More Details

Features & Benefits

- Designed for easy, quick conversion between manual and pneumatic actuation. Featuring a lubricant injection port for continuous, smooth operation with minimal maintenance.

- Clevis design and horizontal bolting stabilizes gate ensuring proper alignment.

- Standard multi-layer square packing provides exceptional gland sealing.

- Optional energized quad seal packing for enhanced gland sealing.

- Wiper/Anti Extrusion Ring minimizes the gap between the body and the gate

- Unrestricted flow path with minimal pressure drop achieved through full port valve design

- Deflection resistant gate design ensures consistent alignment for industry leading durability

- Replaceable flexible wire reinforced elastomer seat ensures bidirectional zero leakage shutoff

-

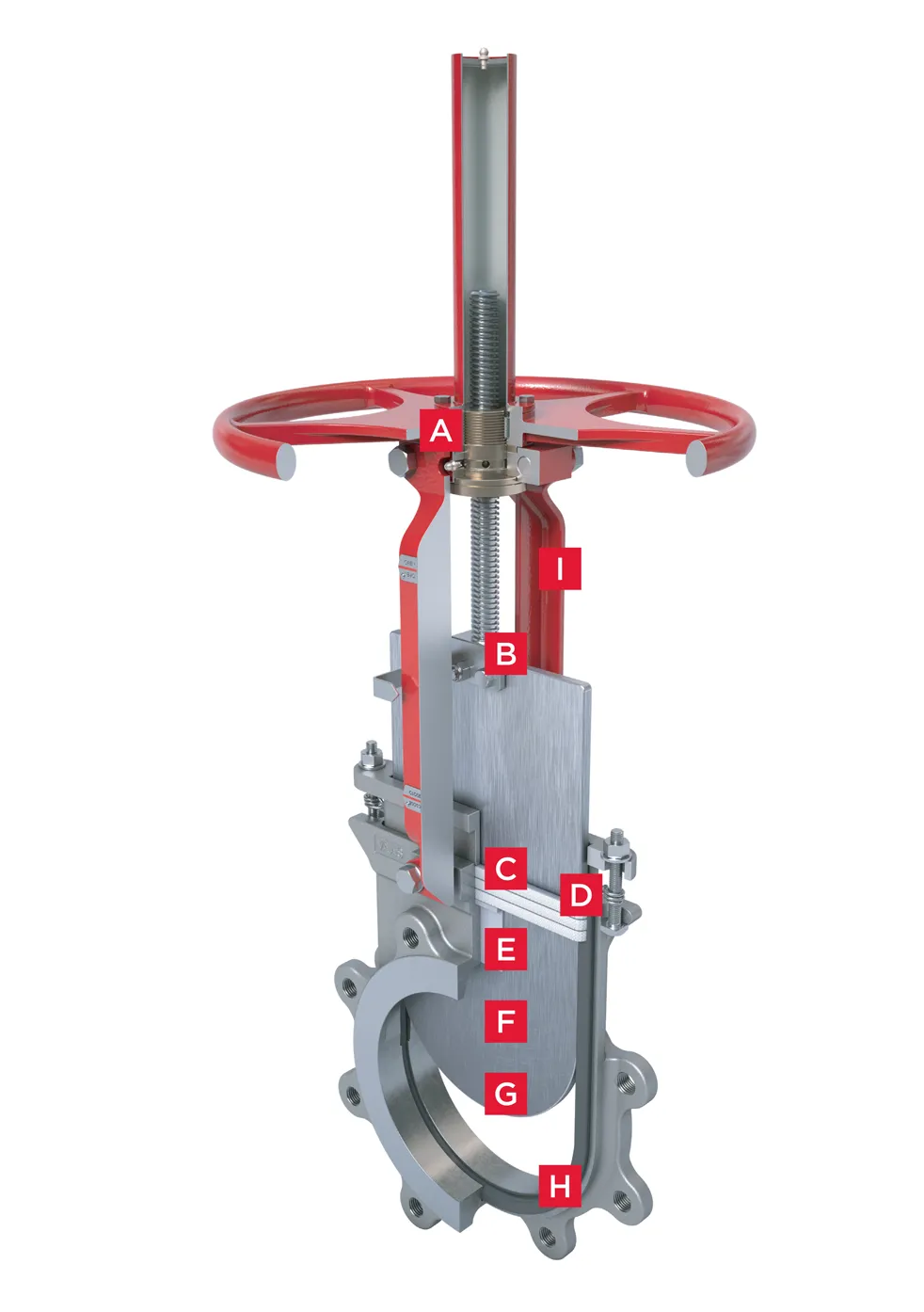

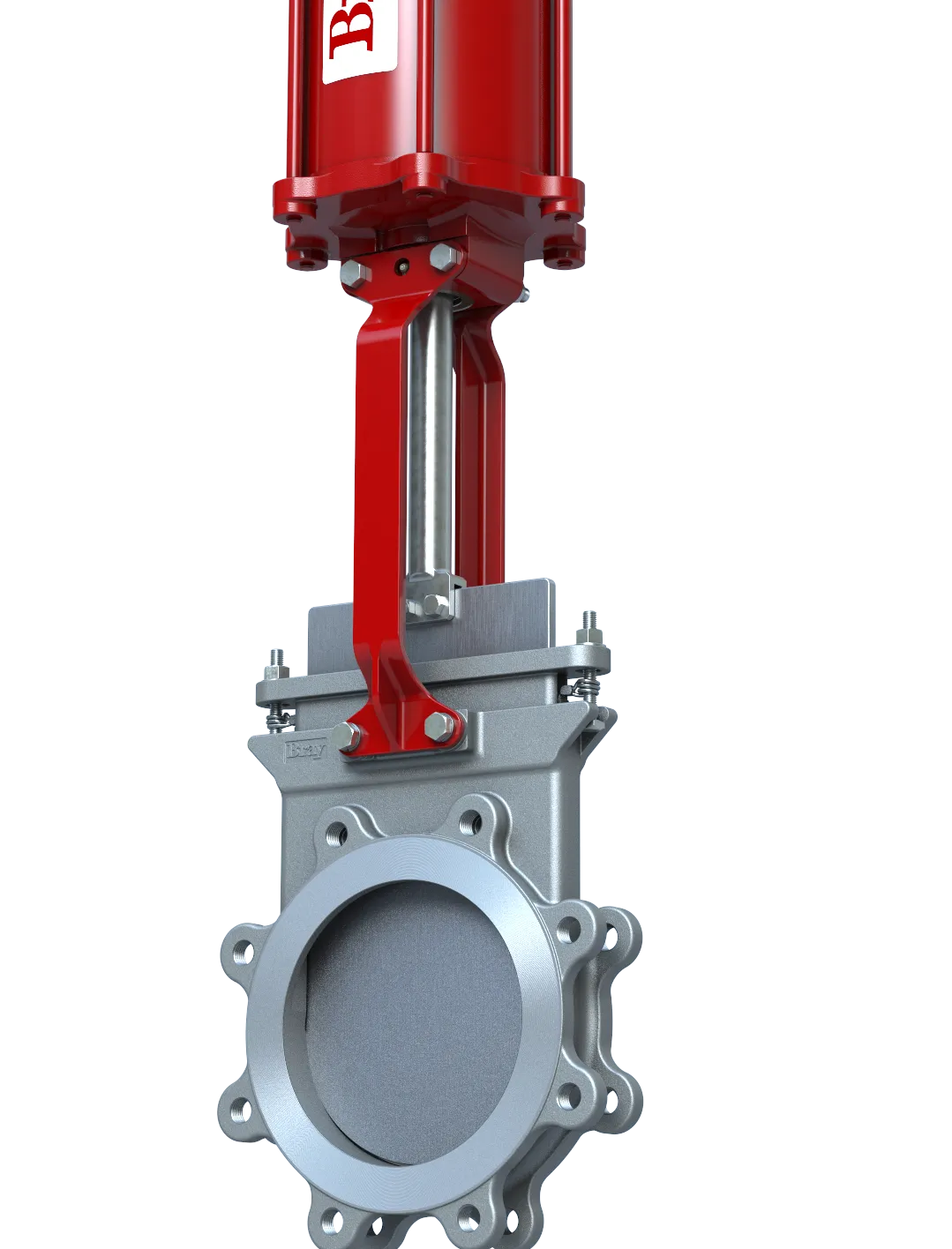

A. Topworks

Topworks designed for easy, quick conversion between manual and pneumatic actuation. Manual valves include a lubricant injection port for continuous, smooth operation with minimal maintenance.

-

B. Clevis

Clevis design and horizontal bolting stabilizes gate ensuring proper alignment.

-

C. Packing (standard)

Standard multi-layer square packing provides exceptional gland sealing.

-

D. Packing (optional)

Optional energized quad seal packing for enhanced gland sealing.

-

E. Chest Liner / Anti Extrusion Ring

Chest liner for sizes up to 12" and PTFE anti- extrusion ring for sizes 14" and up.

-

F. Port

Unrestricted flow path with minimal pressure drop achieved through full port valve design.

-

G. Gate

Gate design ensures consistent alignment throughout the length of the stroke.

-

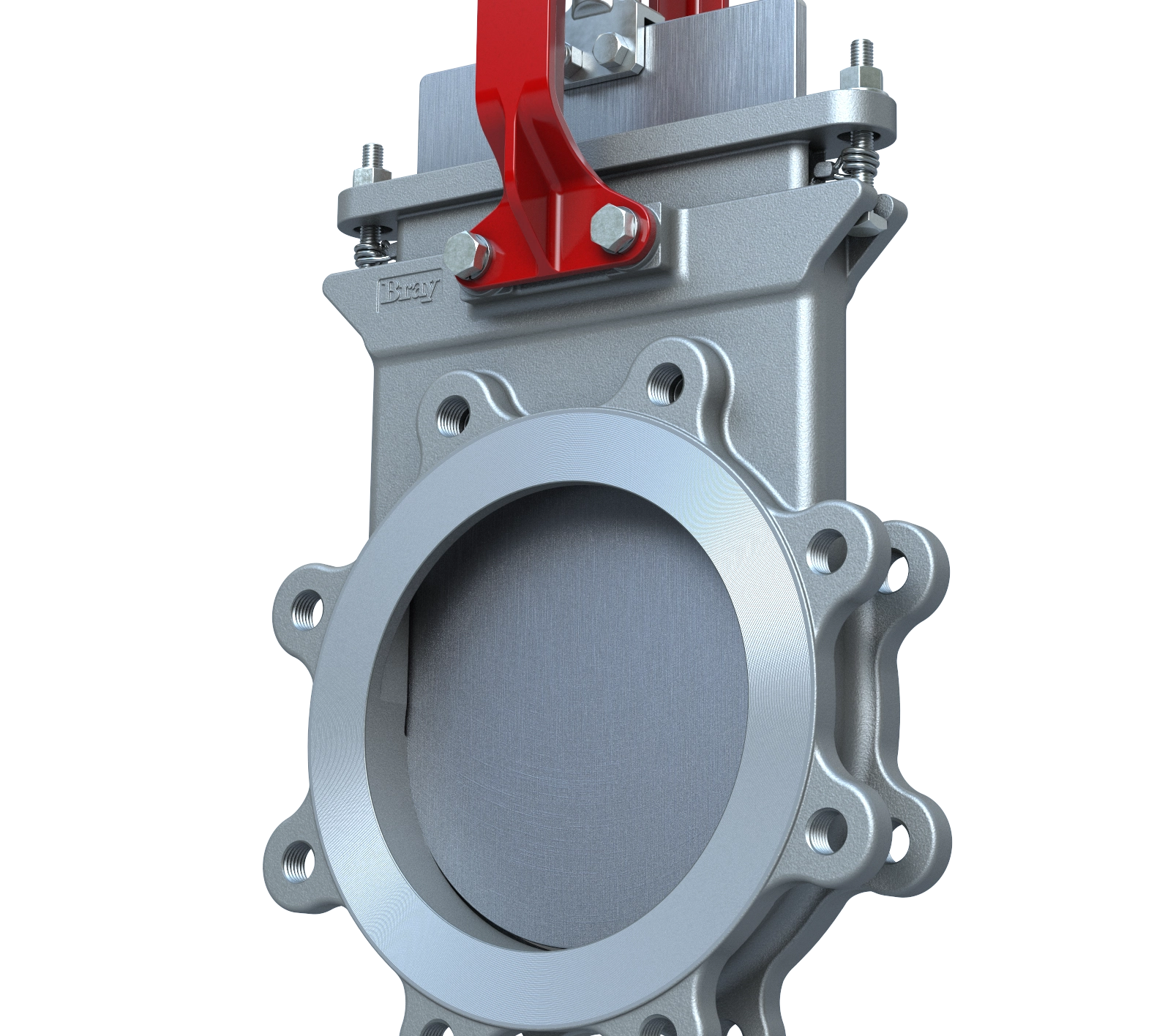

H. Seat

Mechanically retained steel reinforced elastomer seat ensures bidirectional zero leakage shutoff.

-

I. Yoke

Cast yoke superstructure ensures robustness in valve design for different operators/orientation.

Explore More Bray Insights

Learn Even More About How Bray’s Solutions Can Impact Your Business

.webp)

.webp)