More Details

Features & Benefits

- Pressure rating of 240psi (16bar), accommodating a wide spectrum of industrial applications.

- Compliant with ASME B16.5 CL150 drilling standards, ensuring seamless compatibility and integration within existing systems.

- Configured in a two-piece bolted wafer design, optimizing space utilization and offering installation flexibility.

- Packing Options: PTFE impregnated synthetic fiber, PTFE w/Buna-N Quad Seal, PTFE w/Viton® Quad Seal.

-

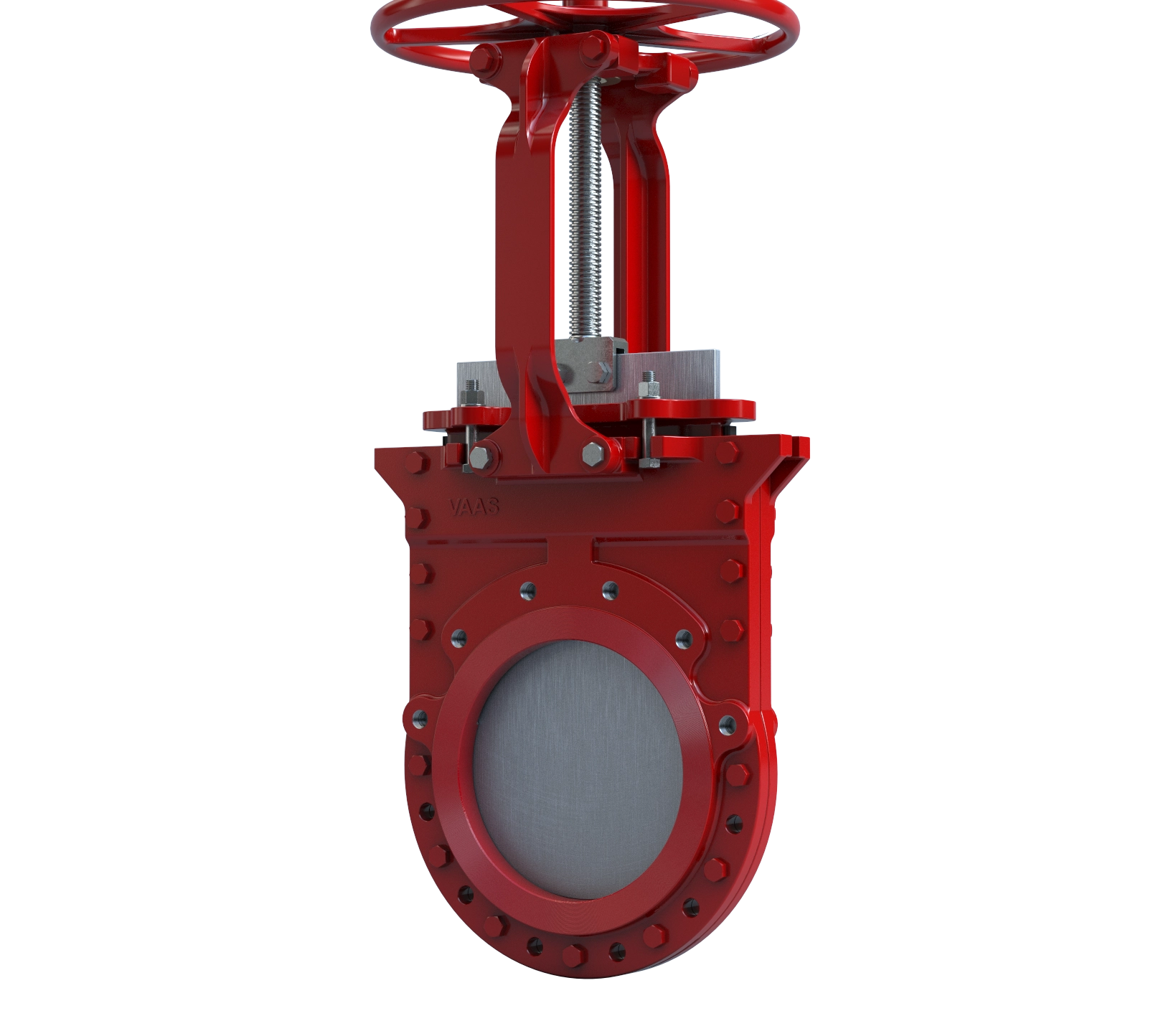

A. Topworks

Designed for easy, quick conversion between manual and pneumatic actuation. Featuring a lubricant injection port for continuous, smooth operation with minimal maintenance.*

-

B. Clevis

Clevis design and horizontal bolting stabilizes gate ensuring proper alignment.

-

C. Packing (standard)

Standard multi-layer square packing provides exceptional gland sealing.

-

D. Packing (optional)

Optional energized quad seal packing for enhanced gland sealing.

-

E. Unrestricted Flow Path

Unrestricted flow path with minimal pressure drop achieved through full port valve design.

-

F. Gate

Deflection resistant gate design ensures consistent alignment for industry leading durability.

-

G. Seat

Replaceable steel reinforced elastomer seat ensures bidirectional zero leakage shutoff.

-

H. Body

Two piece bolted body for easy maintenance and seat replacement.

Explore More Bray Insights

Learn Even More About How Bray’s Solutions Can Impact Your Business

.webp)

.webp)