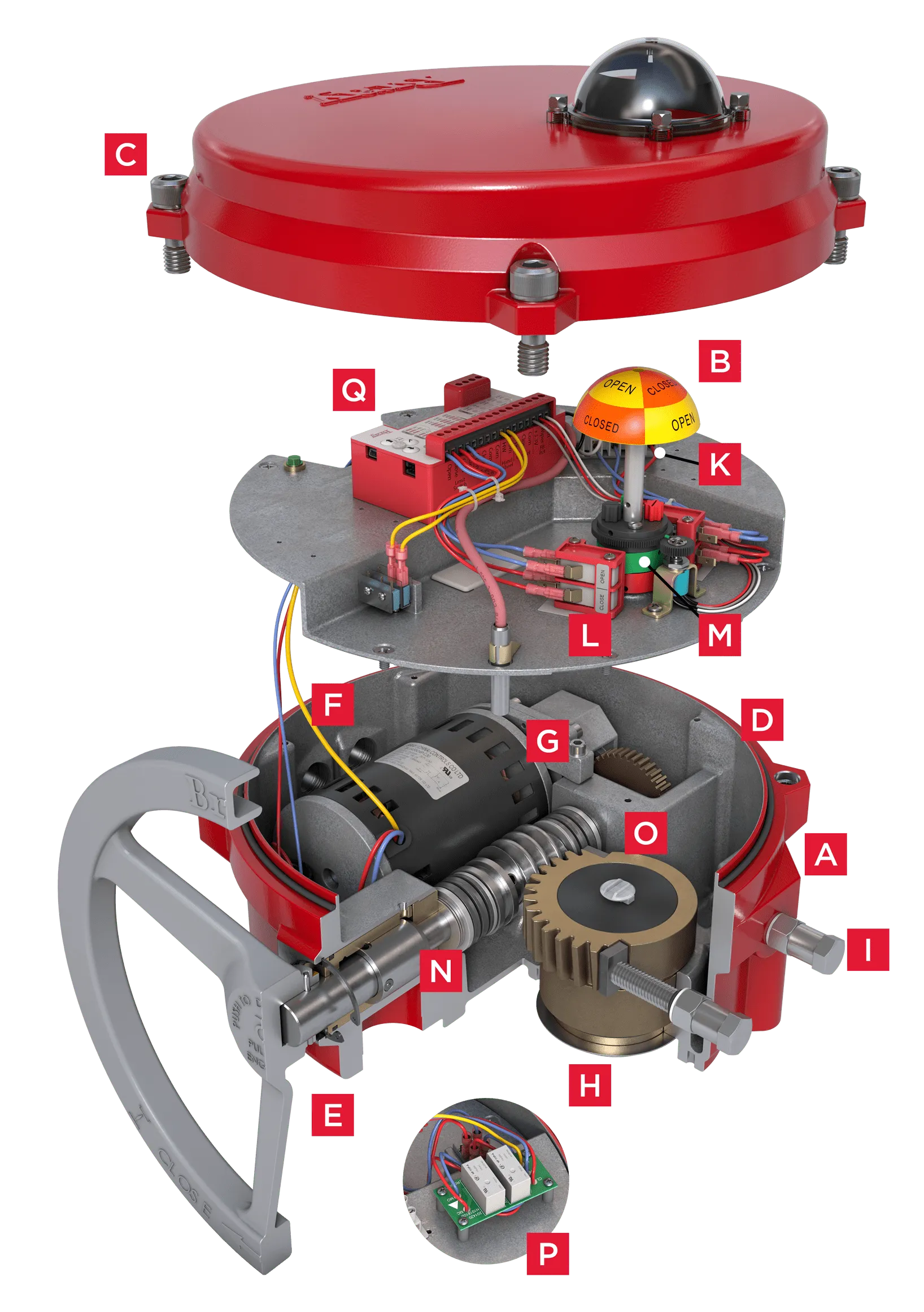

Decades of Bray's proven success in electric actuation, combined with innovative engineering, has produced the Series 70 electric actuator. The Series 70 features on/off or modulating control and offers many advantages over other actuators including:

- UL, CSA and CE certification of most units

- Wiring directly to the terminal strip without interference from other components

- Simple and unique manual override handwheel system

- Lowest profile and lightest weight actuator on the market

- Simple finger or screwdriver adjustment of travel limit cams without interference from other components

- Highly visible valve status display on most units (Heartbeat)