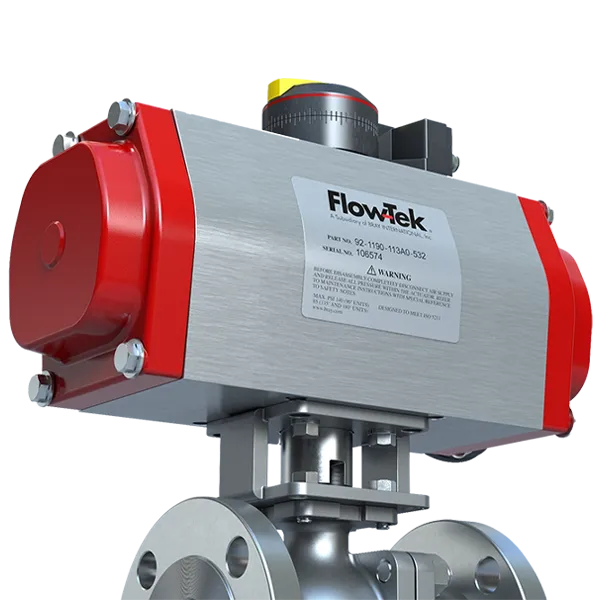

Bray proudly offers the Flow-Tek Series 92/93 rack & pinion, opposed-piston pneumatic actuator, designed to incorporate innovative, high performance features into a compact, rugged, and reliable modular product line. These space-saving,

modular units are self-contained with integral internal porting that reduces the cost of easily damaged external tubing. Units are suitable for both on/off and throttling applications.

Low Friction

With a low coefficient of friction, the Series 92/93 provides superior high-cycle, long lasting service. All piston cylinder walls are honed to a very fine finish and piston guides, piston rings, and output shaft bearings are permanently lubricated and

manufactured from acetal material.

Spring Return

Flow-Tek’s spring return models employ a unique cartridge system. The spring cartridges offer safety, simplicity, and reduced space requirements. The actuator can be easily disassembled and assembled without cumbersome equipment or any danger to the installer. Converting from double acting to spring return actuation is simply a matter of removing the end caps and adding the unique spring cartridges. The housing length of the spring return model is the same as the double acting model, except size 48 units.

Actuator/Accessory Mounting

All Series 92/93 actuators comply with ISO 5211 standards for mounting of actuators to valves. A double square bore (star) in the ouput shaft is standard. Actuators meet NAMUR standards (VDI/VDE 3845) for accessory mounting.

Integral Travel Stops

Adjusting screws that contact a cam assembly on the output shaft precisely limit travel of the actuator to specific degrees of rotation. The travel stops permit bi-directional adjustment of actuator movement in both the open and closed positions.

Stainless Steel Trim

The Series 92/93 is offered with stainless steel body, end caps, and hardware for superior internal and external corrosion resistance. These units are ideal for chemical, pulp & paper, sanitary, food & beverage, marine, mining and pharmaceutical applications.

-copy.webp)