More Details

Features & Benefits

- Designed for easy, quick conversion between manual and pneumatic actuation. Featuring a lubricant injection port for continuous, smooth operation with minimal maintenance

- Clevis design and horizontal bolting stabilizes gate ensuring proper alignment

- Standard multi-layer square packing provides exceptional gland sealing

- Optional energized quad seal packing for enhanced gland sealing

- Standard integral metal seat with optional replaceable zero leakage resilient seats

- Deflection resistant gate design ensures consistent alignment for industry leading durability

- Unique body design with no dead pockets enables self-draining of valve

- Lugged body suitable for all mounting orientations including dead-end service

-

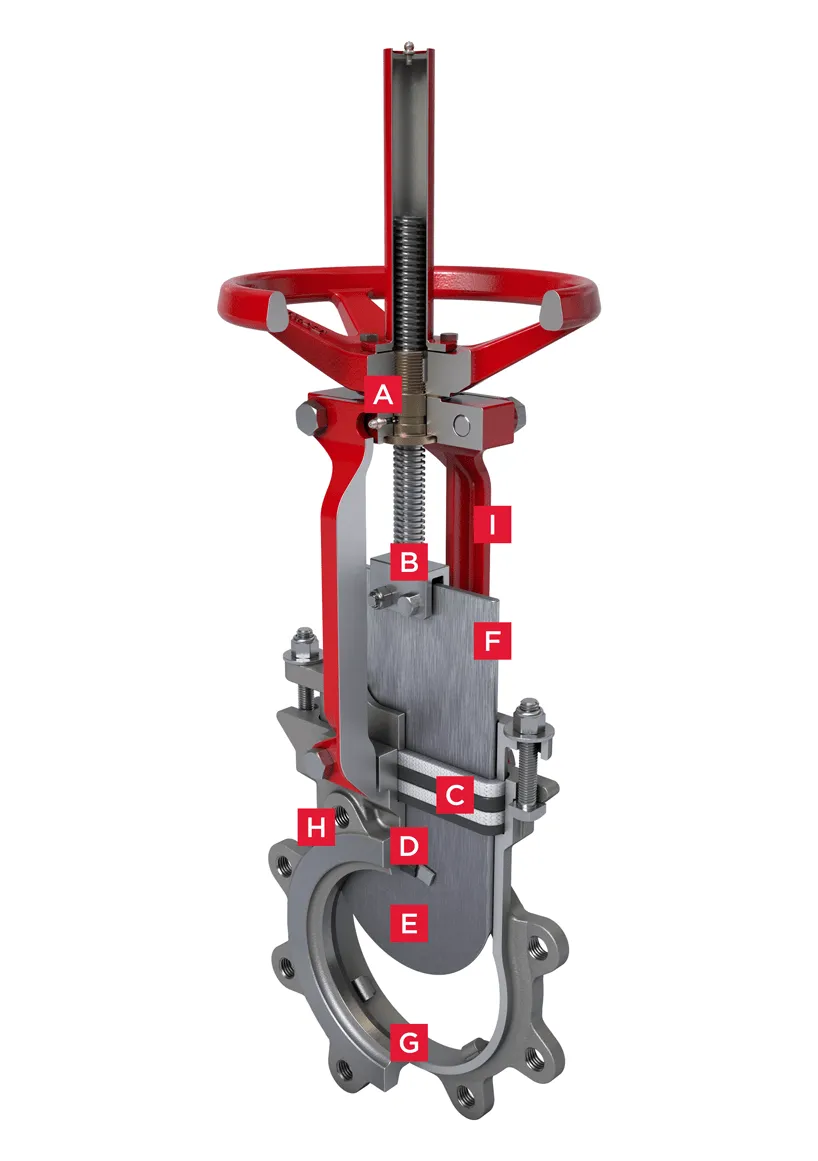

A - Topworks

Topworks designed for easy, quick conversion between manual and pneumatic actuation. Manual valves include a lubricant injection port for continuous, smooth operation with minimal maintenance.

-

B - Clevis

Clevis design and horizontal bolting stabilizes gate ensuring proper alignment.

-

C - Packing

Standard multi-layer square packing provides exceptional gland sealing.

-

D - Energized Quad Seal Packing (Optional)

Optional energized quad seal packing for additional leak prevention.

-

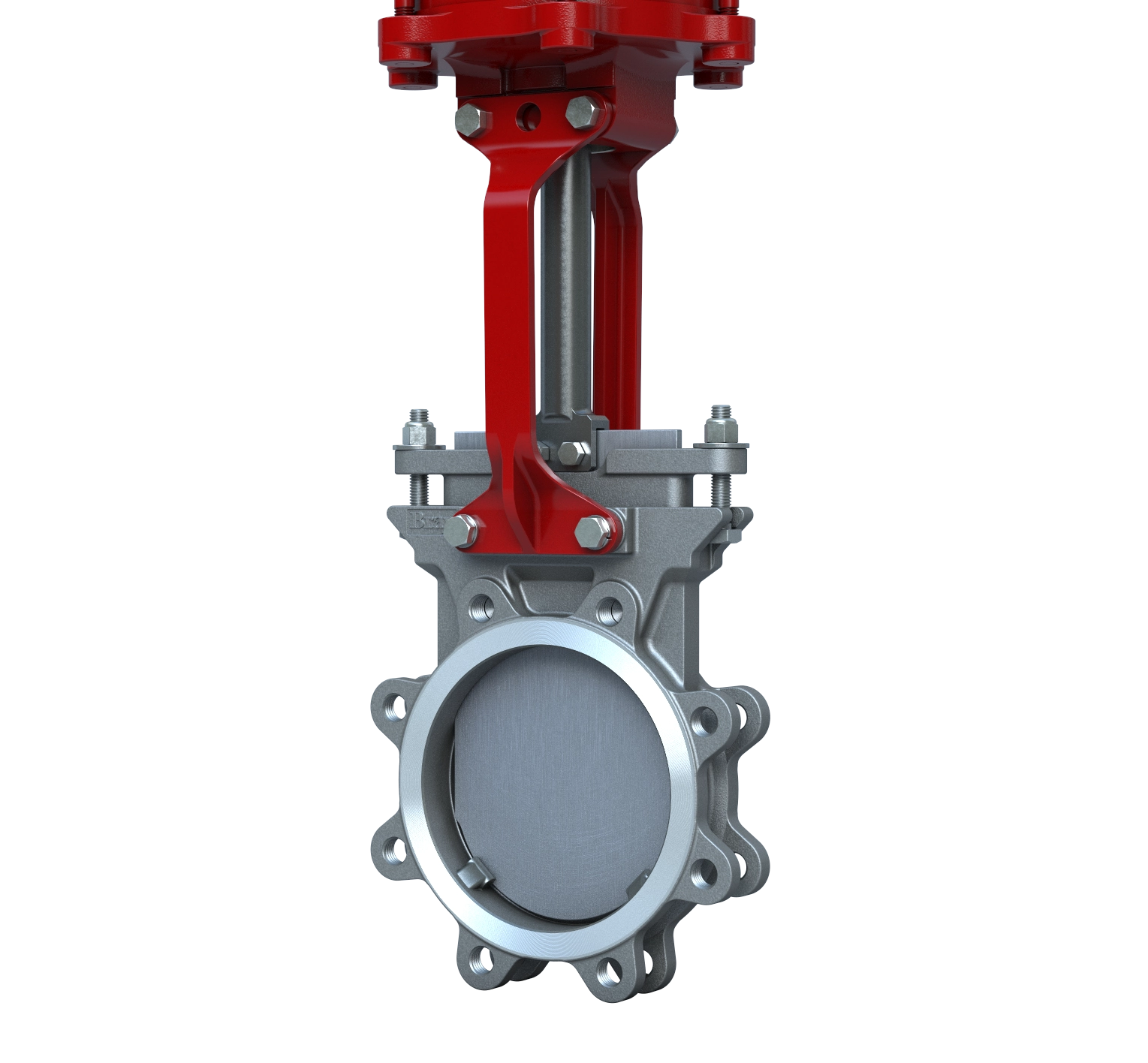

E - Integral Metal Seat

Standard integral metal seat and optional replaceable zero leakage resilient seats.

-

F - Gate

Gate design ensures consistent alignment throughout the length of the stroke.

-

G - Body

Unique body design with no dead pockets enables self-draining of valve.

-

H - Lugged Body

Lugged body suitable for all mounting orientations including dead-end service.

-

I - Cast Yoke Superstructure

Cast yoke superstructure ensures robustness in valve design for different operators/orientation.

Explore More Bray Insights

Learn Even More About How Bray’s Solutions Can Impact Your Business

-copy.webp)