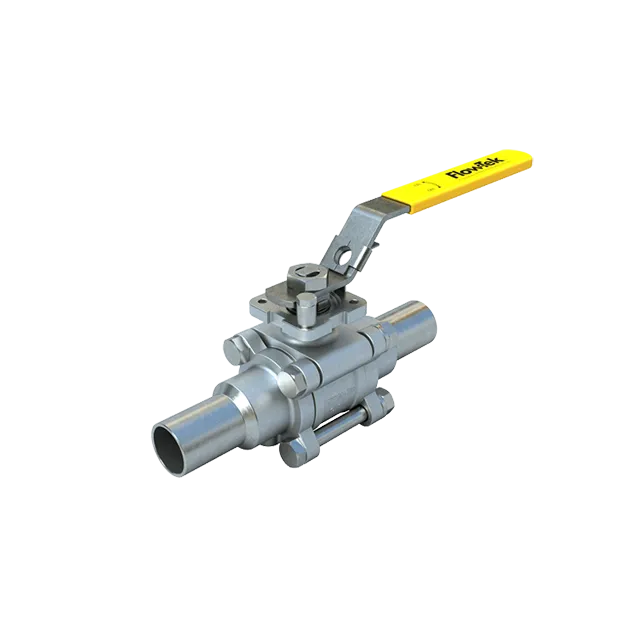

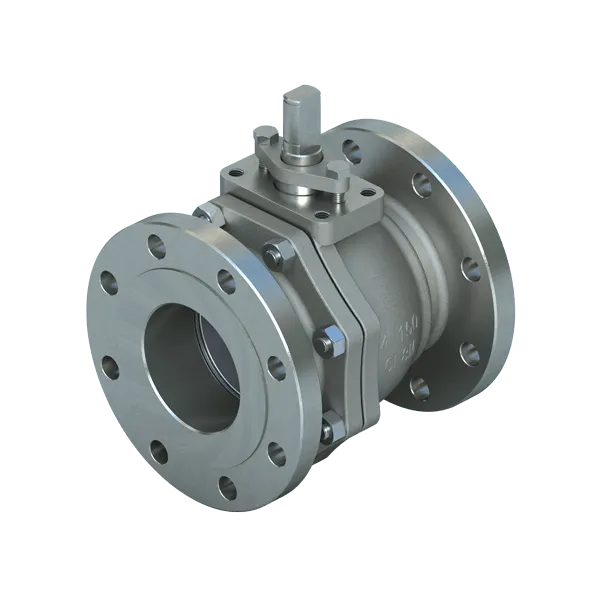

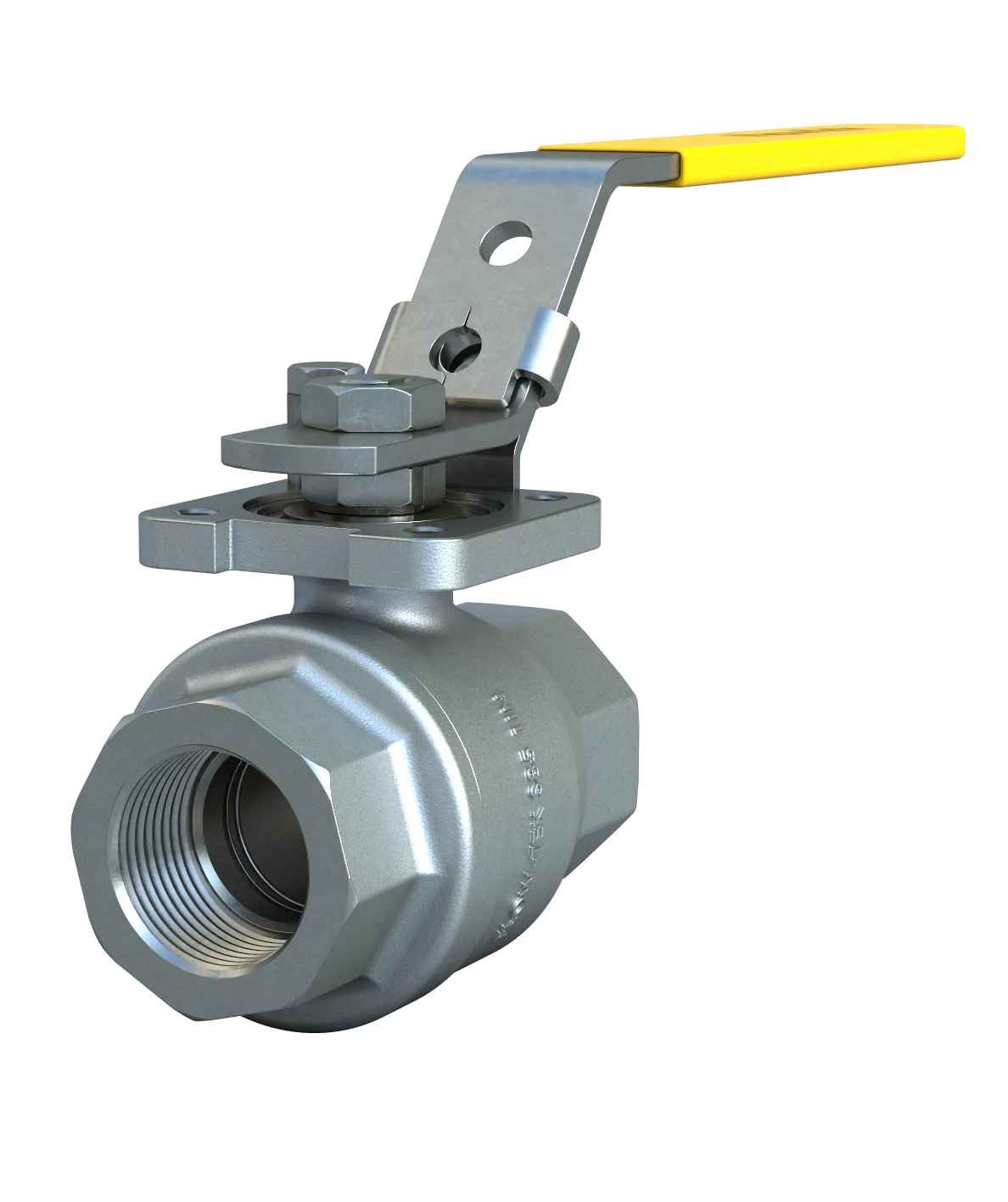

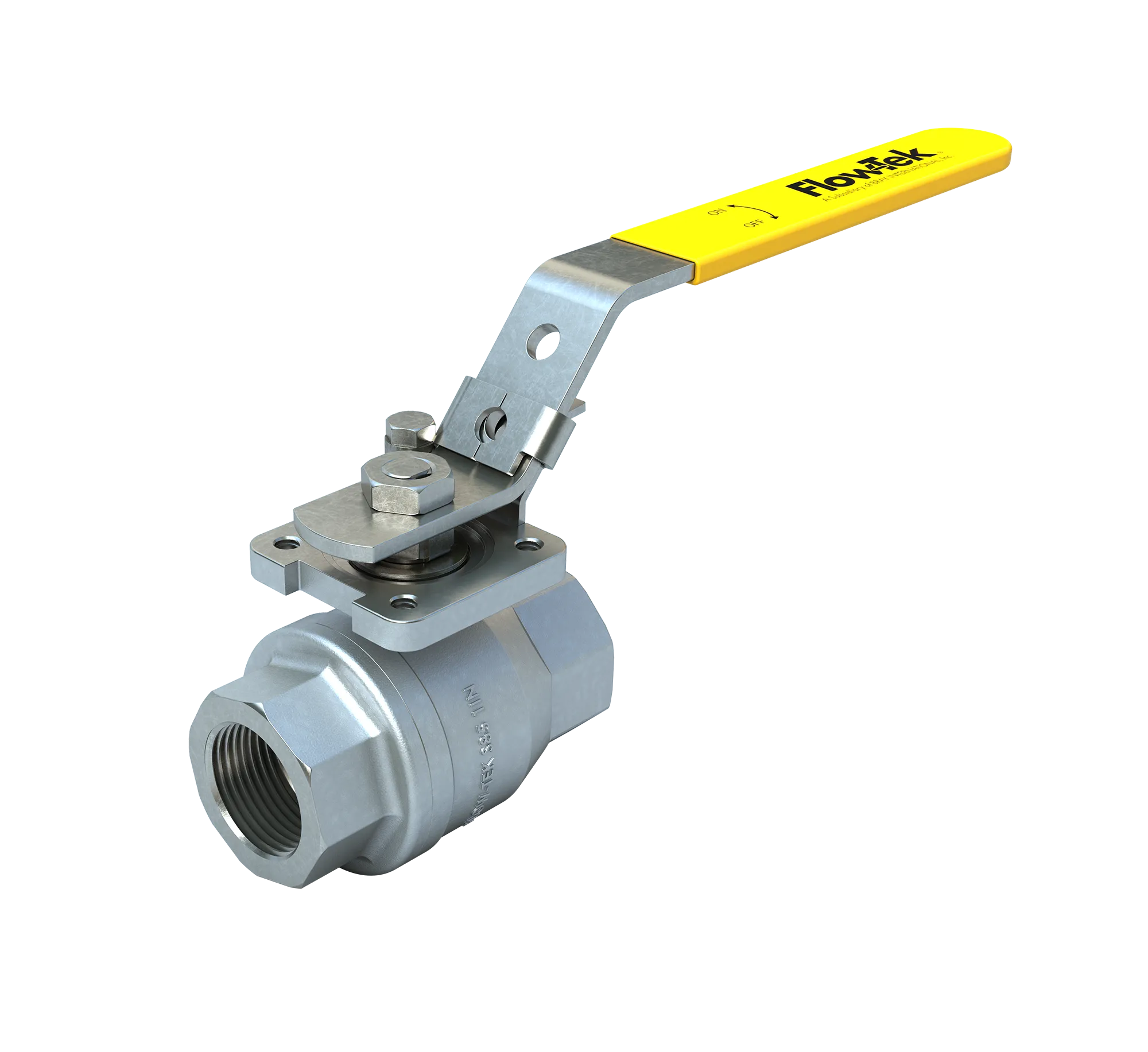

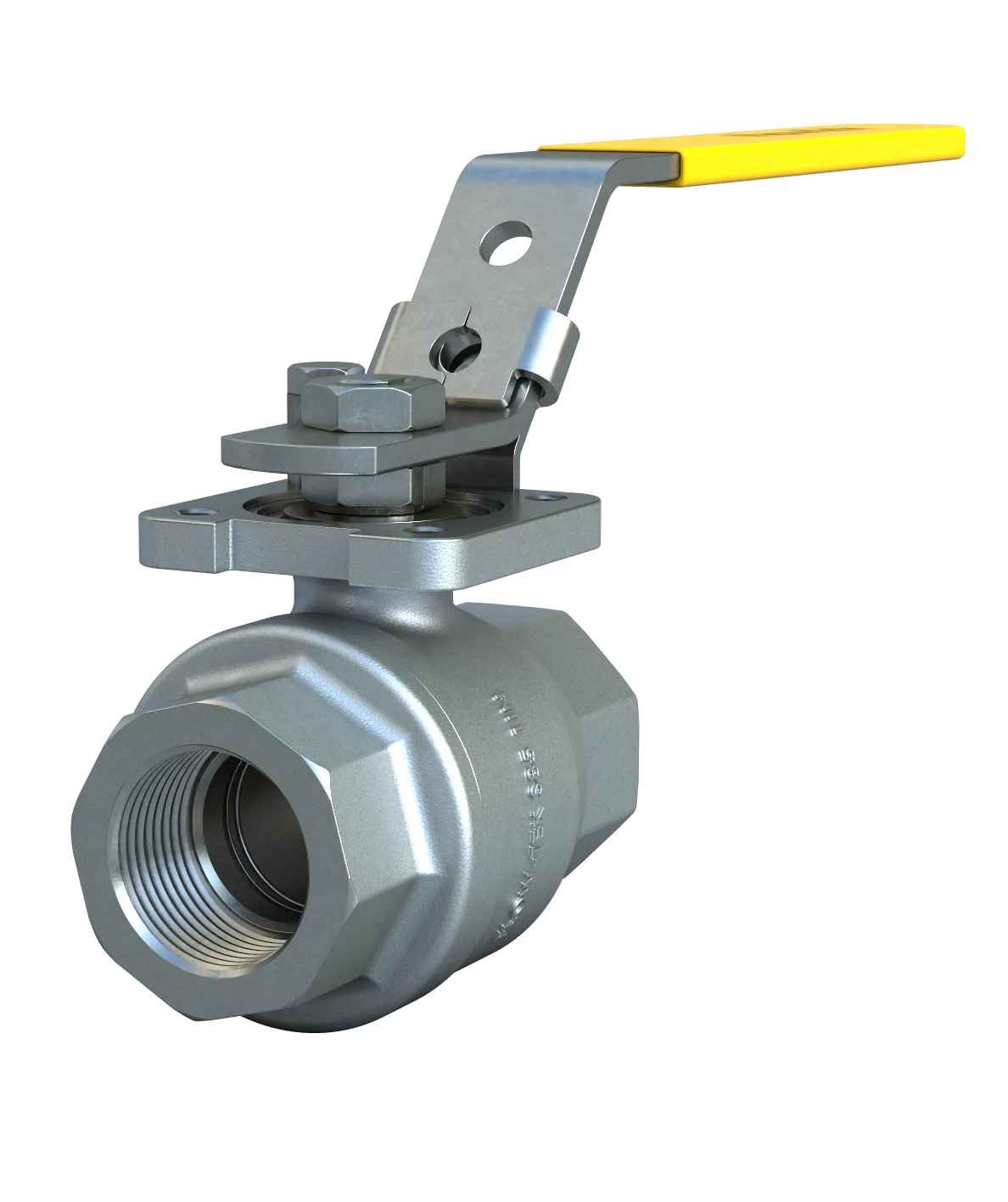

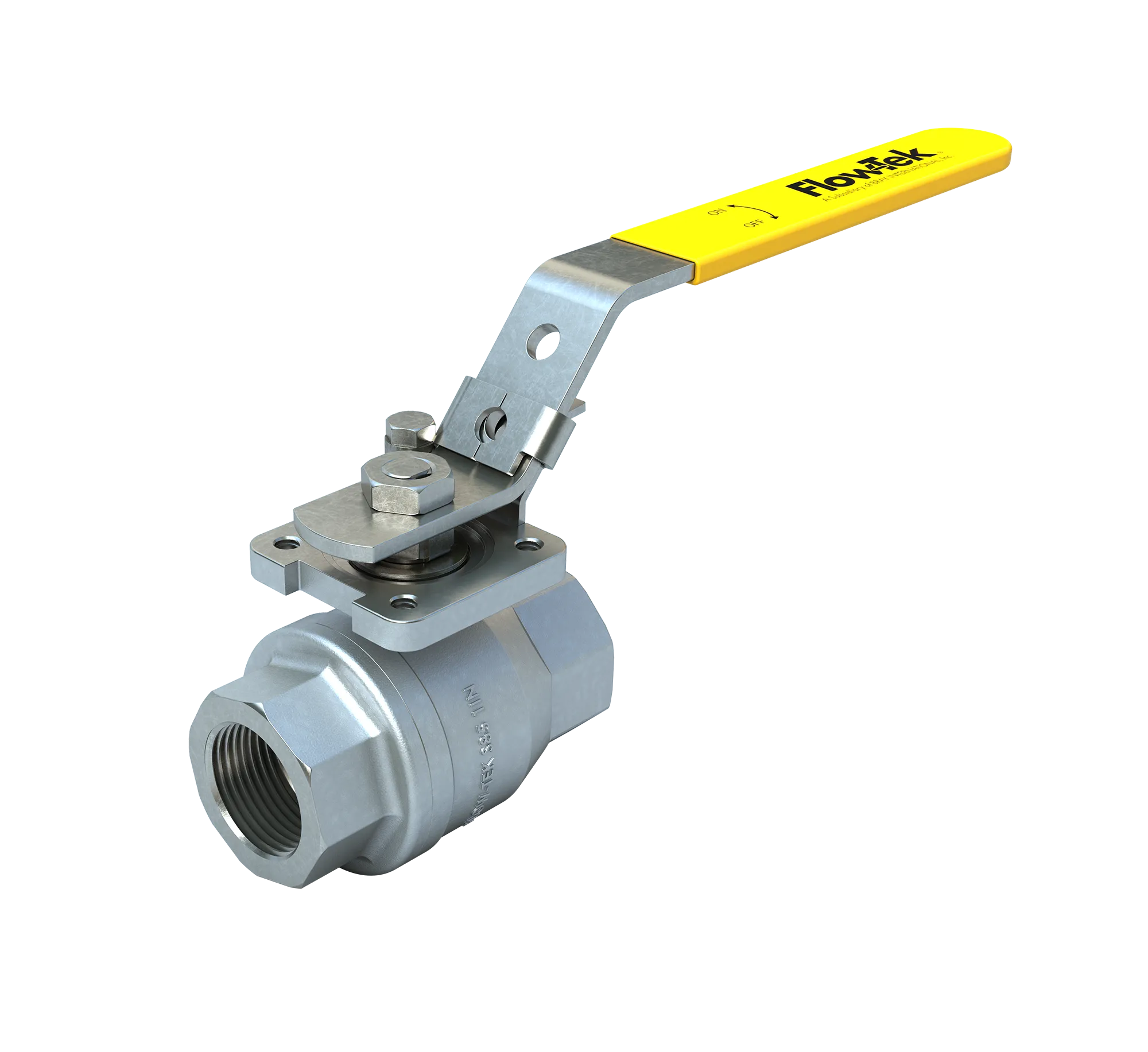

Threaded Ball Valve

Series S85

Engineered for Safety With Anti-Static Devices and Blowout-Proof Stem Design

NSF and NACE Certified Valves

Reliable Two-Piece Ball Valves for Oil, Gas, and Drinking Water Applications

Bray Series 85 Threaded Ball Valves are engineered to simplify automation with our modular line of actuators. Featuring an Integrally Cast ISO 5211 secure mounting pad and an NPT threaded closure, Series 85 threaded full-port ball valves are an outstanding solution for automated valves in a wide variety of industrial automated ball valve applications requiring zero-leakage and in a two-piece ball valve with threaded NPT end connections.

Series 85 Ball Valves feature a wide variety of certifications for sour gas applications in oil & gas under NACE MR0175, drinking water under NSF-61/372 while also meeting the requirements of the U.S. EPA’s Safe Drinking Water Act (SDWA), and hazardous location service under ATEX for explosive environments, as well as PED/PE(S)R Pressure Equipment Directive requirements for Europe and the UK, and CRN certification for Canada, as well as Safety Integrity Level (SIL) rating for safety systems.

Key features of Series 85 ball valves include a bottom entry, blowout-proof stem that prevents stem ejection under line pressure and a live-loaded, self-adjusting stem seal that automatically compensates for wear and temperature swings, ensuring a tight seal, reduced maintenance and consistent performance over time. S85 also incorporates an anti-static device, preventing static electricity buildup that could pose risks in hazardous or explosive industrial environments. Other features of the Series S85 threaded ball valve includes replaceable seats and seals, for easy maintenance and extended service life.

All series 85 threaded two-piece ball valves are tested in accordance to MSS-SP-72 and feature an industry-leading warranty, making Bray Series 85 ball valves ideal for valve automation applications across a wide variety of industries.

Series 85 Ball Valves feature a wide variety of certifications for sour gas applications in oil & gas under NACE MR0175, drinking water under NSF-61/372 while also meeting the requirements of the U.S. EPA’s Safe Drinking Water Act (SDWA), and hazardous location service under ATEX for explosive environments, as well as PED/PE(S)R Pressure Equipment Directive requirements for Europe and the UK, and CRN certification for Canada, as well as Safety Integrity Level (SIL) rating for safety systems.

Key features of Series 85 ball valves include a bottom entry, blowout-proof stem that prevents stem ejection under line pressure and a live-loaded, self-adjusting stem seal that automatically compensates for wear and temperature swings, ensuring a tight seal, reduced maintenance and consistent performance over time. S85 also incorporates an anti-static device, preventing static electricity buildup that could pose risks in hazardous or explosive industrial environments. Other features of the Series S85 threaded ball valve includes replaceable seats and seals, for easy maintenance and extended service life.

All series 85 threaded two-piece ball valves are tested in accordance to MSS-SP-72 and feature an industry-leading warranty, making Bray Series 85 ball valves ideal for valve automation applications across a wide variety of industries.

Specifications

Size Range

NPS ½ to 3 / DN 15 to 80

Body Materials

ASTM A351 CF8M

Temperature Range

-50°F to 450°F (-46°C to 232°C)

Stem Materials

ASTM A479 Type 316

Maximum Allowable Operating Pressure

1000 psi WOG (69 Bar)

Seat Materials

RPTFE

Shutoff Rating

Zero Leakage

Ball Materials

ASTM A351 CF8M

Body Style

Two Piece

Design Standard

ASME B16.34

End Connections

Threaded: NPT

Testing Standard

MSS SP72, MSS SP110

Certifications

ATEX, CRN, NACE MR0175, NSF 61/372, PED, PE(S)R, SIL

Ports

Full Port

Face to Face

Manufacturers Standard

applications

General Service, Air, Water, Oil & Gas

Downloads

Technical Bulletin

Ball Valves Actuator Selection Guide

Download

English

IOM Manual

Threaded Ball Valves Series S85

Download

English

Selection Guide

Threaded Series Ball Valve Part Numbering

Download

English

Product Brochure

Threaded Ball Valves Series S85

Download

English

Safety Manual

Series 85 Quarter Turn Flanged Floating Ball Valves

Download

English

Certification

NSF/ANSI/CAN 61 & 372 Certified Ball Valves

Download

English

Sales Data Sheet

Flow-Tek® Series 85 2 Piece Threaded Full Port Ball Valves

Download

English

Our Portfolio

Looking for More Solutions?

Discover Our Range of Products Built for Your Industry's Challenges

Explore More Bray Insights

Learn Even More About How Bray’s Solutions Can Impact Your Business

ISO-Certified Cleanroom Solutions for Superior Valve Integrity

Cleanroom Valve Services

Bray's state-of-the-art cleanroom facilities deliver ISO Class 6 to ISO Class 9 precision cleaning around the globe where valves are cleaned, inspected, bagged & tagged to meet the most stringent global standards, ensuring contamination-free valves.

Discover Our Precision Cleaning Solutions