More Details

Features & Benefits

-

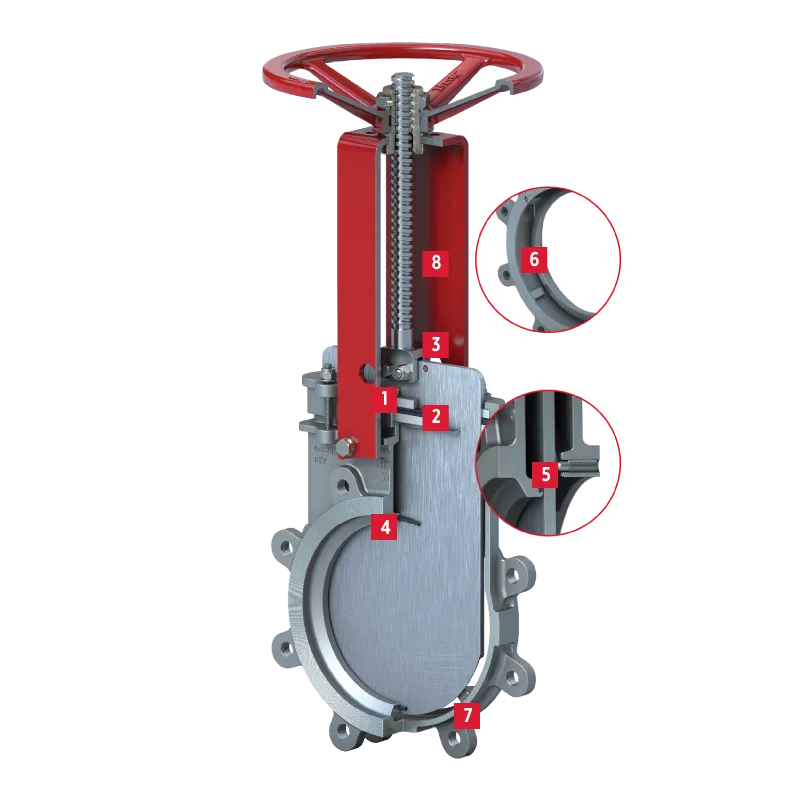

1. Extended Life: Inverted Packing Gland

Inverted packing gland extends packing life and simplifies replacement.

-

2. Exceptional Sealing: Standard Quad Seal Packing

Standard energized quad seal packing provides exceptional gland sealing.

-

3. Stabilized Alignment: Clevis Gate Design

Clevis design and horizontal bolting stabilizes gate ensuring proper alignment.

-

4. Versatile Seating Options: Metal, RPTFE, O-Ring

Standard metal seated, also available with optional unique self-locking RPTFE seat or replaceable O-Ring soft seat for high performance unidirectional sealing.

-

5. Fine-Tuned Contact: Adjustable Gate Guides

Adjustable gate guides provided to fine tune the gate-to-seat contact and assist with back pressure.

-

6. Precision Sealing: Cast-In Gate Guides

Cast in gate guides eliminating welding in the body and precision machined wedging for ultimate sealing.

-

7. Maximized Performance: Optimized Body Design

Optimized body design is offered in both lugged (Series 943) and semi lugged (Series 953) design to maximize performance without unnecessary weight. Series 943 Lugged body suitable for all mounting orientations including dead-end service.

-

8. Robust Options: Carbon, Stainless, Alloy

Carbon steel, stainless steel, or alloy superstructure ensures robustness in valve design for different operators/orientation.

-

9. Protective Add-On: Replaceable Deflection Cone

Optional replaceable deflection cone, available in Chrome Iron and Polyurethane, can be provided to protect the seat from abrasive media.

Bray's Series 943 Knife Gate Valve

Optional deflection cone is shown.

Lug Body

2-24 150 psi | 50-600mm 10 bar

Bray's Series 953 Knife Gate Valve

Semi Lug Body

2-10 150 psi | 20-250 mm 10 bar

12-16 90 psi | 300-400 mm 6 bar

18 75 psi | 450 mm 5 bar

20-24 60 psi | |500-600 mm 4 bar

Explore More Bray Insights

Learn Even More About How Bray’s Solutions Can Impact Your Business