More Details

Features & Benefits

-

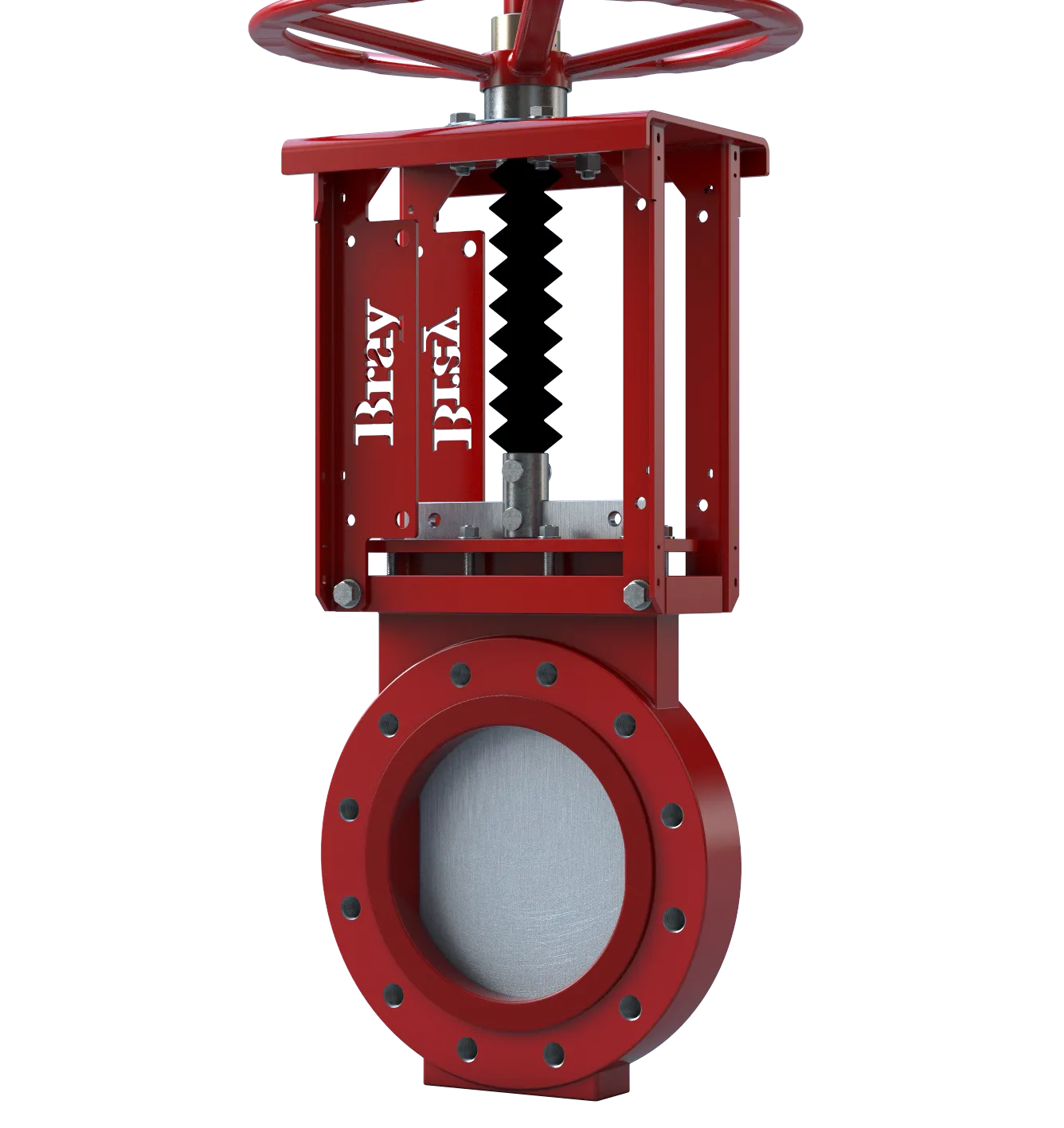

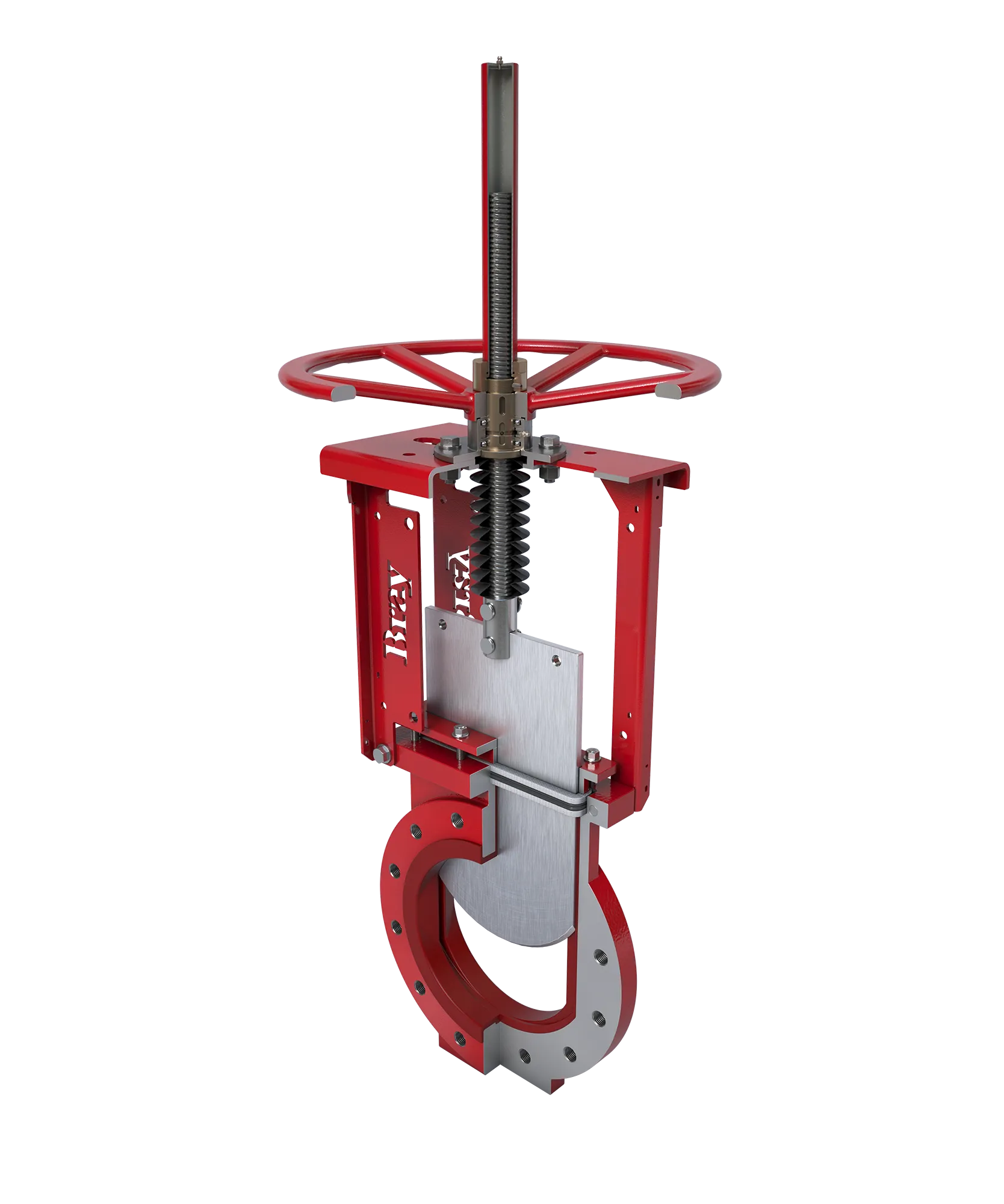

A. Stem Cover

Protective stem cover is standard increasing cycle life in hazardous environments.

-

B. Packing Gland

Live-loaded packing gland extends gate life preventing leakage and discharge from top of valve.

-

C. Body

Standard one piece ductile iron body with molded urethane liner throughout.

-

D. Liner

Urethane body liner is rated up to 80°C/176°F and completely protects valve body from abrasive line media. (UMP 241 90 Shore, PTMEG-TDI)

-

E. Unrestricted Flow Path

Unrestricted flow path with minimal pressure drop achieved through full port valve design for extended valve life.

-

F. Gate

Robust gate available in a wide range of corrosion resistant alloys to suit the application.

-

G. Seat

Seat and port designed to be flush eliminating cavities where media can collect and prevent full gate closure.

Explore More Bray Insights

Learn Even More About How Bray’s Solutions Can Impact Your Business

.webp)

.webp)