More Details

Features & Benefits

-

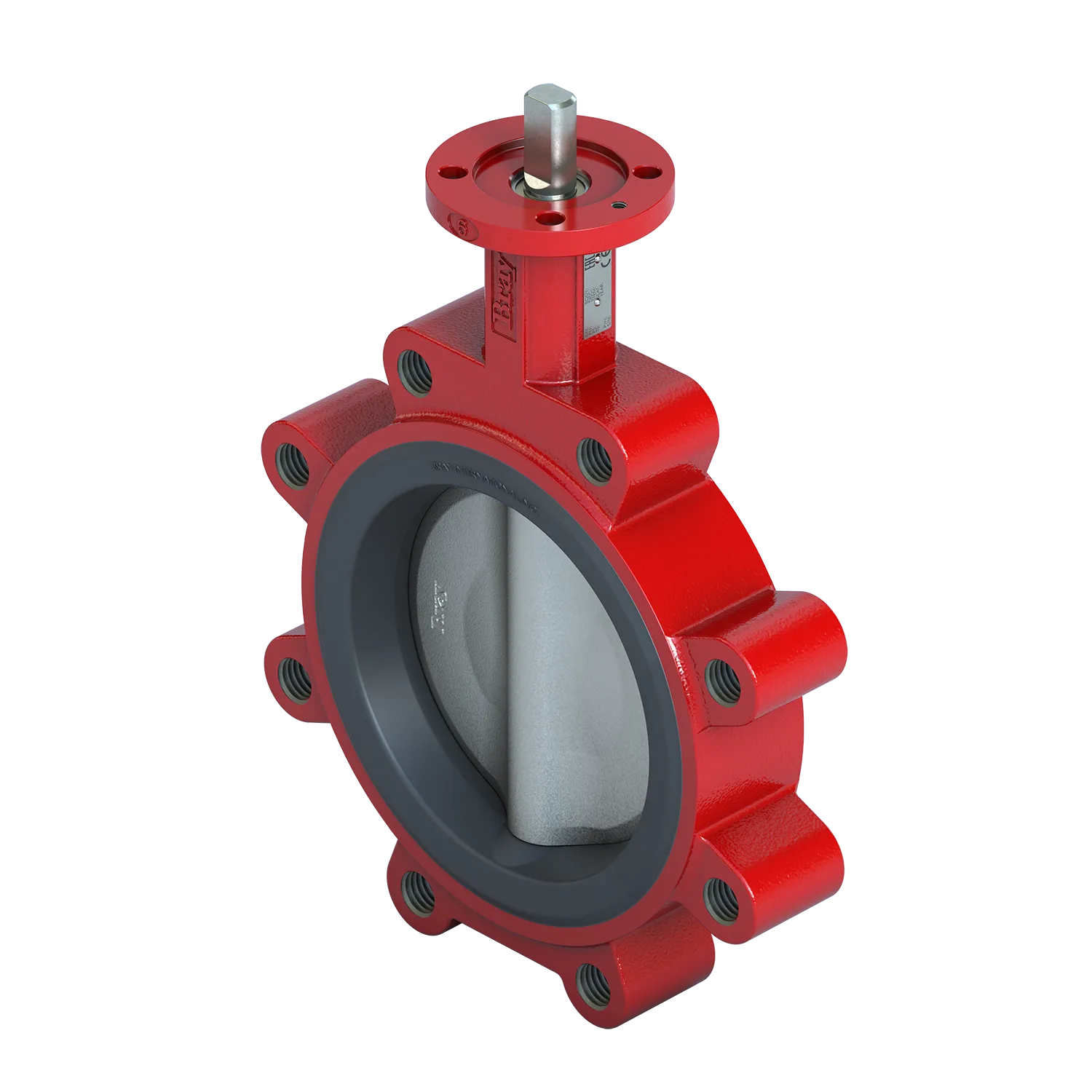

A. Digital Tag

Each valve is uniquely and easily identifiable by simply scanning the QR Code on the product identification tag in accordance to IEC 61406.

-

B. Electrostatic discharge through antistatic design

Electrostatic discharge through antistatic design (Ground washer and Top flange drilling).

-

C. Stem Design

The high-strength stem design combine blowout-proof functionality for safe operation and excpetional service life.

-

D. Stem Bushing

Non-corrosive, heavy duty acetal bushing absorbs actuator side thrust.

-

E. Robust Flange Sealing

Tear-dropped shaped seat face enables tight sealing with a wide variety of industrial flanges.

-

F. Molded-in Seat

Tightly controlled molding process produces accurate and repeatable dimensions, which leads to consistently lower torques over the valve’s lifetime.

-

G. Precision Profiled Disc Sealing Edge

Extends the valve life by reducing seat wear.

-

H. Upper and Lower Stem Bearings

Reduce operating torque and increase reliability in high cycle applications.

-

I. End of Line Capability

Lug style valve allows for sealing at full rated pressure even when the downstream flange is removed.

Explore More Bray Insights

Learn Even More About How Bray’s Solutions Can Impact Your Business