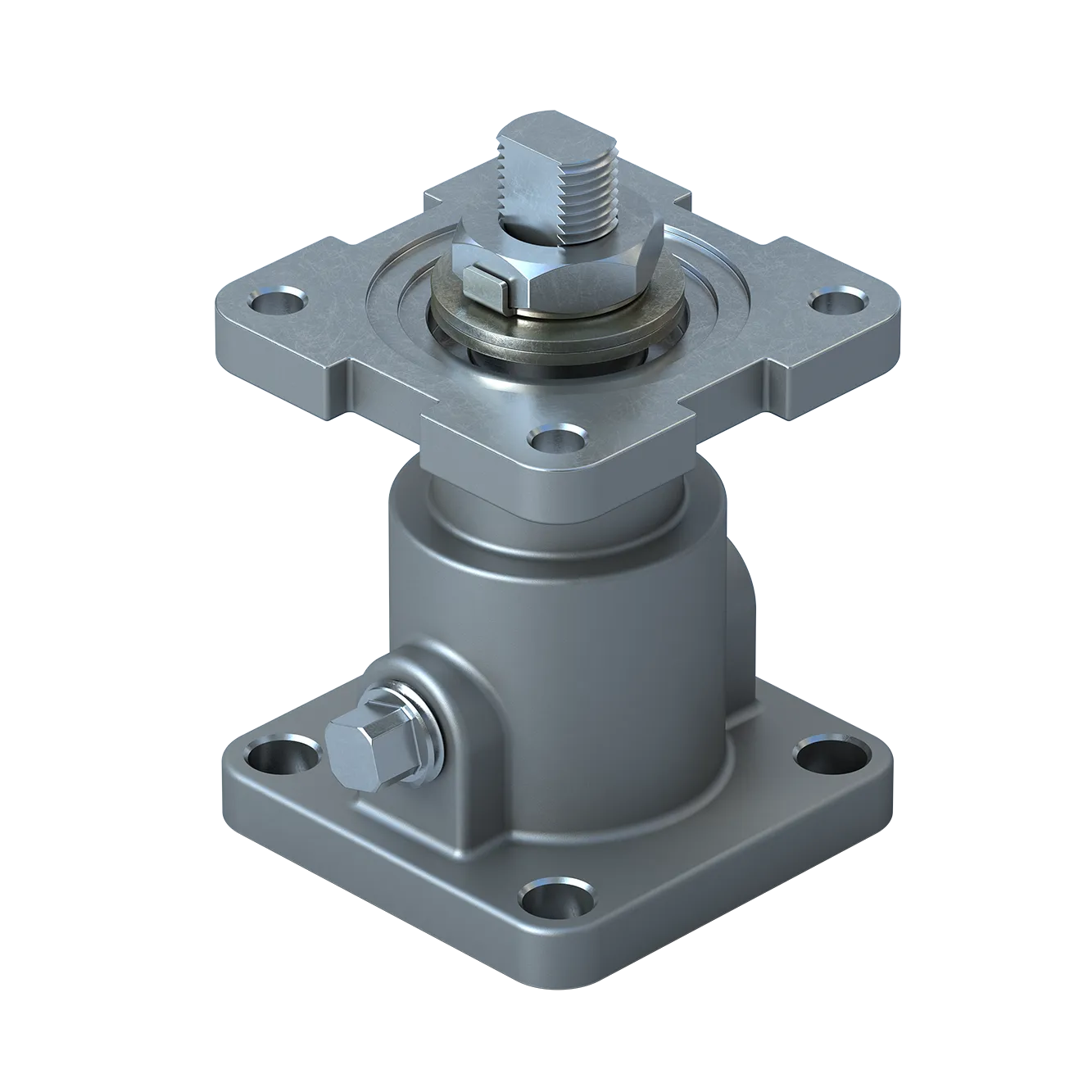

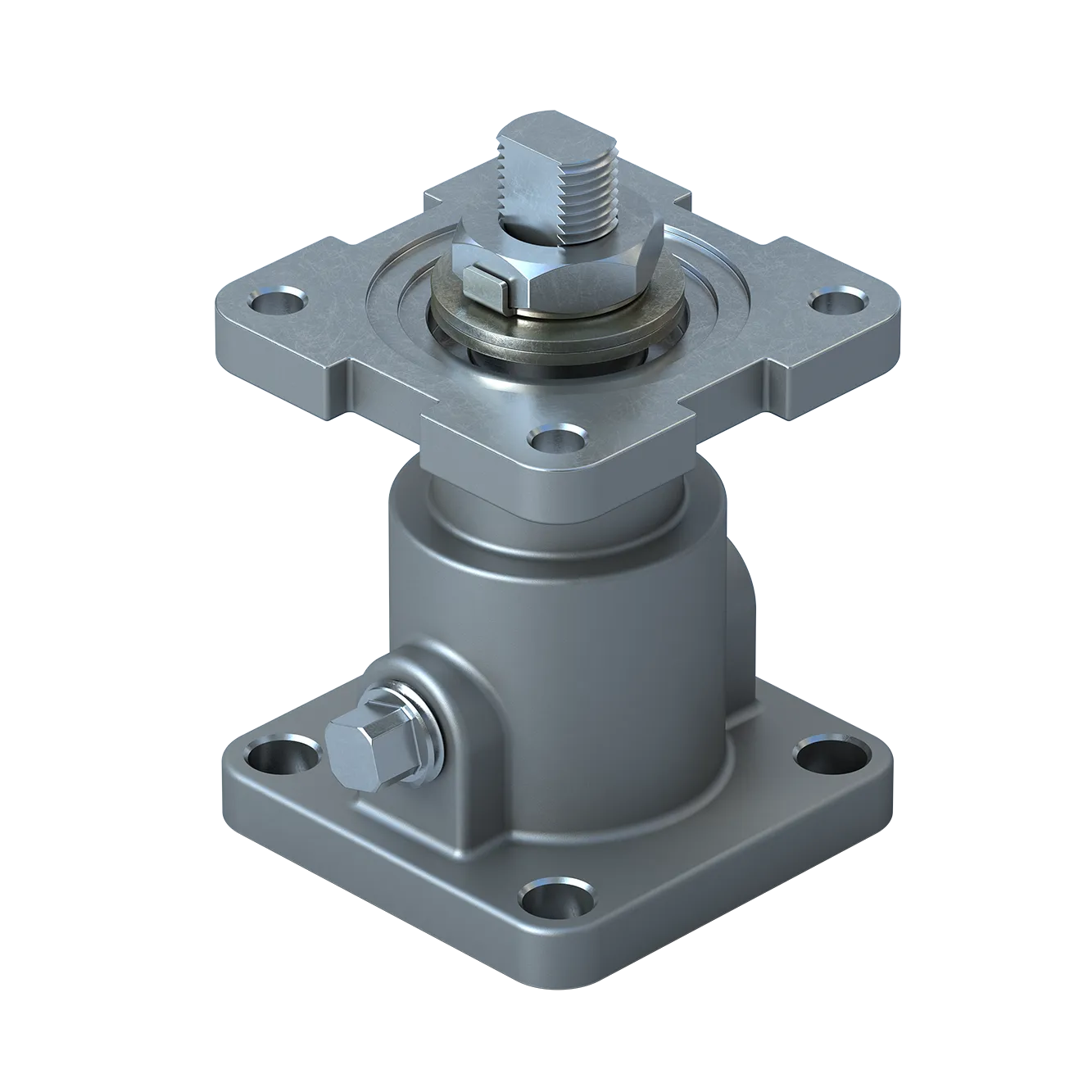

Bray’s Media Containment Unit (MCU) offers unparalleled sealing performance for demanding industrial ball valve applications, including high cycle, low temperature, high-temperature, and steam applications, enhancing safety and environmental protection, ensuring operational reliability and compliance with environmental standards.

Bray’s MCU is designed to prevent unintentional and undesirable emissions, leakage or discharge. In the event of a primary stem seal failure, the MCU’s secondary seal prevents leaks, while the MCU’s side port can be used for fugitive emissions monitoring, leak detection, fugitive emission diversion, as a Positive Pressure Seal, and as an emergency repair mechanism, enabling sealant injection through a button head check valve.

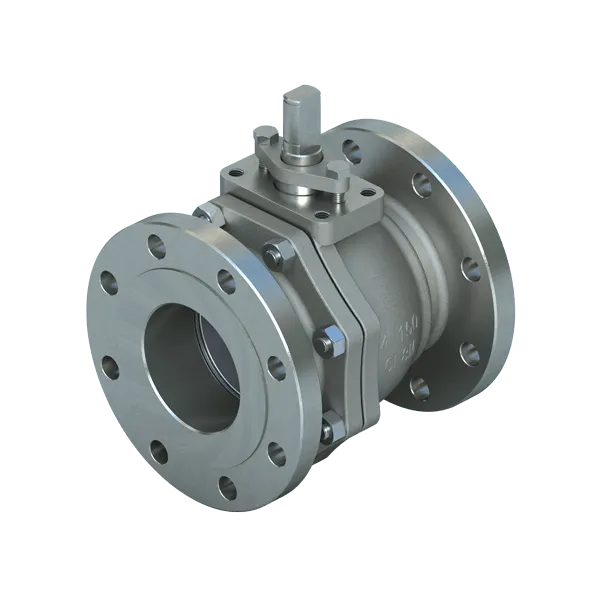

Constructed from investment cast stainless steel, Bray’s MCU is corrosion-resistant and suitable for harsh environments. Available in sizes ranging from 1/4" to 10" (6.35mm to 254mm), Bray MCU’s can be pre-installed at the factory for Triad Series, 7000/8000 Series, S7500/S7700 Series, F15/F30 Series, RF15/RF30 Series, and S85 Series. MCU’s can also be retrofitted through easy field installation.

By utilizing Bray’s MCU, industrial plants can significantly reduce operating costs and unscheduled maintenance events such as Leak Detection and Repair (LDAR) minimizing production downtime and maximizing productivity.

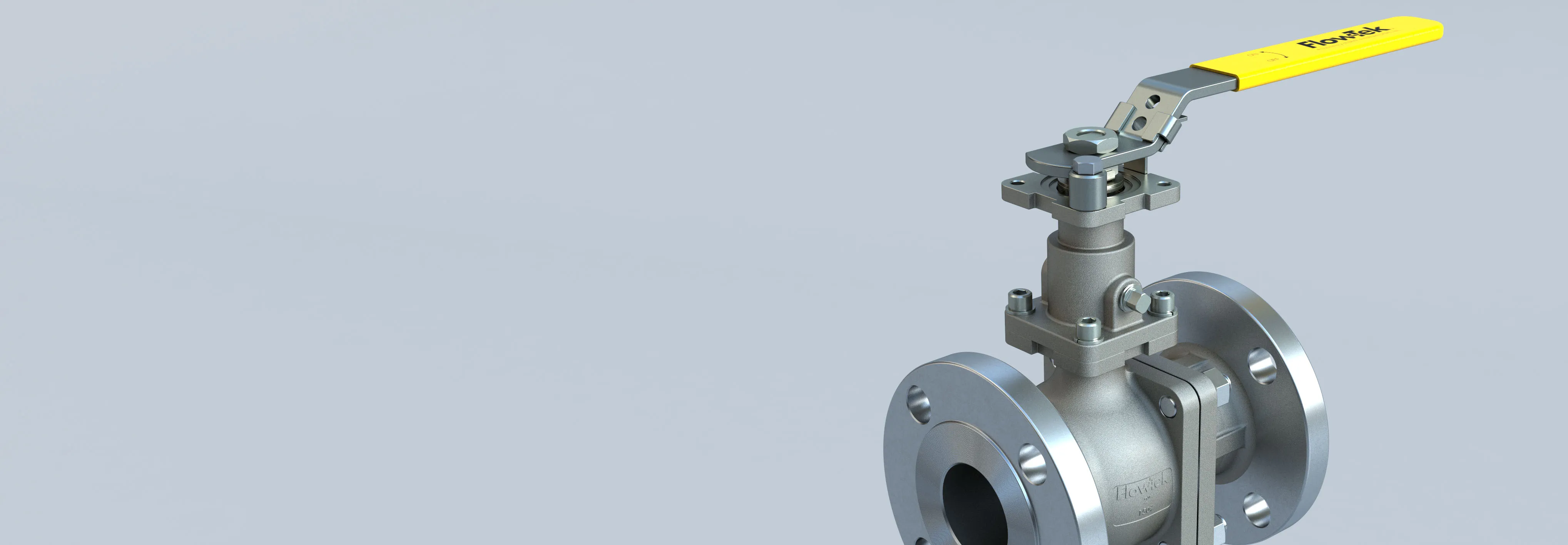

Ball Valve Accessory

Media Containment Unit

Corrosion-Resistant Stainless Steel Ensures Longevity in Demanding Environments

Ideal for Emission Control in Demanding Industrial Environments

API 607: Fire-Safe Design for Industrial Applications

Specifications

Size Range

1/4" to 10" (6.35mm to 254mm)

Accessory Type

Ball Valve Media Containment Unit

Valve Compatibility

Triad Series, Series 7000/8000, Series S7500/S7700,

Series F15/F30, Series RF15/RF30, Series S85

Series F15/F30, Series RF15/RF30, Series S85

applications

Fugitive Emissions, Emission Control, Severe Media, High Cycle, Low & High Temperature, Monitoring, Stem Sealant Device, Steam Extension, Positive Pressure Seal

More Details

Features & Benefits

Tight sealing: flow-tek’s mcu features live-loaded stem sealing with belleville springs that automatically compensate for temperature and pressure fluctuations, maintaining a leak-tight seal for extended cycle life. Multiple tfm v-ring stem packing provides the rigid secondary stem seal. A tfm gasket seals against possible leaks between the unit and valve.

Leak detection: a strategically placed monitoring connection allows the customer/operator to use a pressure gauge or sniffer sensor for early detection of primary stem seal leaks.

Extended temperature range: the additional height of the mcu elevates the packing further away from the valve’s service media and potential temperature extremes. This allows for tight sealing in both high and low temperature applications.

Sealant injection: the mcu can be adapted with a button head check valve to inject sealant for a third seal or for emergency shut-off. An optional second port allows for a combination of monitors, check valve injection or pressure displacement line.

Positive pressure seal: a positive pressure seal can be accomplished by permanently connecting a pneumatic line to the unit to provide a positive pressure supply that barely exceeds the valve line operating pressure. This ensures against any possible valve stem leaks to the atmosphere.

Mounting ease: the housing top pad and stem slot meet flow-tek’s secure mount standards for easy installation of handle or actuator. Installation and maintenance procedures (such as monitoring) can be performed while valve is under full pressure.

Leak detection: a strategically placed monitoring connection allows the customer/operator to use a pressure gauge or sniffer sensor for early detection of primary stem seal leaks.

Extended temperature range: the additional height of the mcu elevates the packing further away from the valve’s service media and potential temperature extremes. This allows for tight sealing in both high and low temperature applications.

Sealant injection: the mcu can be adapted with a button head check valve to inject sealant for a third seal or for emergency shut-off. An optional second port allows for a combination of monitors, check valve injection or pressure displacement line.

Positive pressure seal: a positive pressure seal can be accomplished by permanently connecting a pneumatic line to the unit to provide a positive pressure supply that barely exceeds the valve line operating pressure. This ensures against any possible valve stem leaks to the atmosphere.

Mounting ease: the housing top pad and stem slot meet flow-tek’s secure mount standards for easy installation of handle or actuator. Installation and maintenance procedures (such as monitoring) can be performed while valve is under full pressure.

Our Portfolio

Looking for More Solutions?

Discover Our Range of Products Built for Your Industry's Challenges

Explore More Bray Insights

Learn Even More About How Bray’s Solutions Can Impact Your Business

ISO-Certified Cleanroom Solutions for Superior Valve Integrity

Cleanroom Valve Services

Bray's state-of-the-art cleanroom facilities deliver ISO Class 6 to ISO Class 9 precision cleaning around the globe where valves are cleaned, inspected, bagged & tagged to meet the most stringent global standards, ensuring contamination-free valves.

Discover Our Precision Cleaning Solutions