Ball Valve Accessory

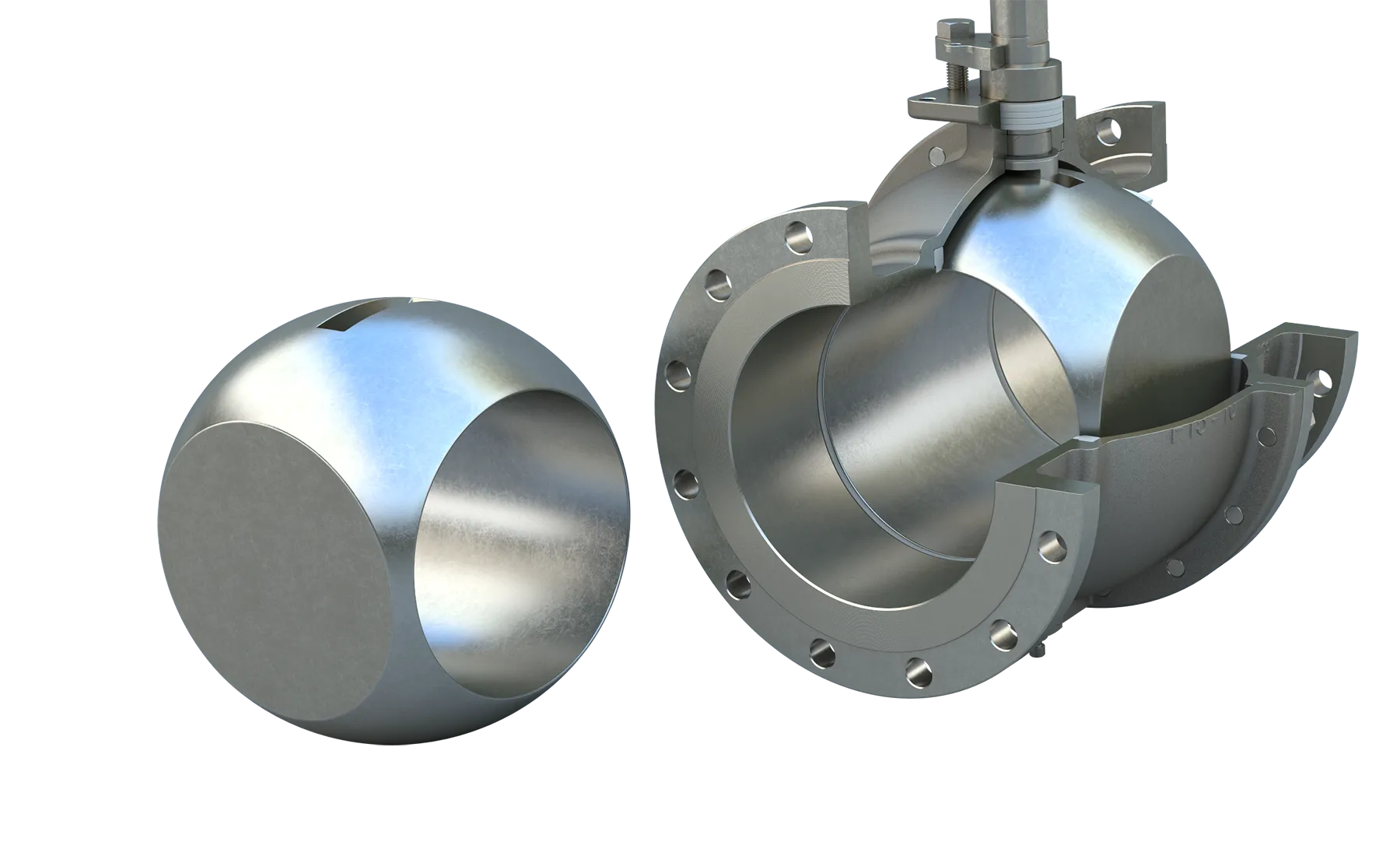

Resolute Ball™

API 641 & ISO 15848-Compliant Resolute Ball™ Valve Design

Compatible with Flanged RF15/RF30 and F15/F30 Models

Reliable Flow Control for Pulp, Mining, and Petrochemical Applications

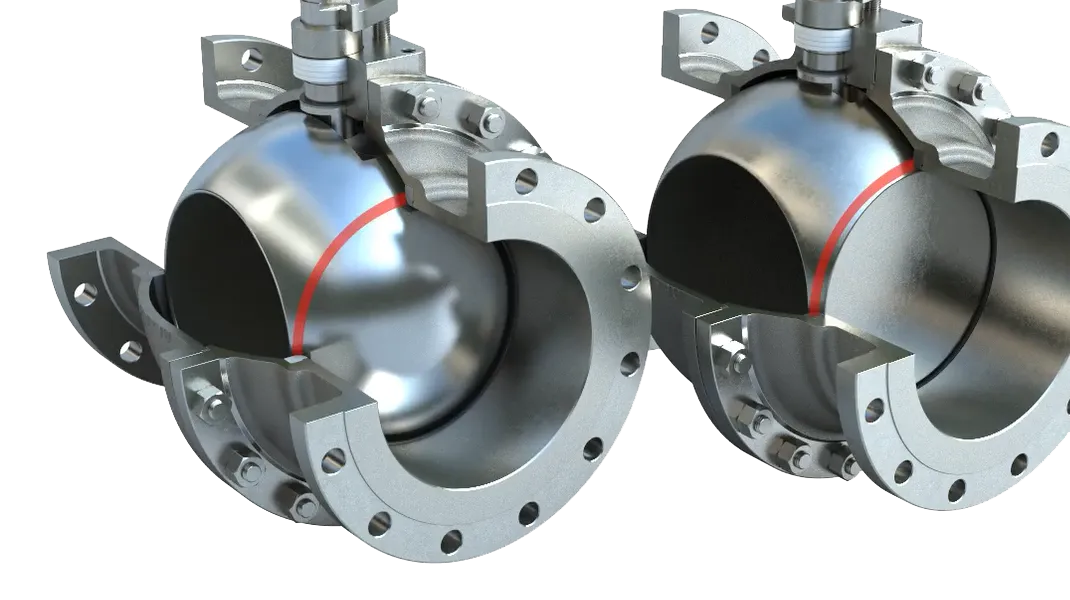

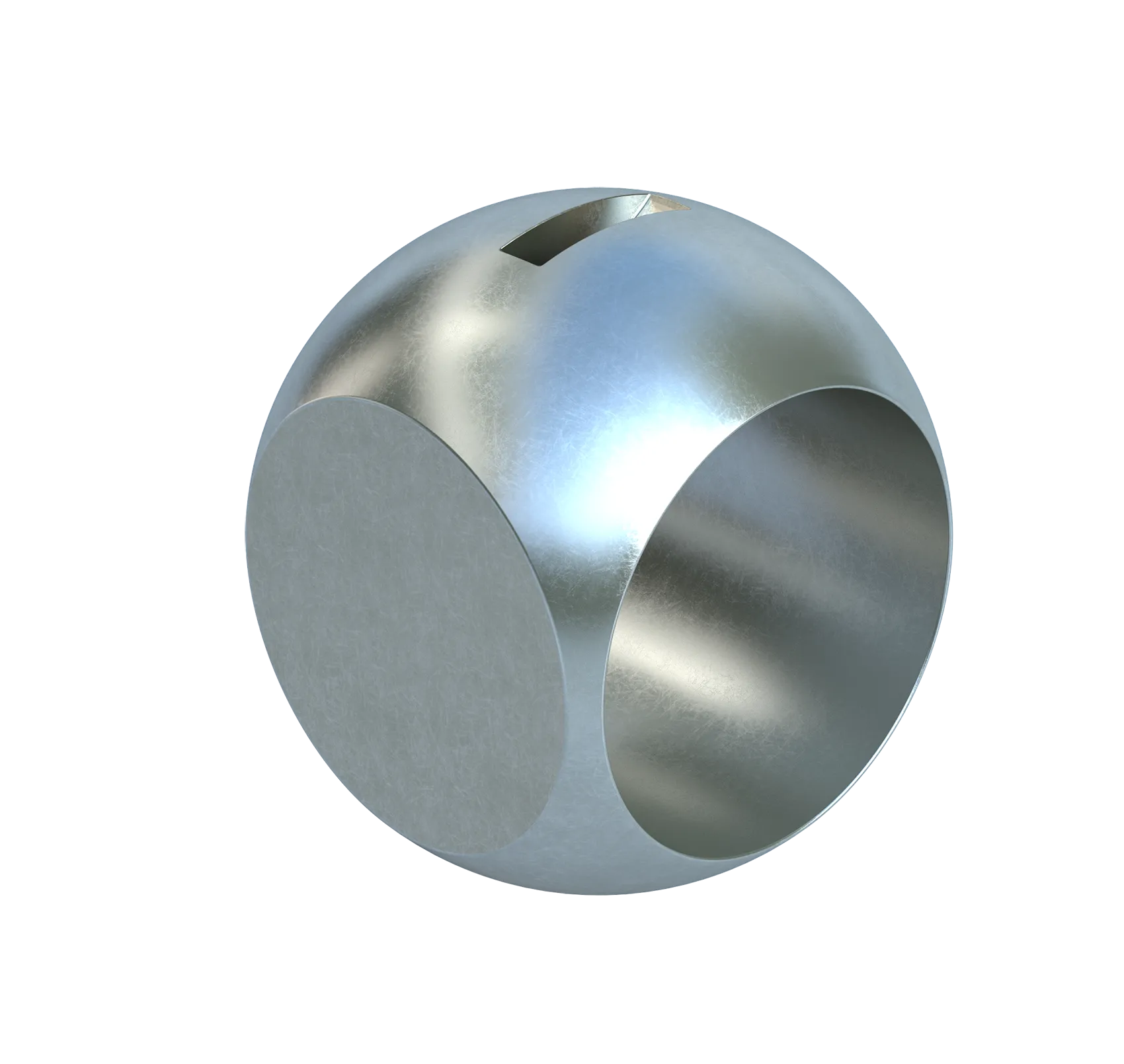

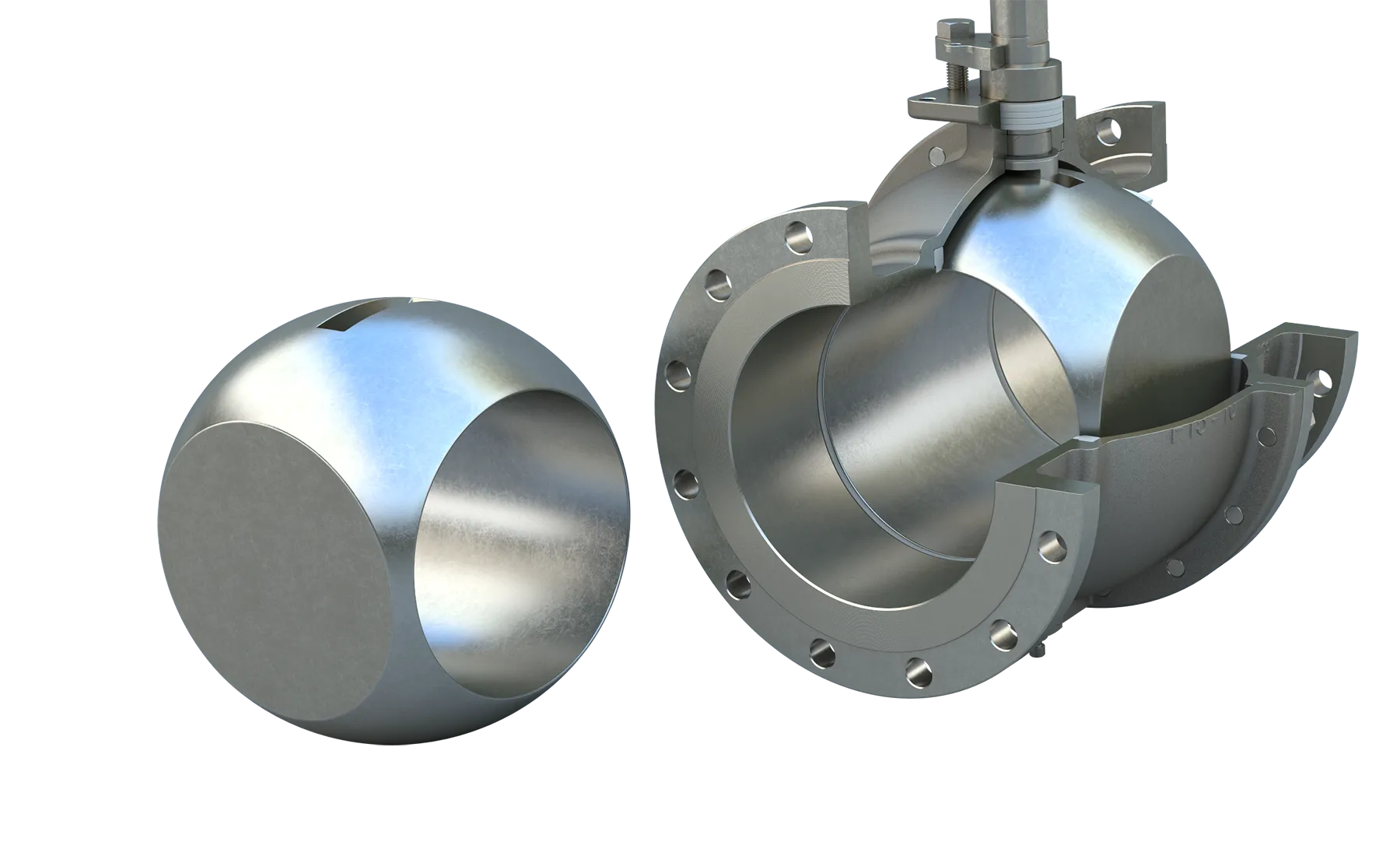

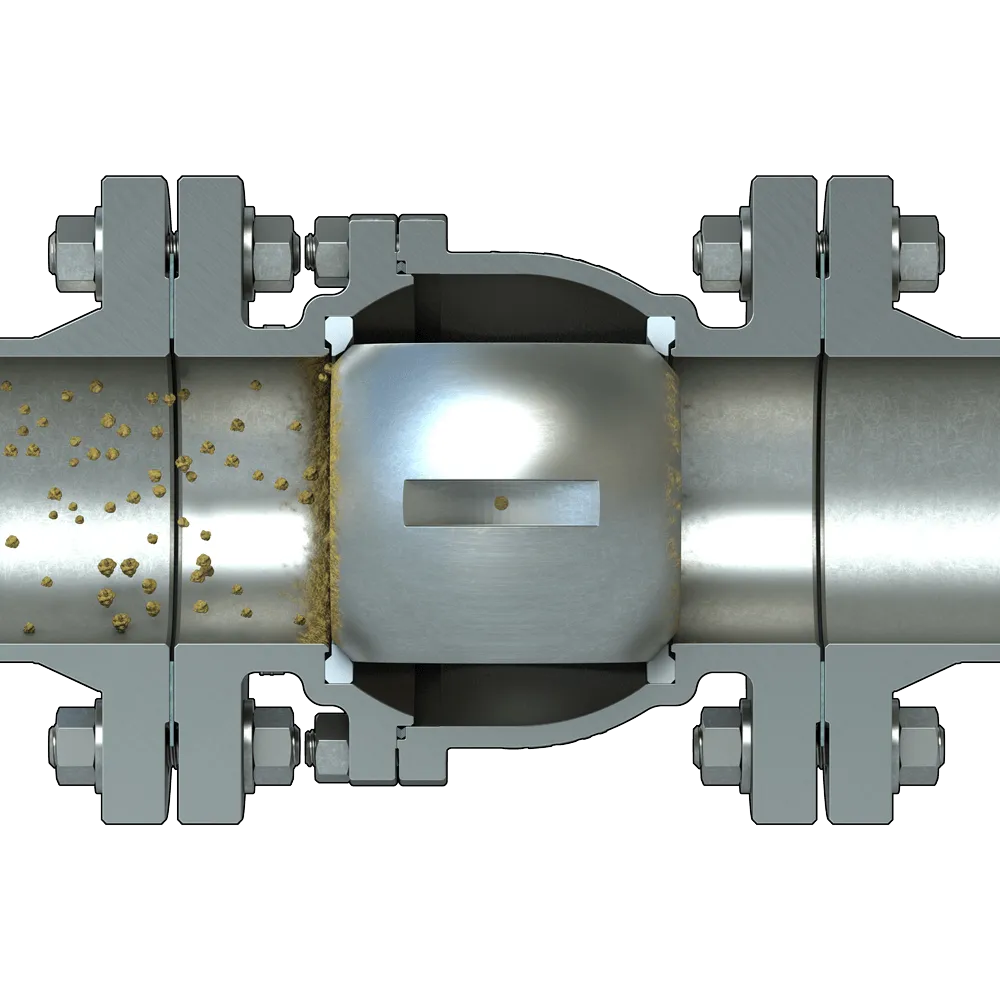

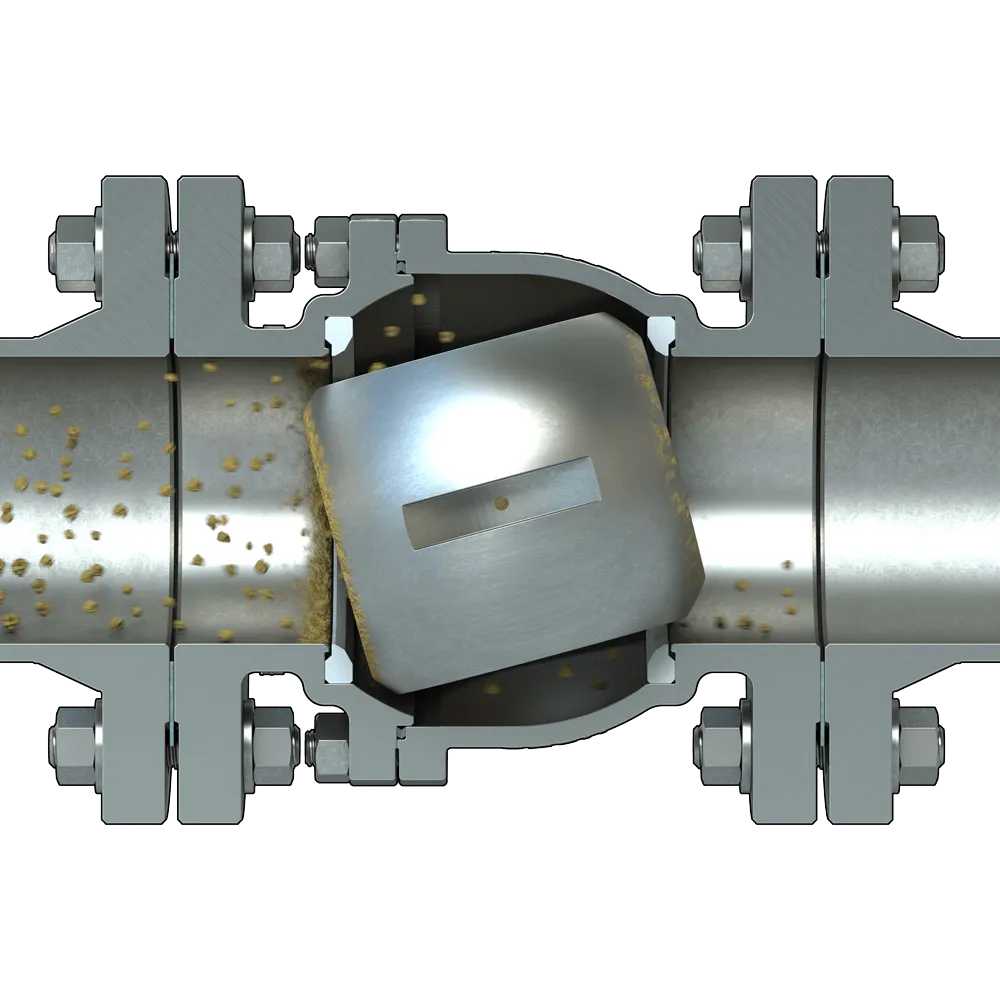

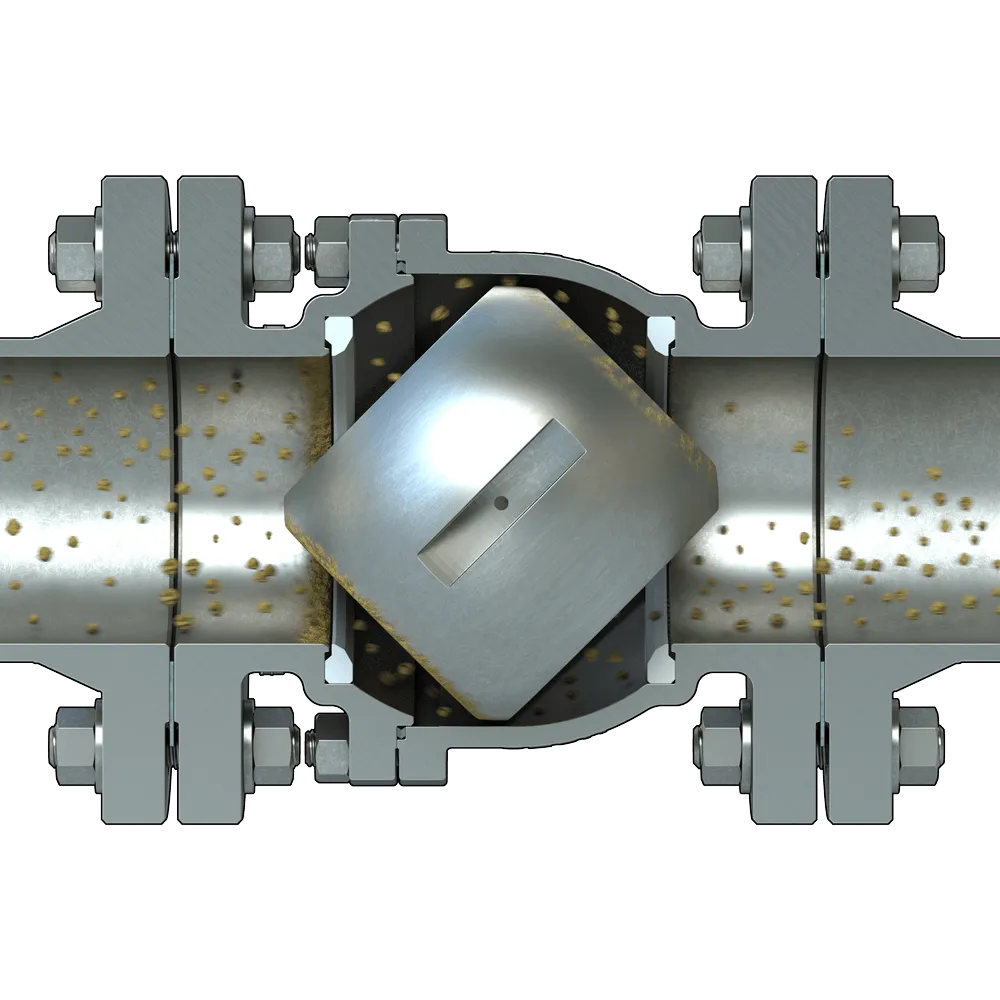

Standard ball valves use a spherical surface that maintains contact between the ball and seat throughout the 90 degree operation. As the valve operates, the scale that has accumulated on the spherical surface of the traditional ball travels across the seat sealing area, resulting in increased torque, scored seal surfaces, and potential failure to operate. The unique, engineered geometry of Bray's Resolute Ball™ Valve has been successful in helping our customers overcome these challenges. As the Resolute Ball™ rotates, media contact with the seat is drastically minimized throughout the quarter-turn operation due to minimal contact between the ball and seat after 10 degrees of rotation. The Resolute Ball™ geometry reduces wear by as much as 70% by enabling accumulated media particles to be flushed past the ball and seats. This unique design provides improved operation, extended service life, reduced valve operating torque, increased reliability, and reduced total cost of ownership for the customer.

The Resolute Ball™ is compatible as a drop-in replacement for multiple standard product lines including the one-piece Flanged ball valve RF15/RF30, two-piece Flanged ball valve F15/F30. Each of these high-performance product lines are field proven with an extensive global install base throughout a wide variety of industries. For additional information, please reference the individual product line brochures.

Specifications

Series RF15/RF30: 1" - 12" (DN 25 - DN 300)

Series RF15/RF30

More Details

Features & Benefits

Resolute Ball™ Design Advantages

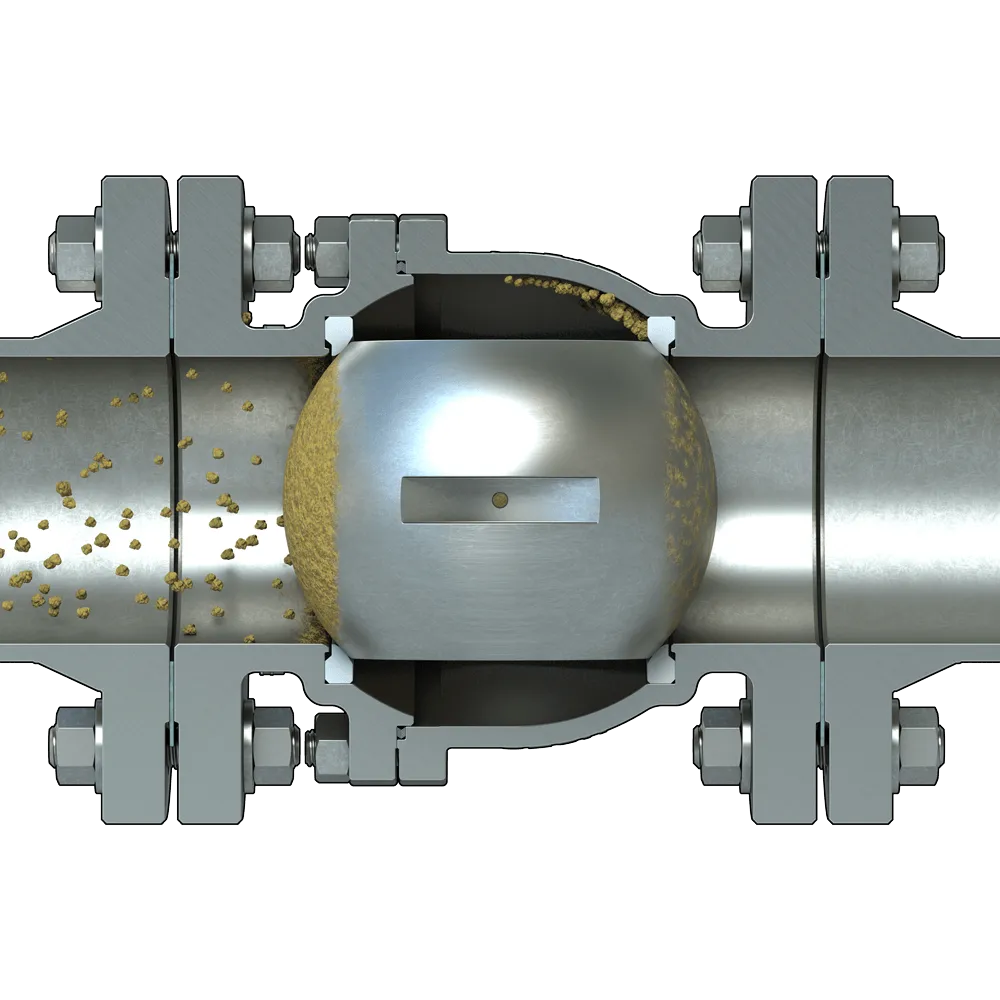

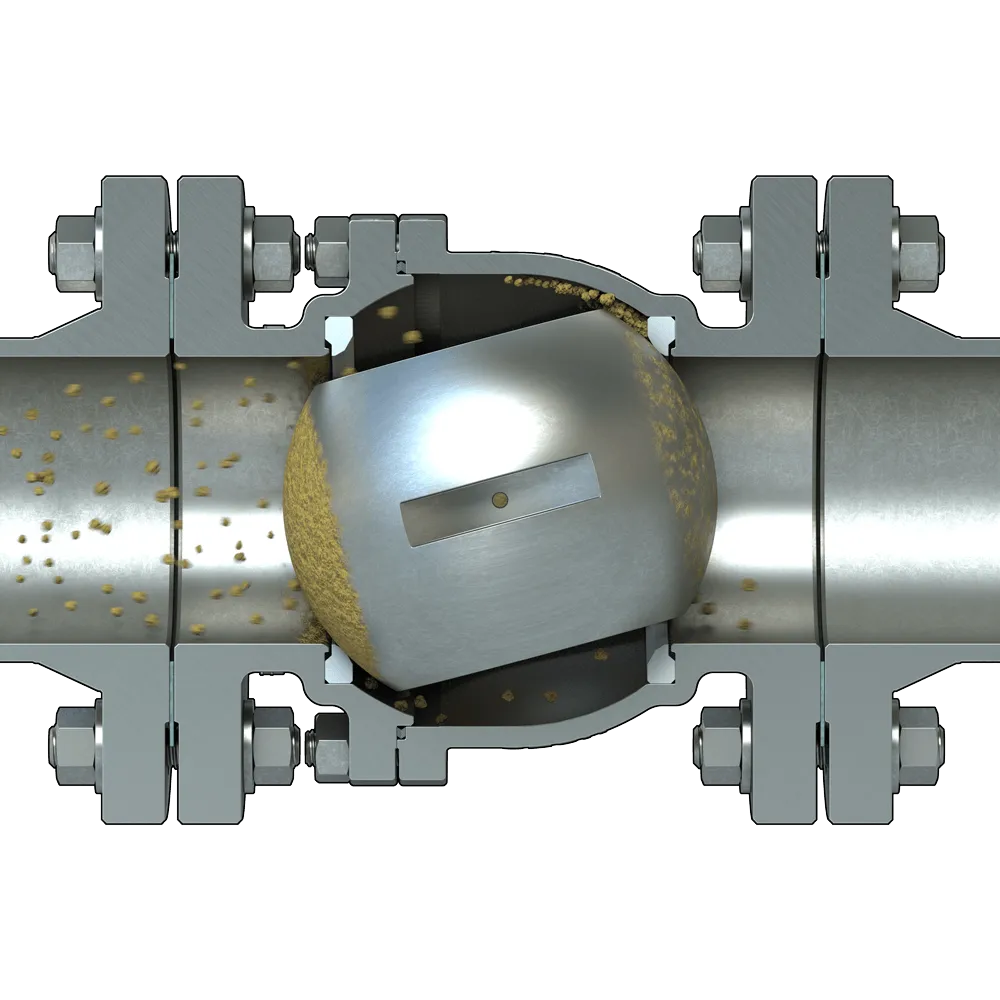

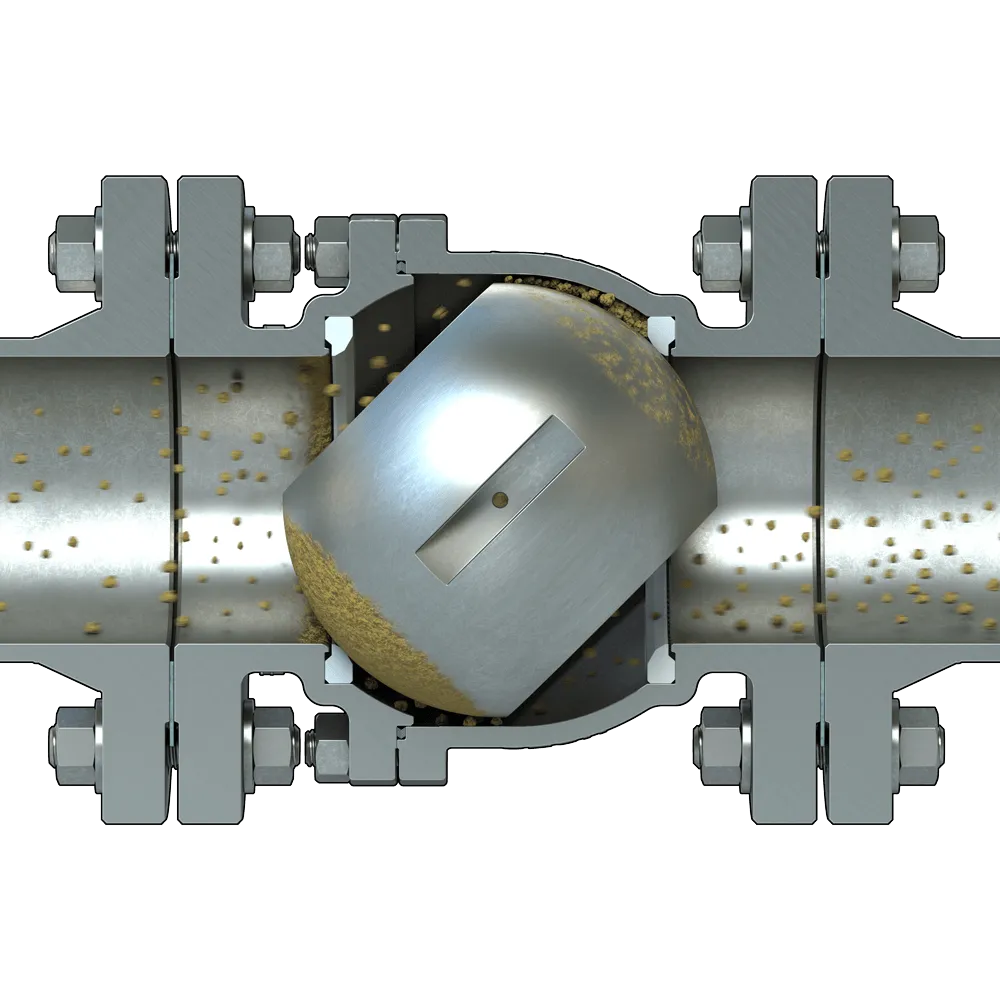

Large spherical surface area allows media buildup on ball surface and downstream ball cavity.

Media buildup leads to seat damage, due to constant contact between ball and seat during full 90° rotation.

High valve torque is required to break significant media buildup. Valve could fail to operate, stem could shear, or seats could leak prematurely.

Resolute Ball™ Design Solutions

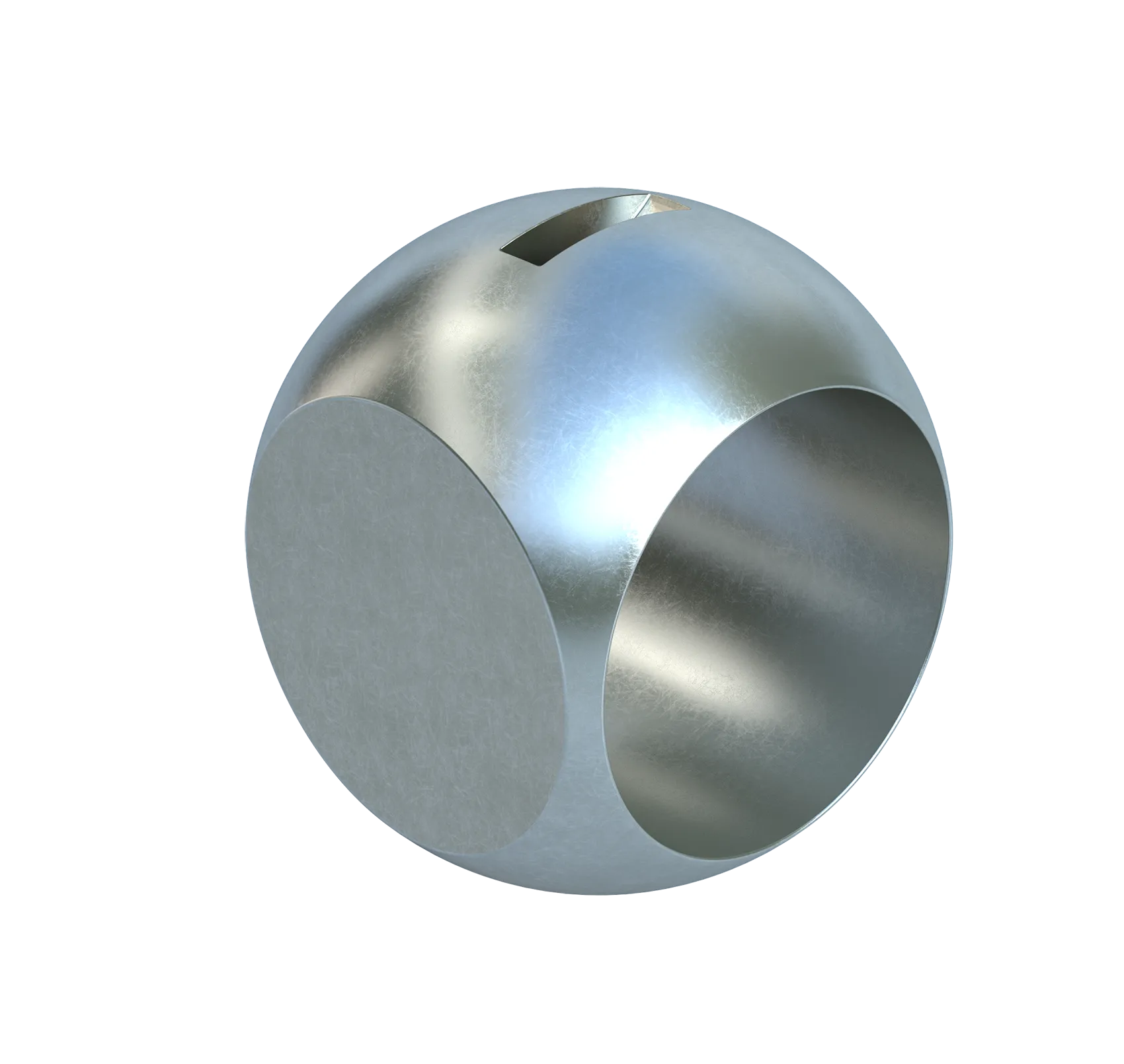

Square ball design minimizes effects of media buildup on ball sealing surface and allows particles to flow through ball cavity.

Seat life is extended, due to reduced media buildup and minimal contact between ball and seat after 10° of rotation.

Low valve torque is required to break minimal buildup. Valve easily operates with standard actuation.

Our Portfolio

Looking for More Solutions?

Discover Our Range of Products Built for Your Industry's Challenges

Explore More Bray Insights

Learn Even More About How Bray’s Solutions Can Impact Your Business

ISO-Certified Cleanroom Solutions for Superior Valve Integrity

Cleanroom Valve Services

Bray's state-of-the-art cleanroom facilities deliver ISO Class 6 to ISO Class 9 precision cleaning around the globe where valves are cleaned, inspected, bagged & tagged to meet the most stringent global standards, ensuring contamination-free valves.

Discover Our Precision Cleaning Solutions