More Details

Features & Benefits

-

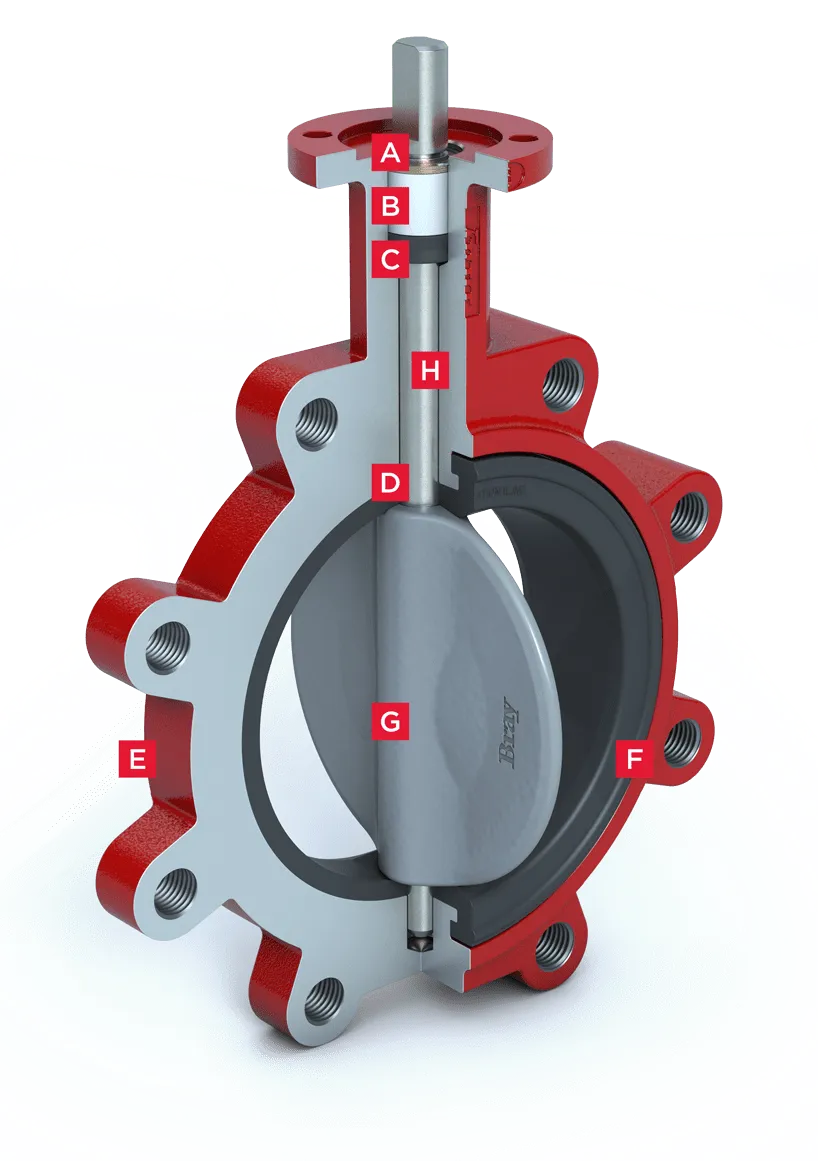

A. Stem Retaining Assembly

The stem is retained in the body by means of a unique stainless steel Spirolox® retaining ring, a thrust washer and two C-rings, manufactured from brass as standard, stainless steel upon request.

-

B. Stem Bushing

Non-corrosive, heavy duty acetal bushing absorbs actuator side thrust.

-

C. Stem Seal

Double “U” cup seal design is self-adjusting and gives positive sealing in both directions.

-

D. Primary And Secondary Seals

These seals prevent line media from coming in contact with the stem or body. The primary seal is an interference fit of the molded seat flat with the disc hub. The secondary seal is created because the stem diameter is greater than the diameter of the seat stem hole.

-

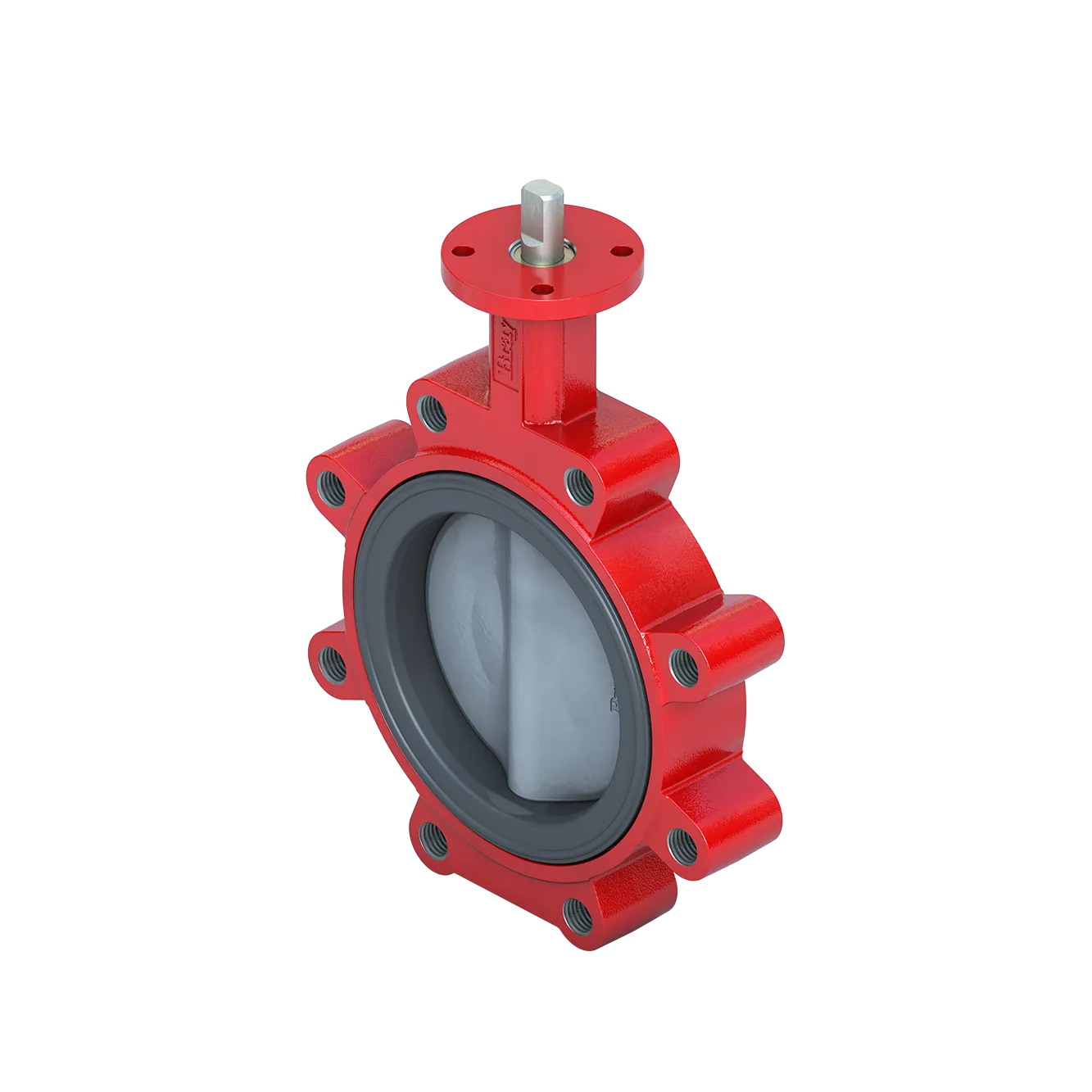

E. Body

One piece lug style. Polyester coating for excellent corrosion resistance. Nylon 11 coating is available as an option.

-

F. Seat

Bray’s tongue and groove seat design provides complete isolation of flowing media from the body. The seat also features a molded o-ring which eliminates the use of flange gaskets.

-

G. Disc

Casting is spherically machined and hand polished to provide a bubble tight shutoff, with minimum torque, and longer seat life. Bray’s resilient Nylon 11 coating comes as standard.

-

H. Stem

Precision double “D” disc to stem connection drives the disc without the need for screws or pins. The close tolerance, double “D” connection that drives the valve disc is an exclusive feature of the Bray valve. Disassembly of the Bray stem is just a matter of pulling the stem out of the disc.

Explore More Bray Insights

Learn Even More About How Bray’s Solutions Can Impact Your Business