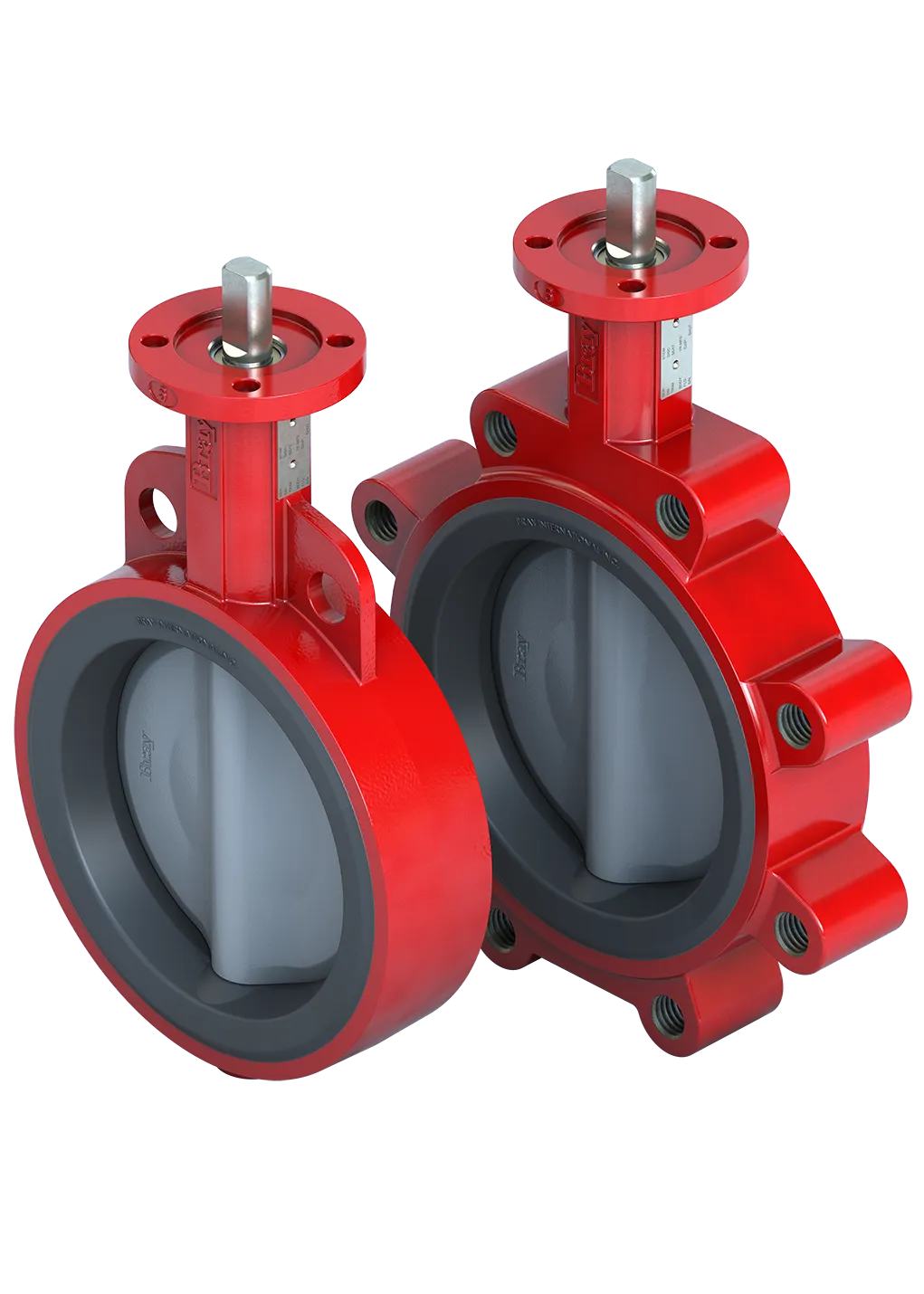

The Bray Series 3W/3L is a resilient seated butterfly valve engineered for automation-ready performance in high-cycle applications. Its one-piece body with a molded-in elastomer seat ensures pressure stability and long-term bubble-tight shutoff, even in demanding line conditions.

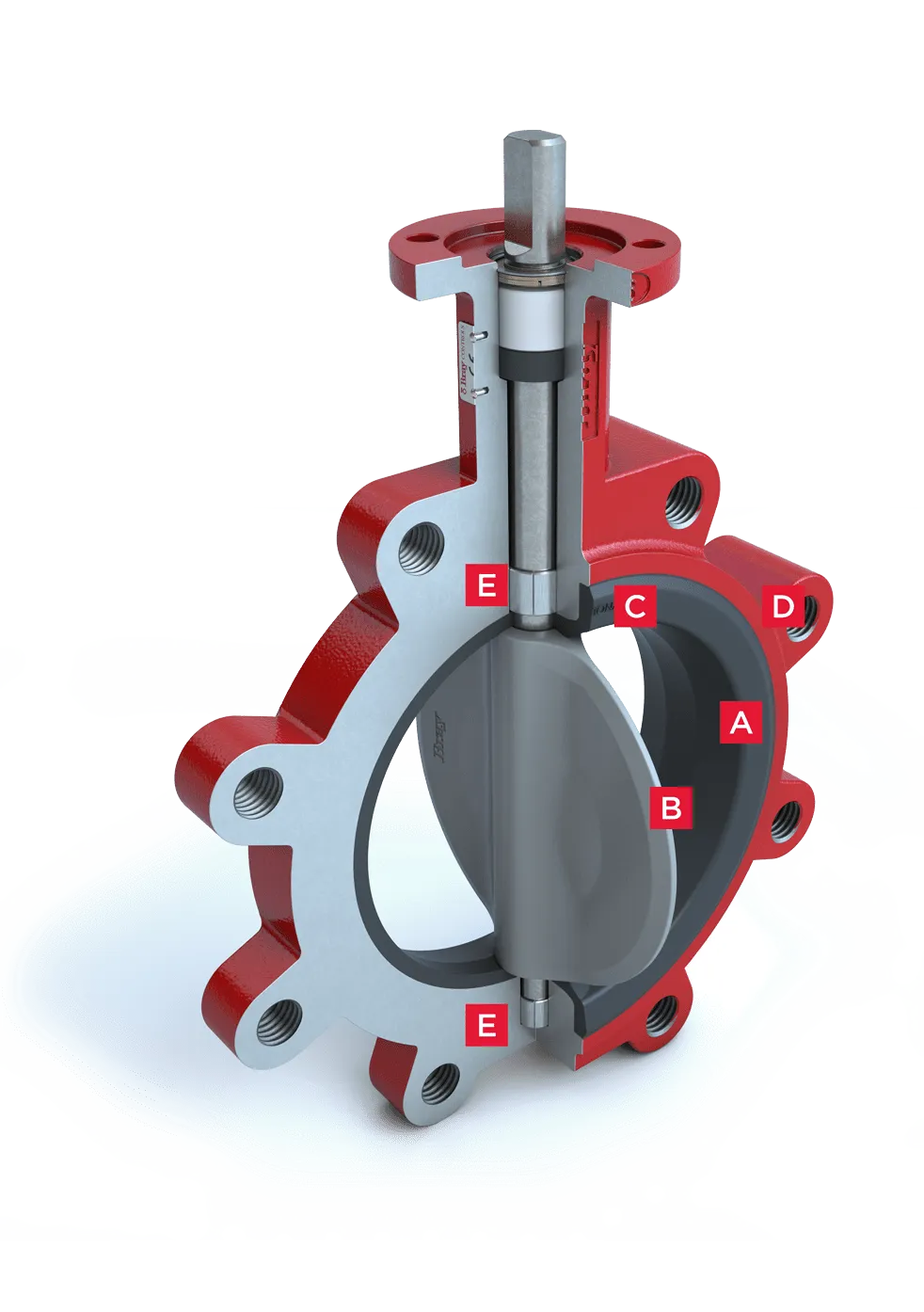

The 3W/3L valve features:

- ISO 5211 top flange for direct actuator mounting.

- Disc-to-stem design that reduces hysteresis and improves control accuracy.

- Tear-drop flange sealing for consistent, secure fit across flange types.

- End-of-line capability in lug body designs for added flexibility.

With a temperature range of -20°F to 250°F (-29°C to 121°C) and compatibility with Buna-N and EPDM elastomers, stainless steel or nylon-coated discs, the 3W/3L is trusted in HVAC, desalination, steam, sour gas, and vacuum services. Backed by Bray’s global support and automation solutions, it provides cost-effective and reliable isolation for industries worldwide.