Sugar Cane Process Solutions

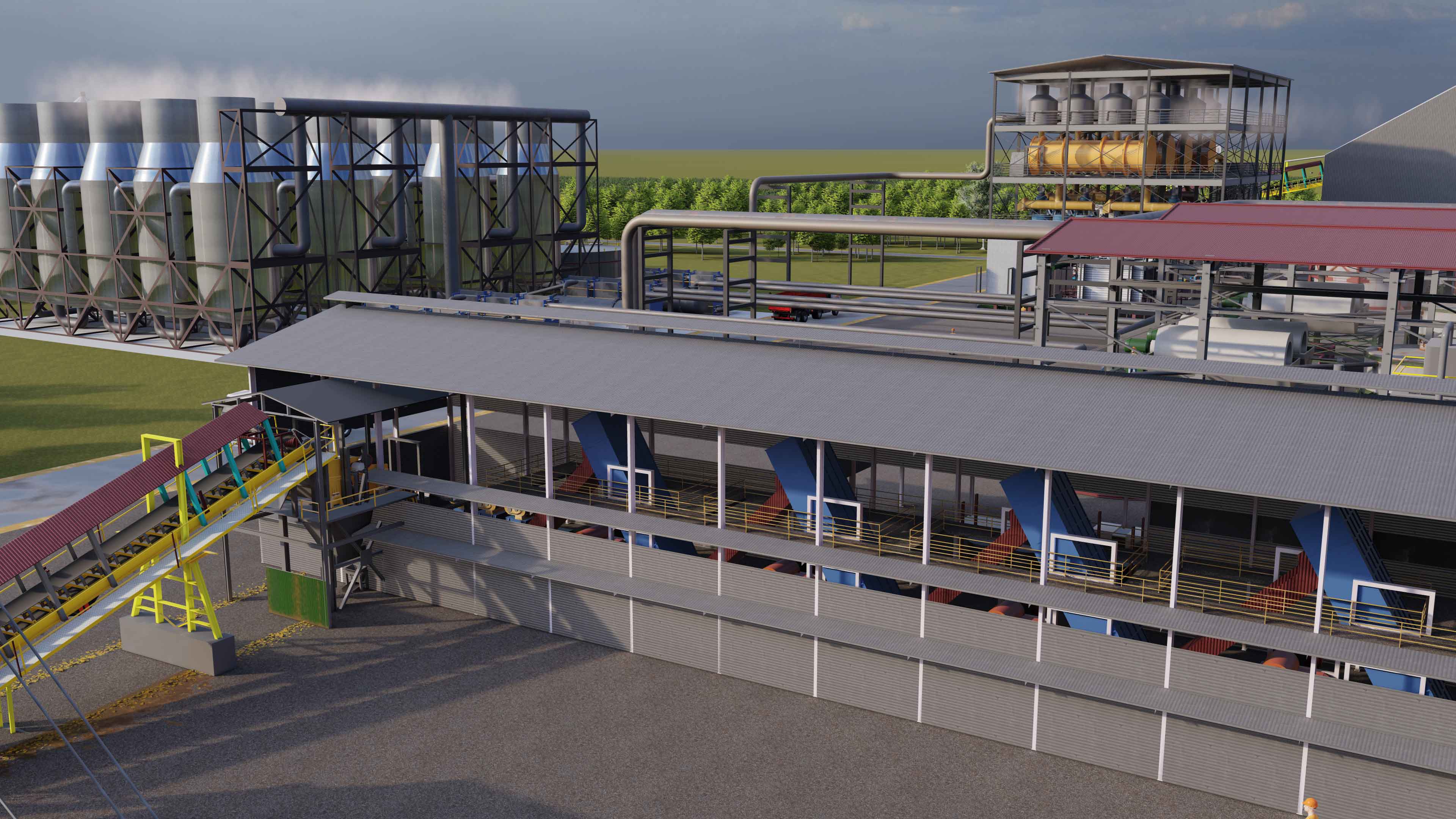

Crushing/Milling

Clarification

Evaporators

Vacuum Pans / Crystallization / Centrifuge

Molasses

Power Plant

Drying / Storage

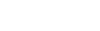

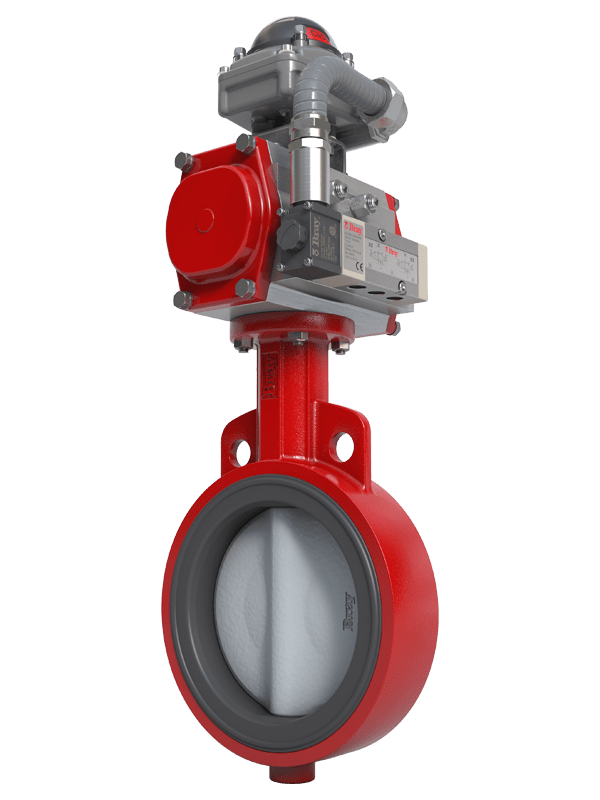

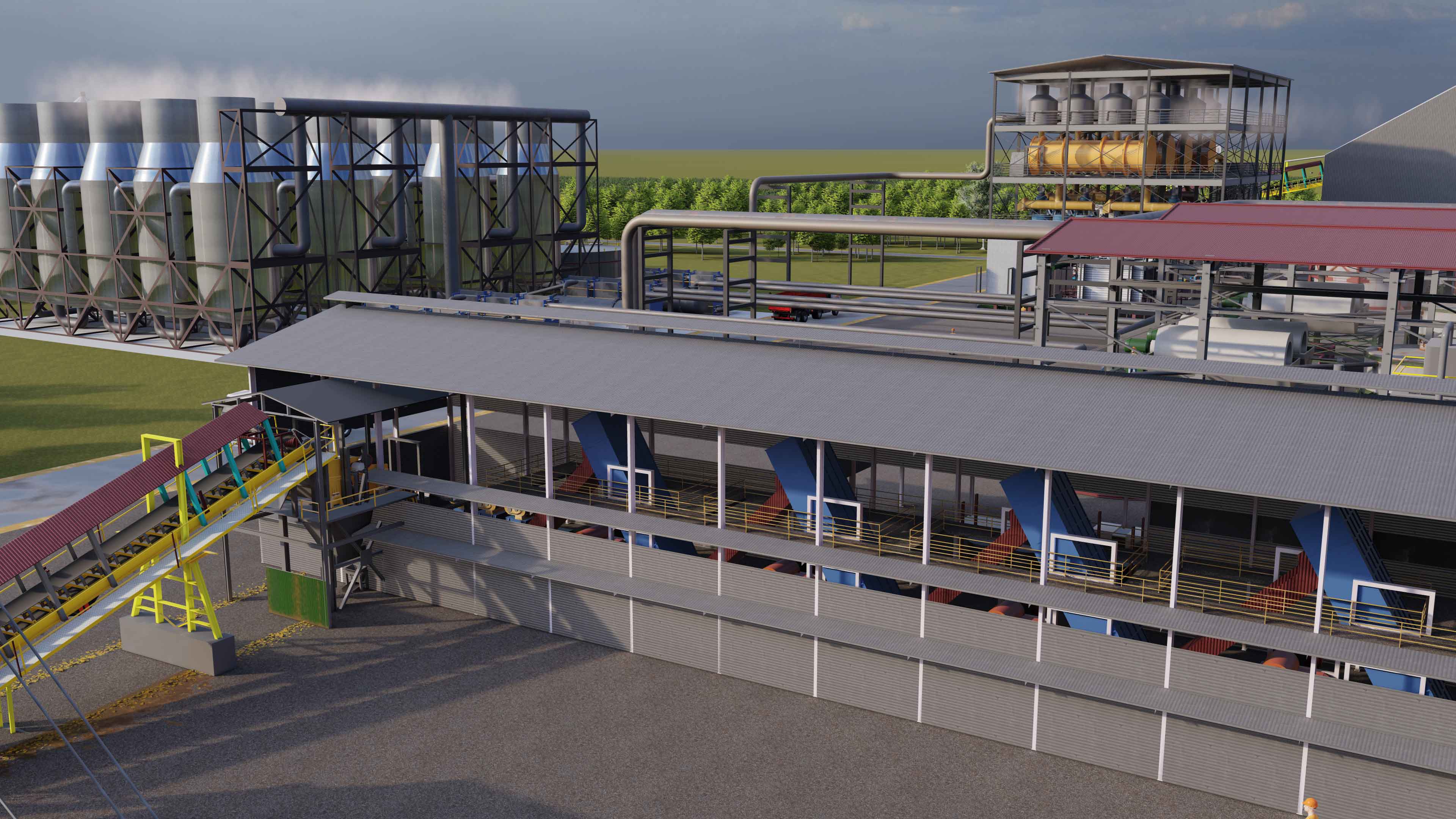

Crushing/Milling

This process breaks the sugar cane apart releasing the raw juice from the fibers.

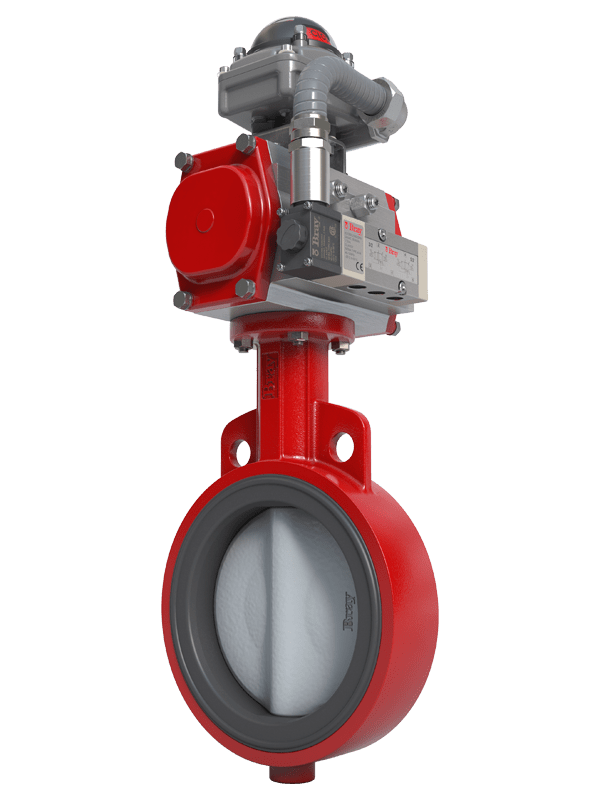

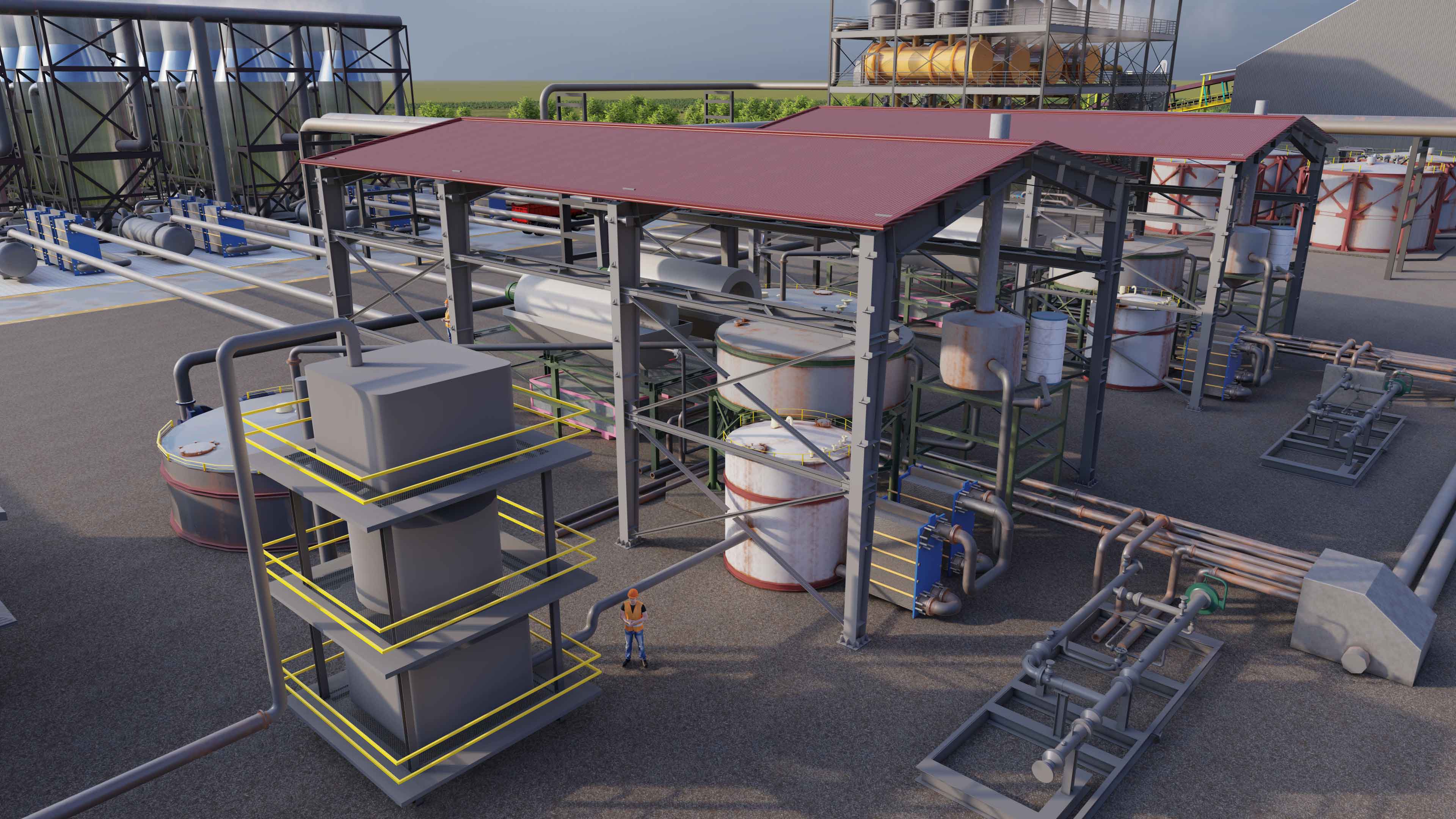

Clarification

Having extracted the raw juice, impurities like fibers, mud, rocks, sand and minerals need to be removed from the juice.

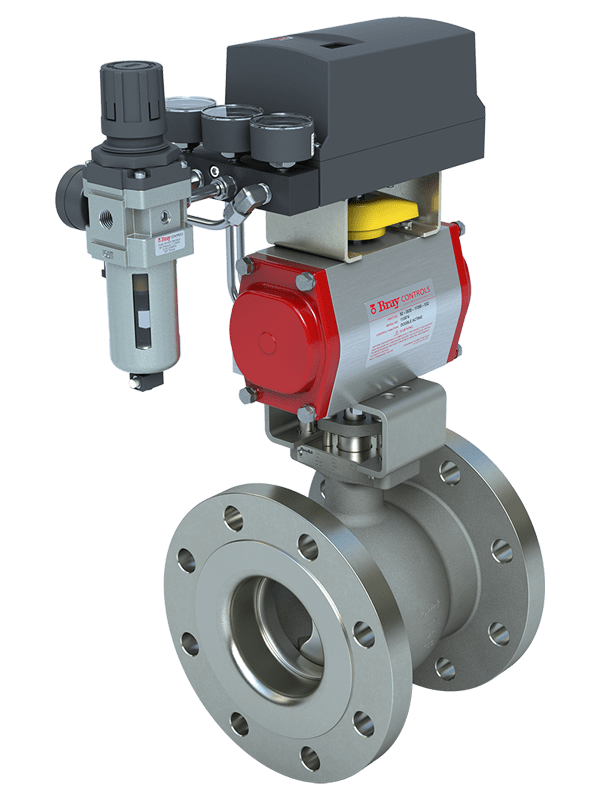

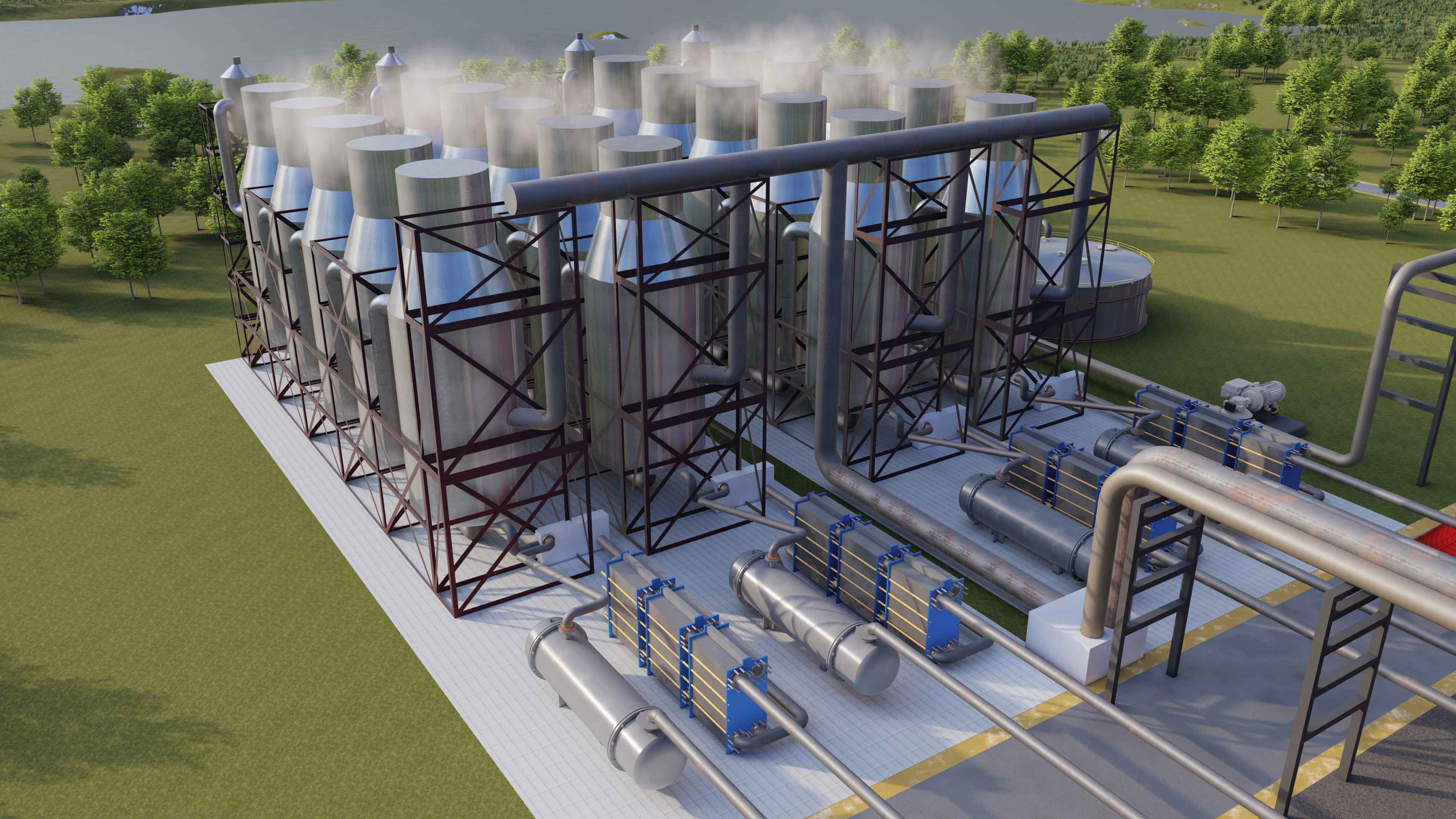

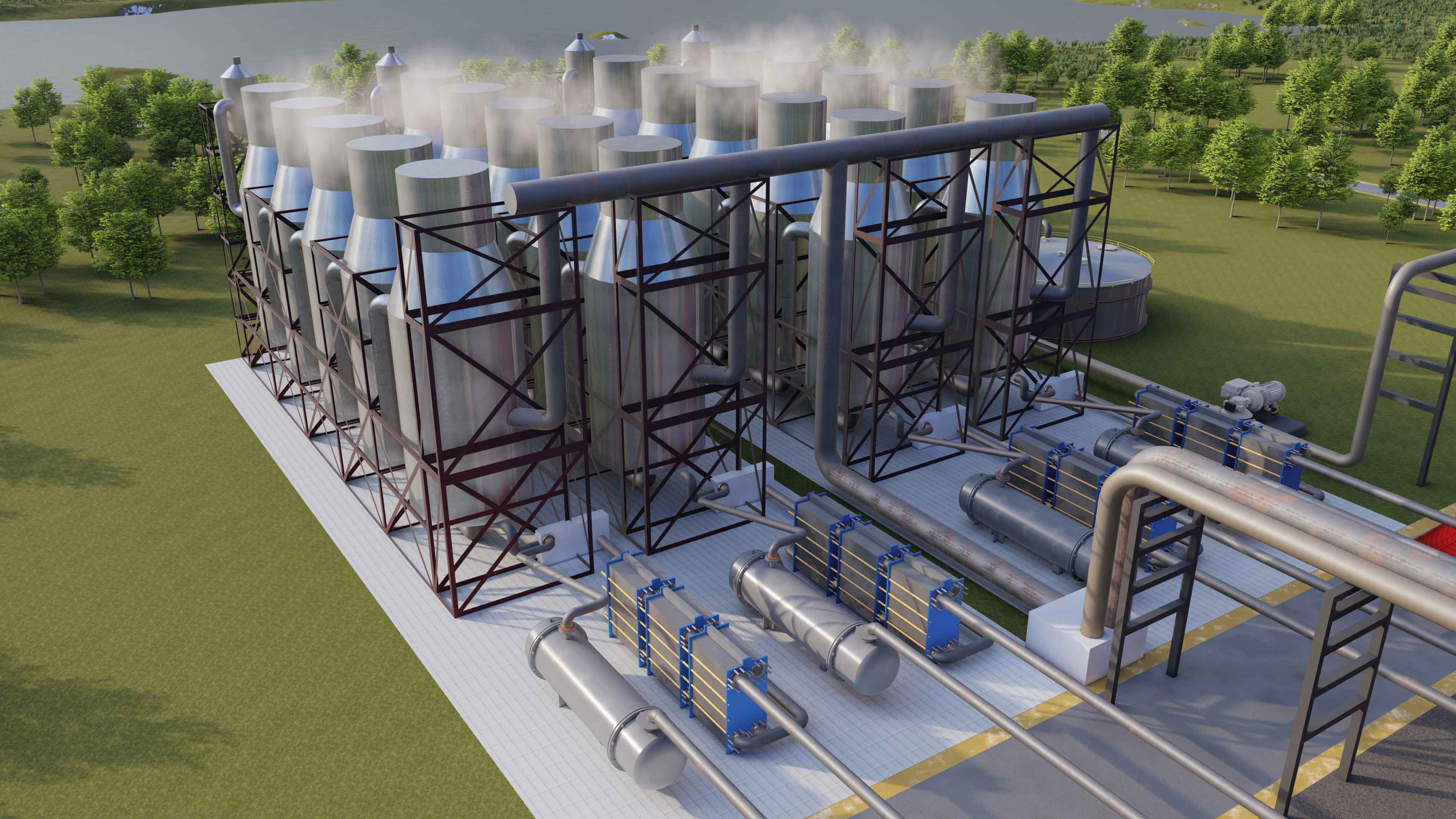

Evaporators

Clean juice moves through multiple evaporators heated by exhaust steam until it becomes syrup at 65%-70% solid content.

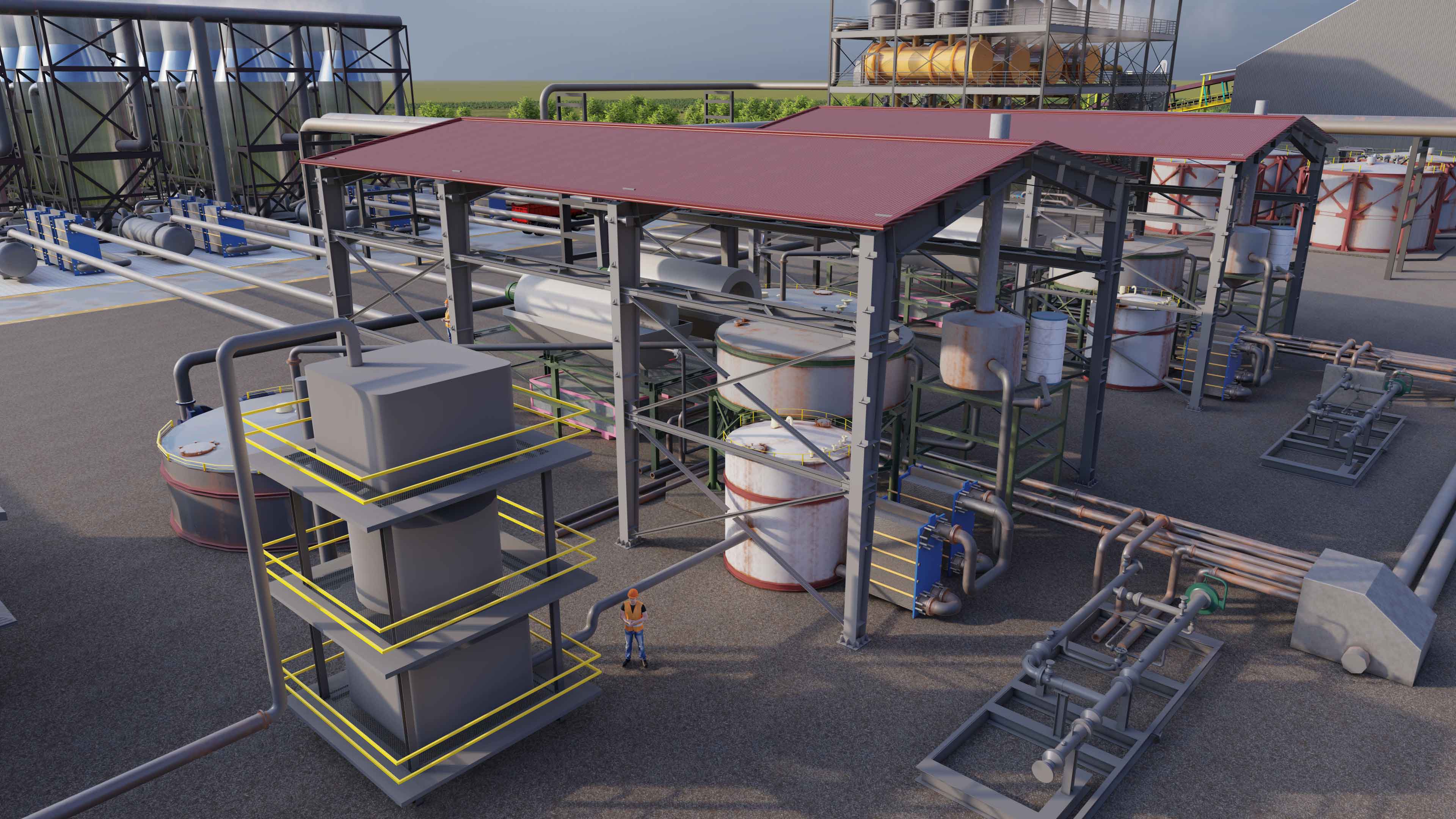

Vacuum Pans / Crystallization / Centrifuge

Sugar syrup is crystallized by further boiling and seeding till specified crystal size is reached.

Molasses

Syrup/Massecuitte is separated into wet sugar crystals and molasses by spinning them in a centrifuge.

Power Plant

Bagasse, coal and gas is used to make steam and electricity for the sugar factory.

Drying / Storage

The wet sugar crystals are dried in hot air dryers to prepare them for storage and bagging

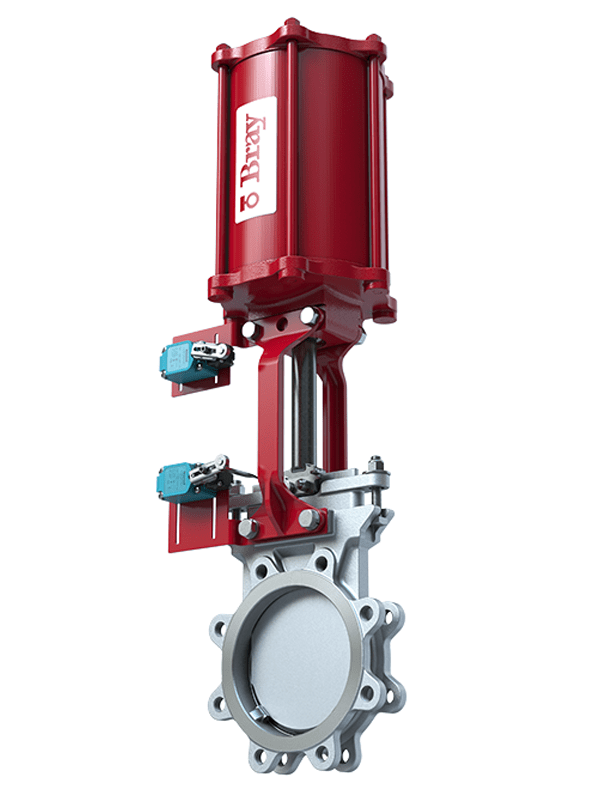

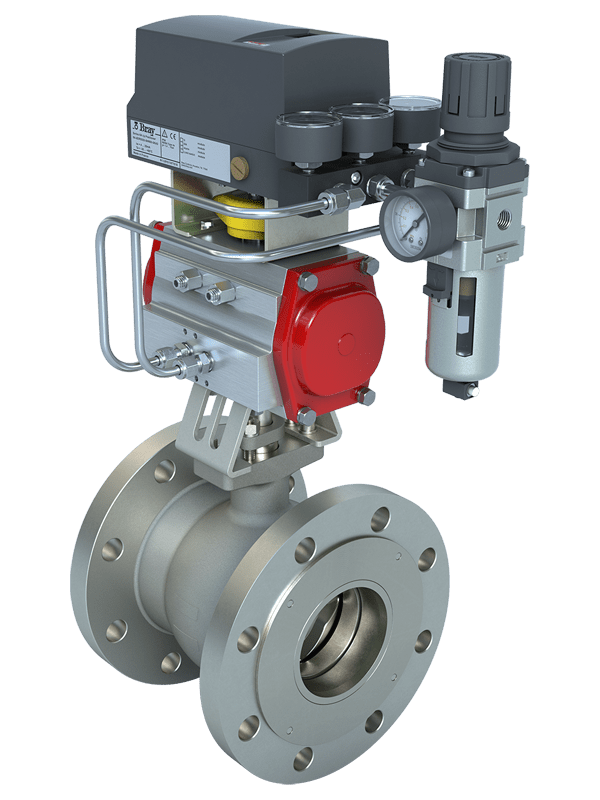

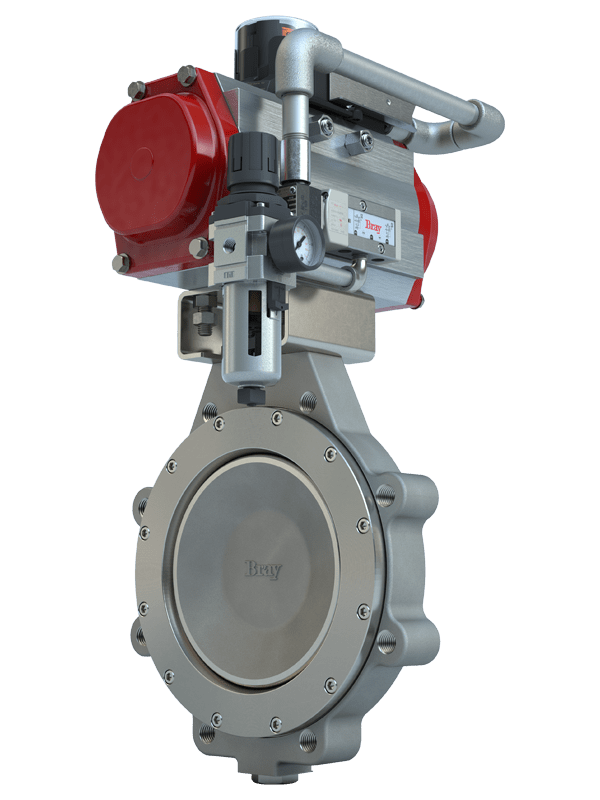

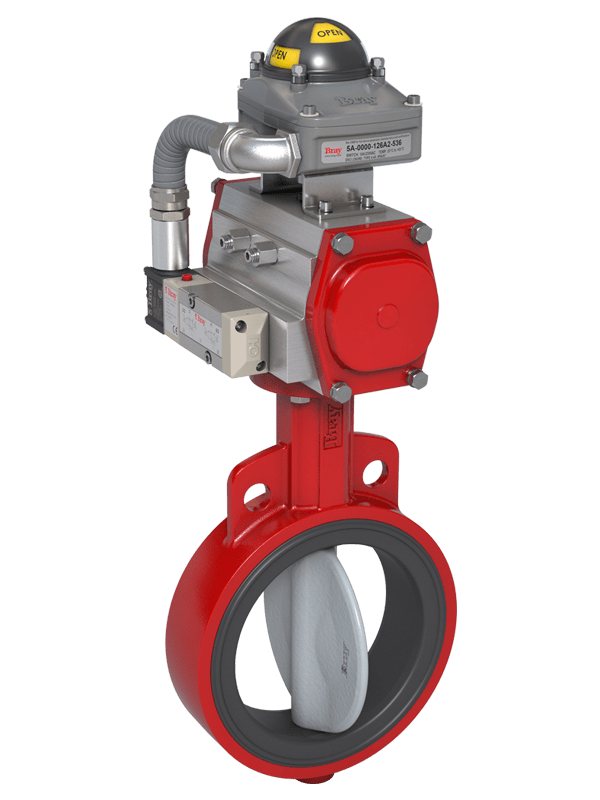

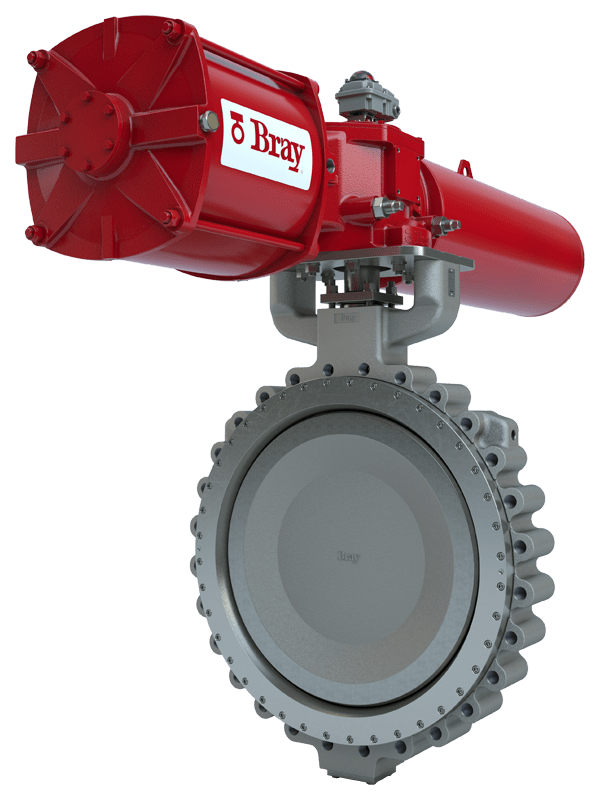

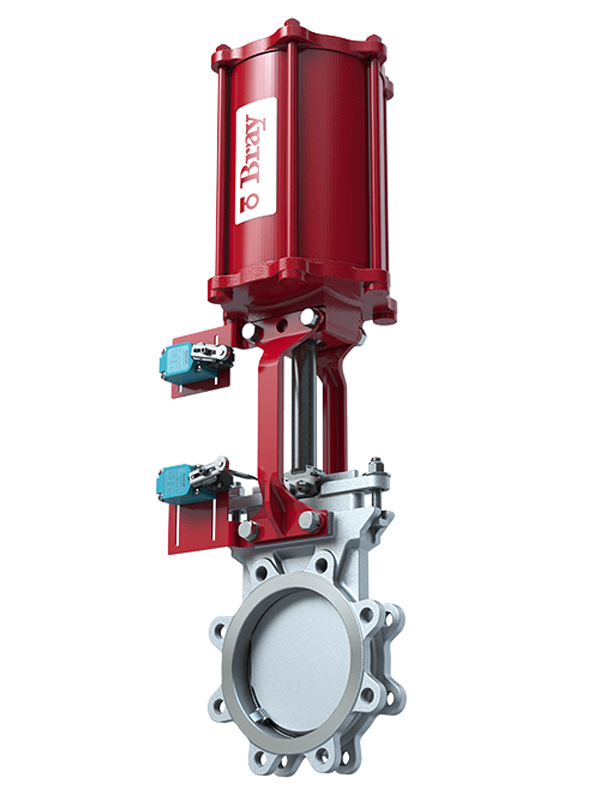

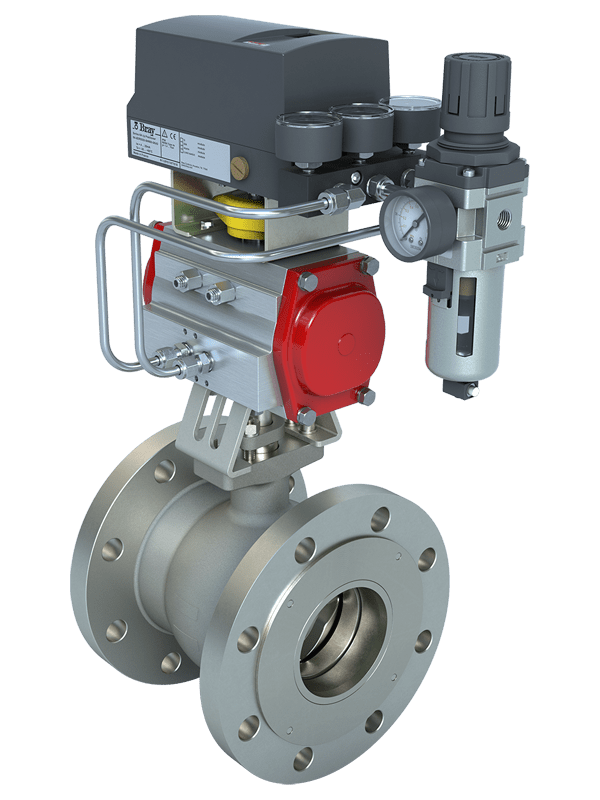

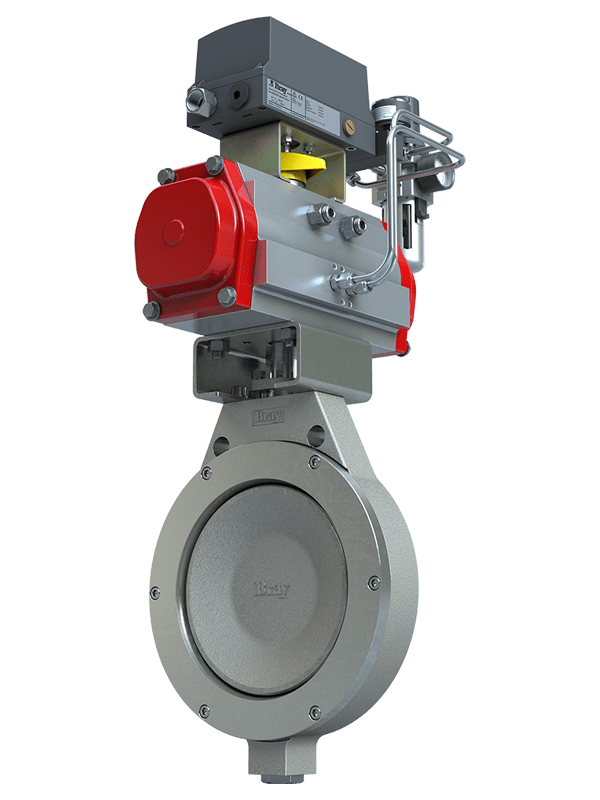

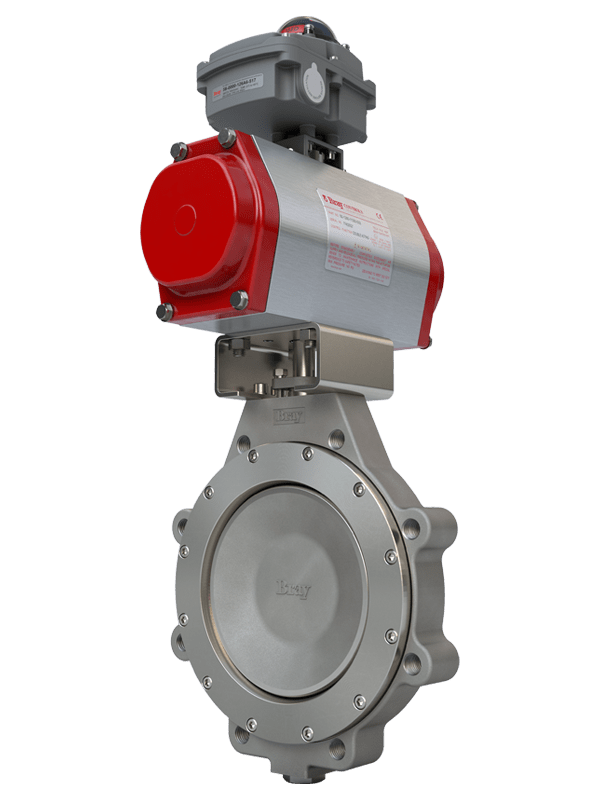

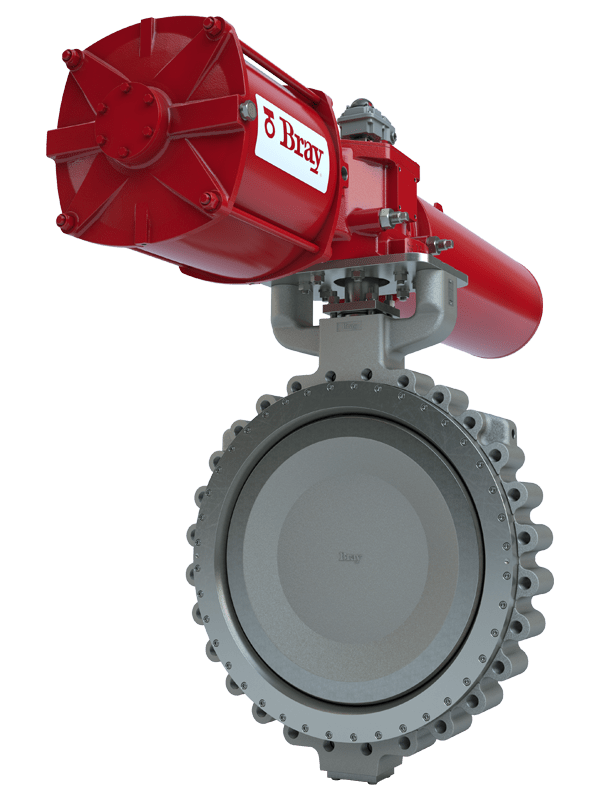

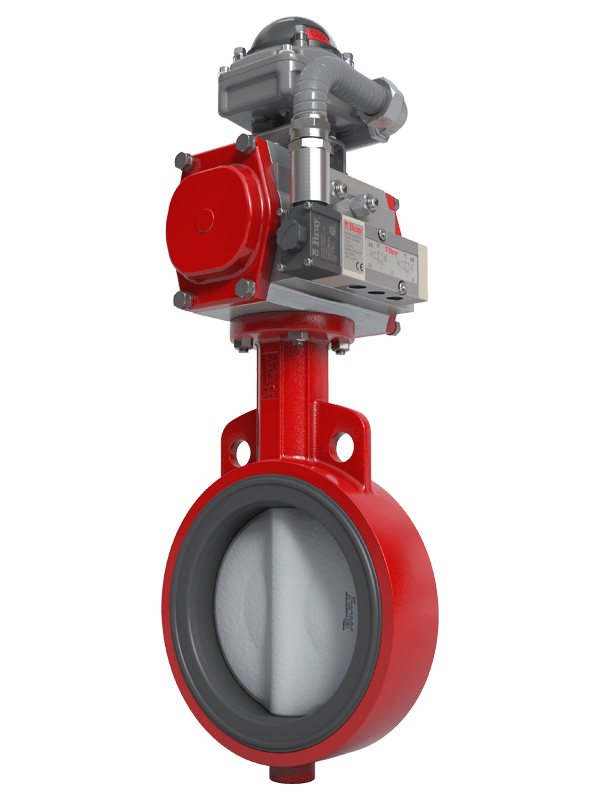

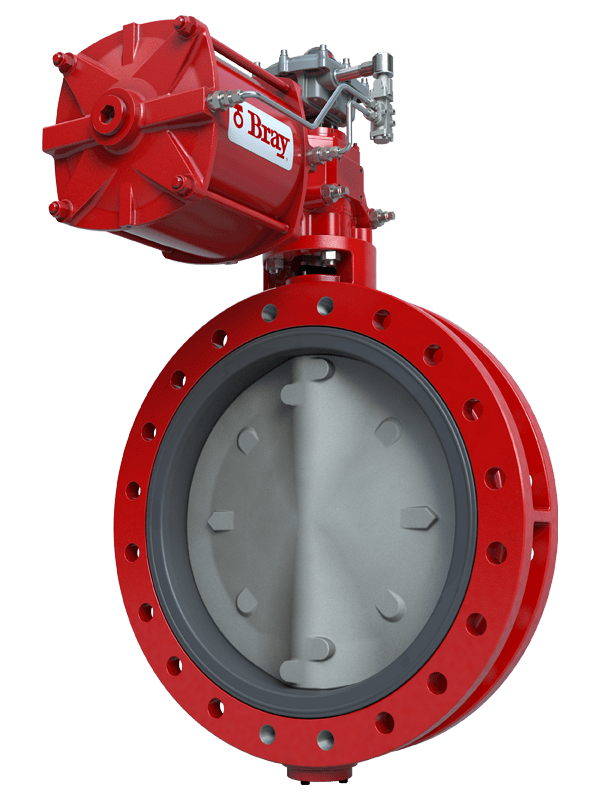

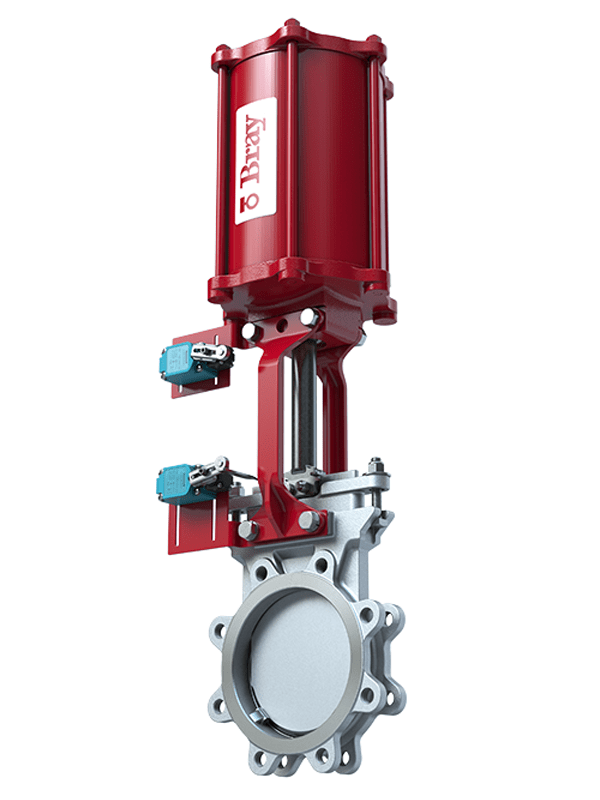

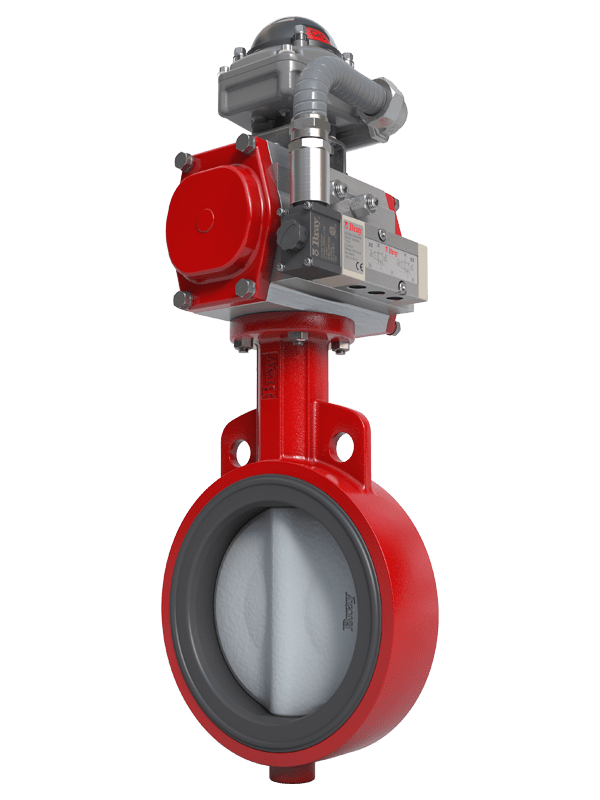

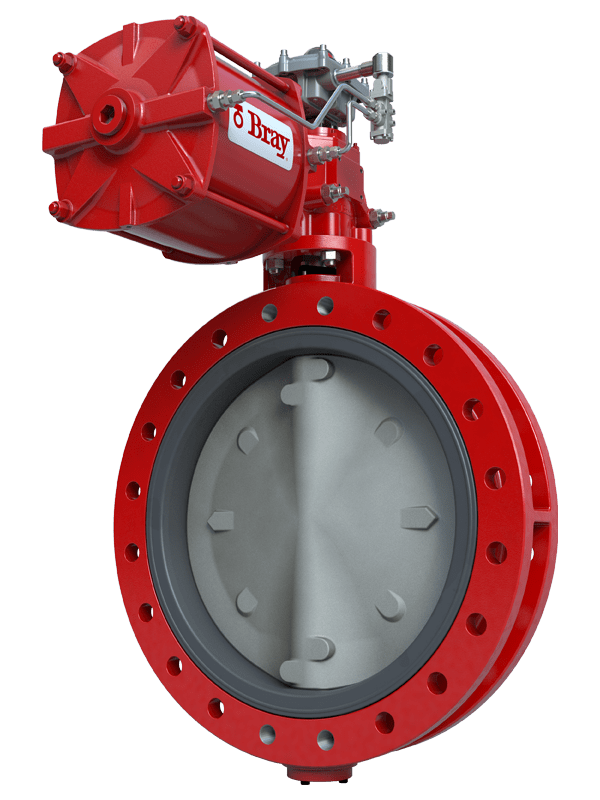

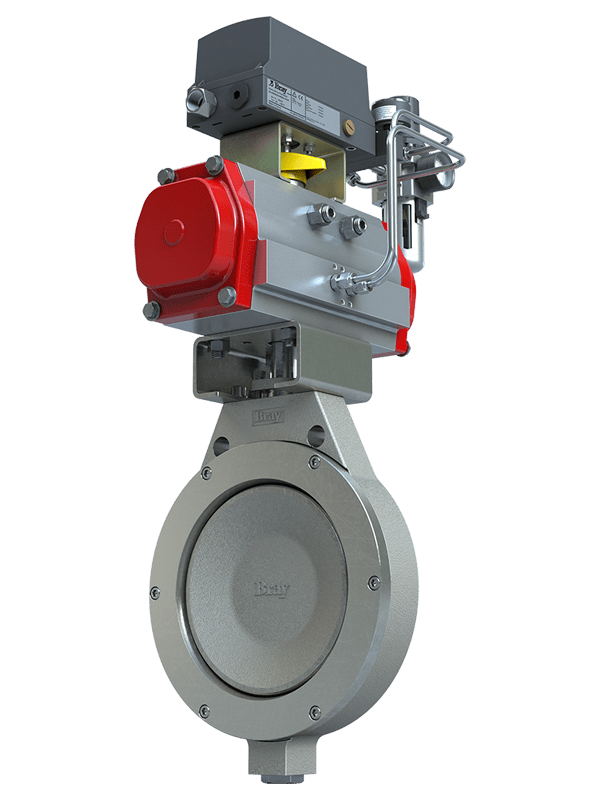

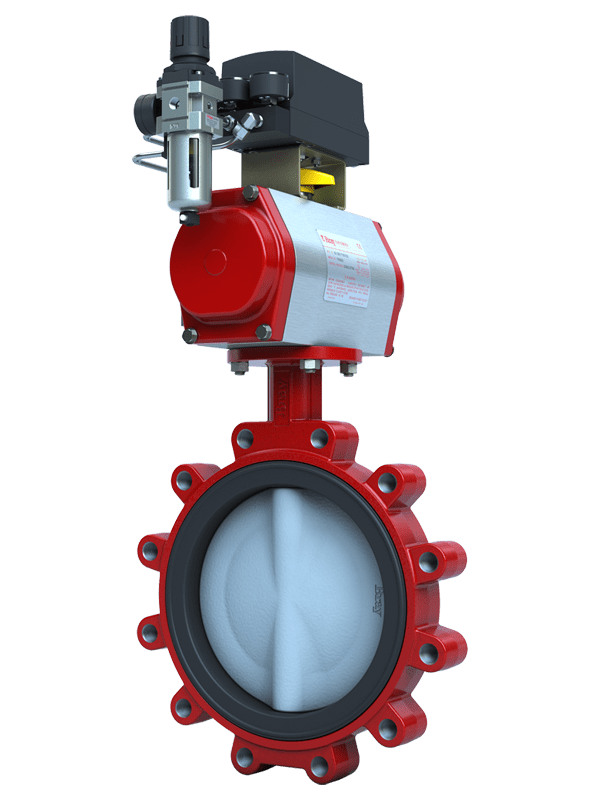

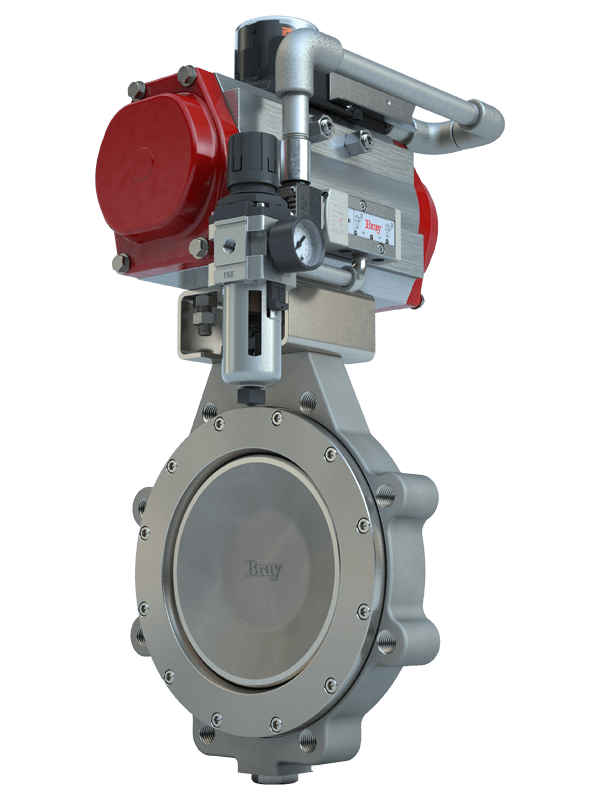

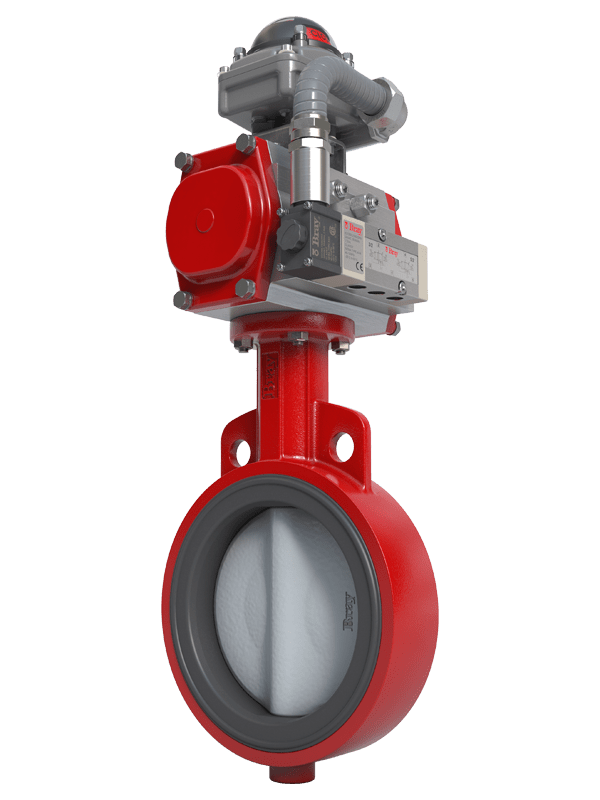

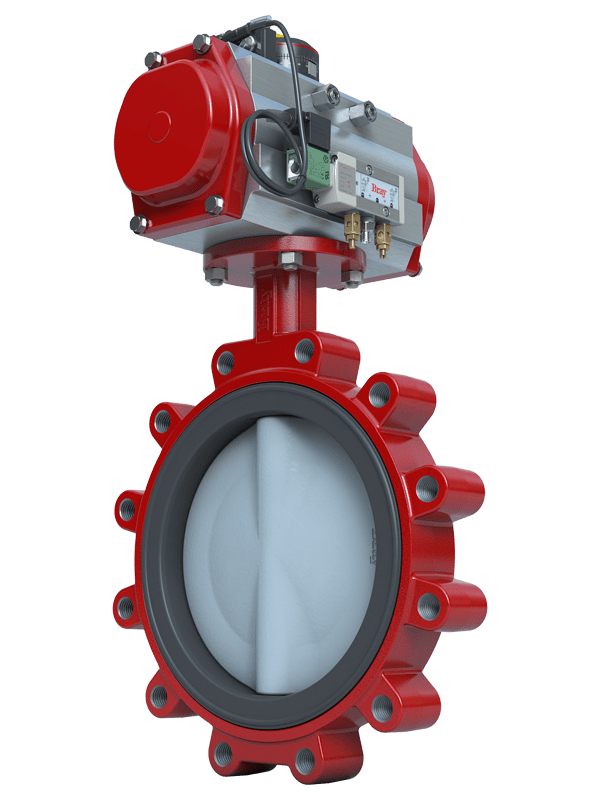

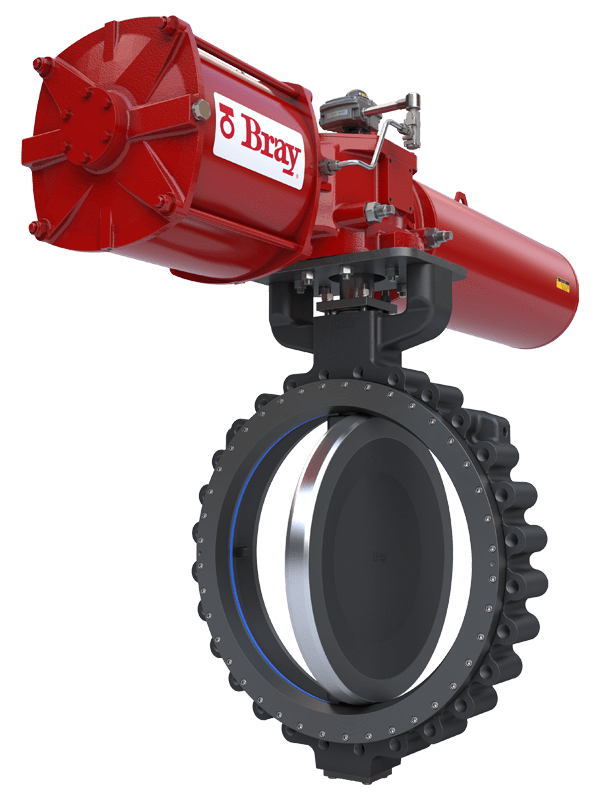

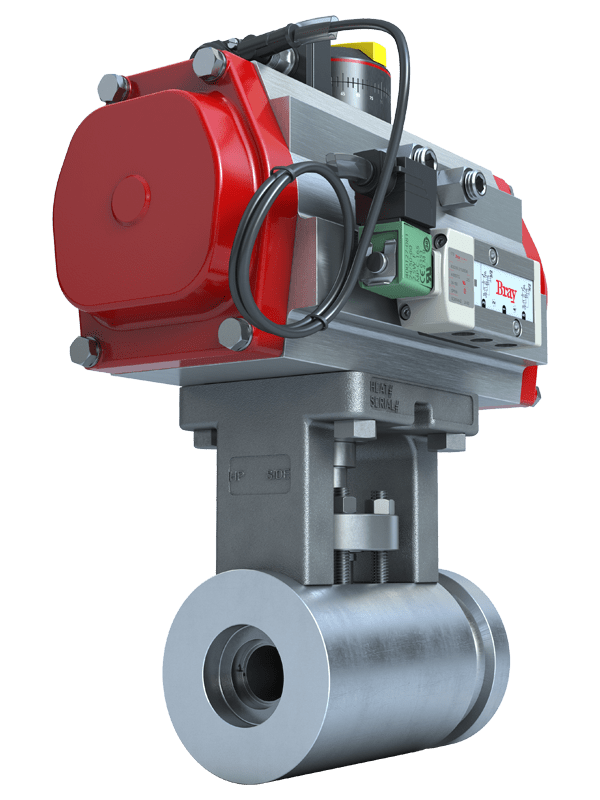

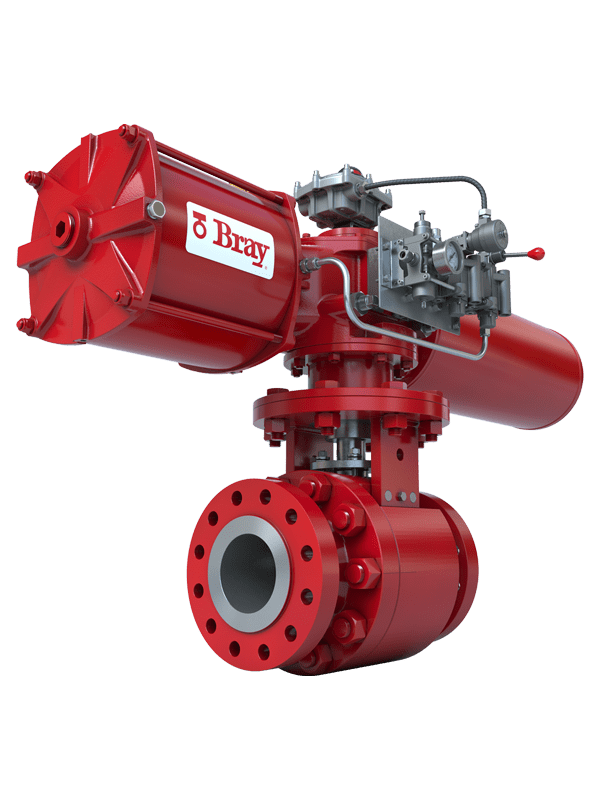

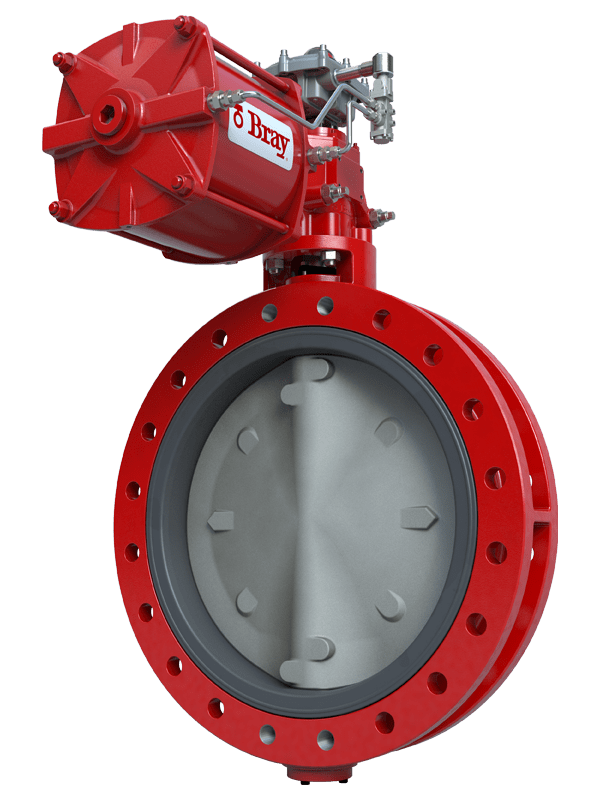

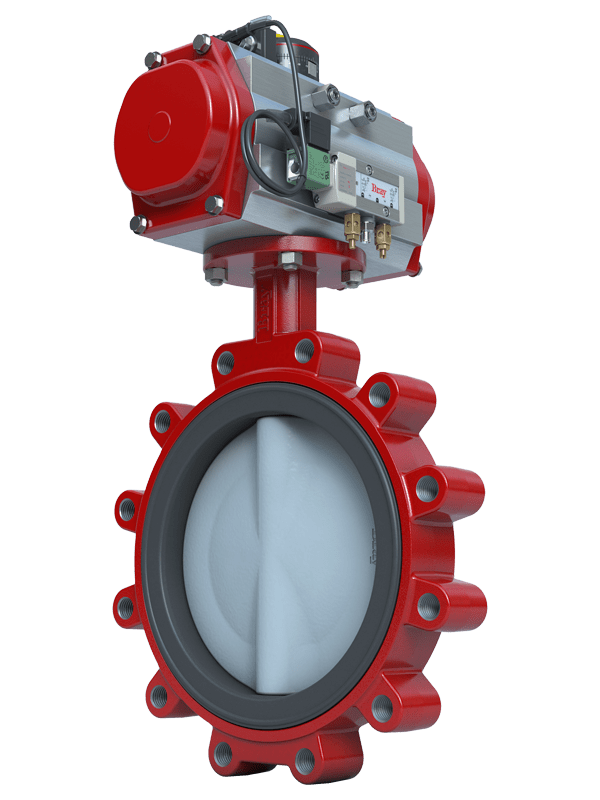

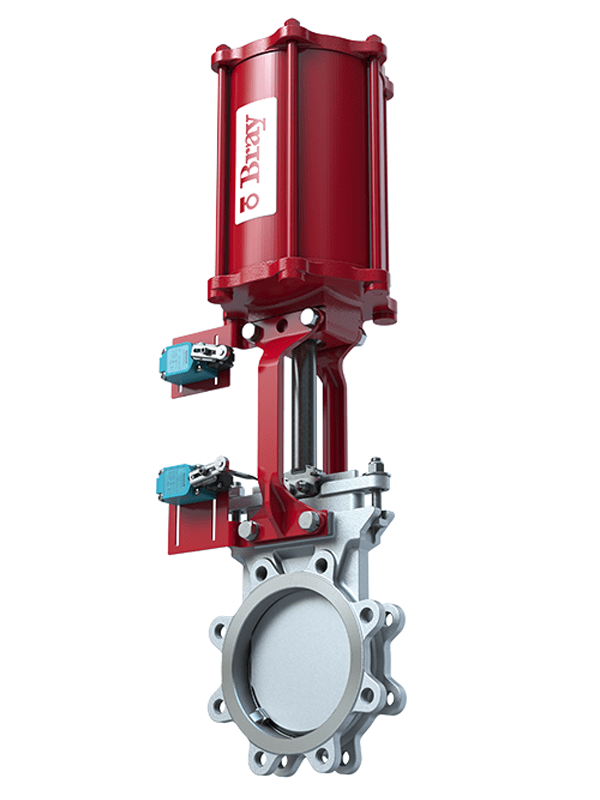

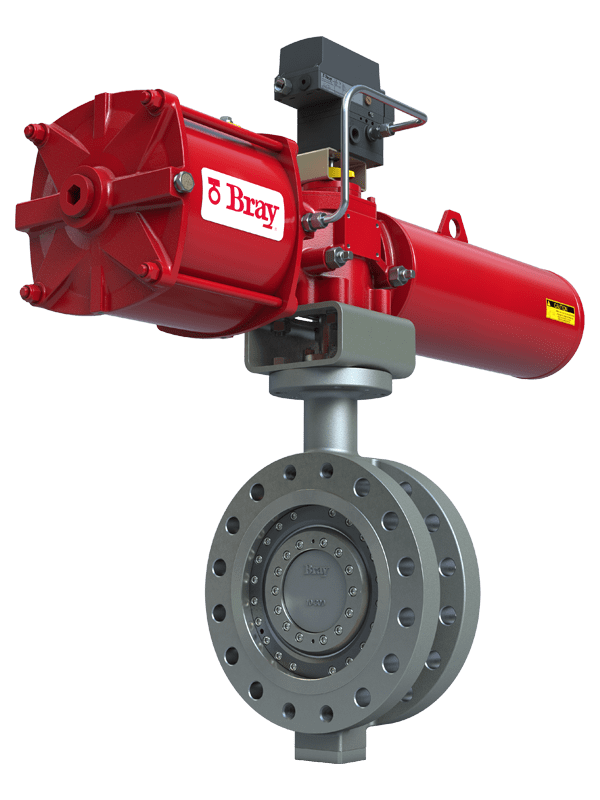

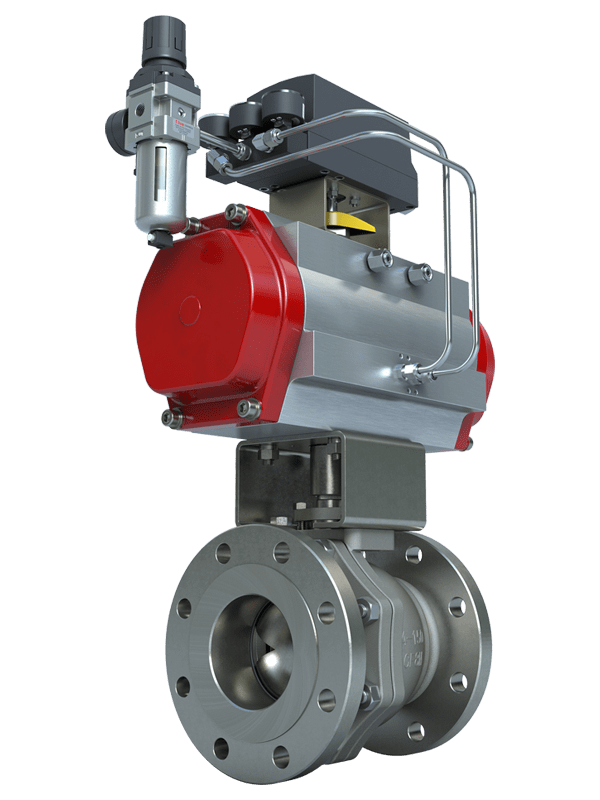

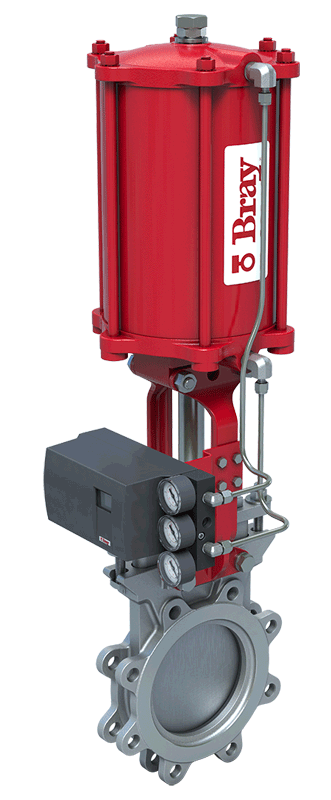

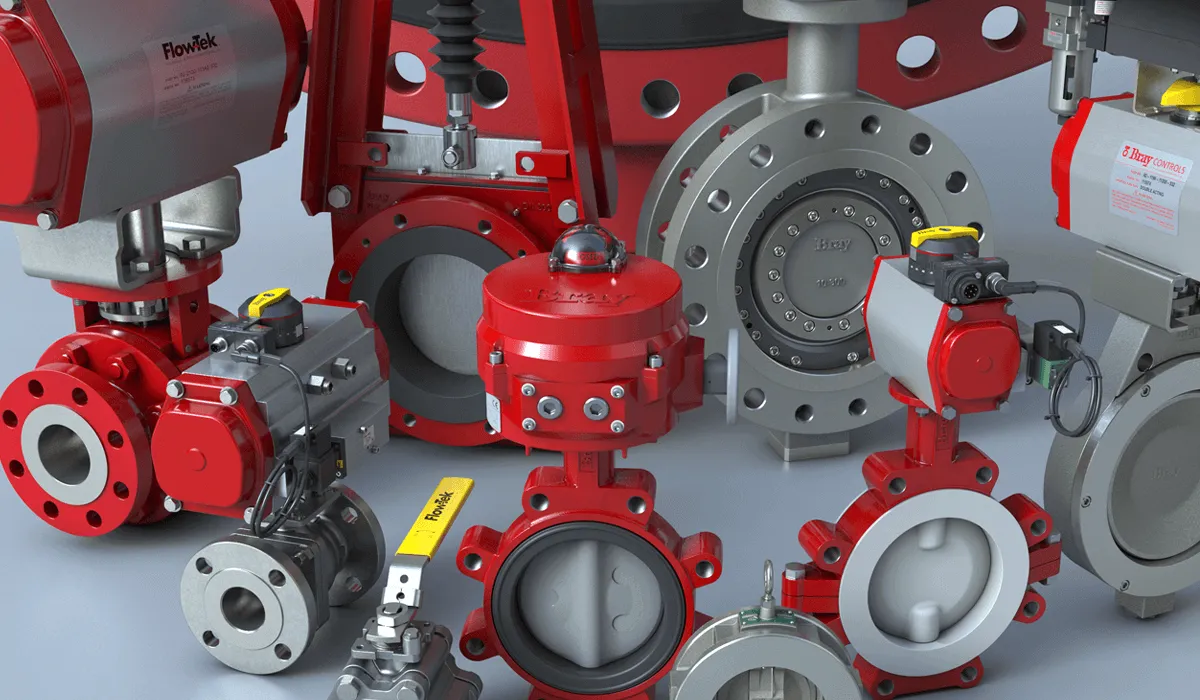

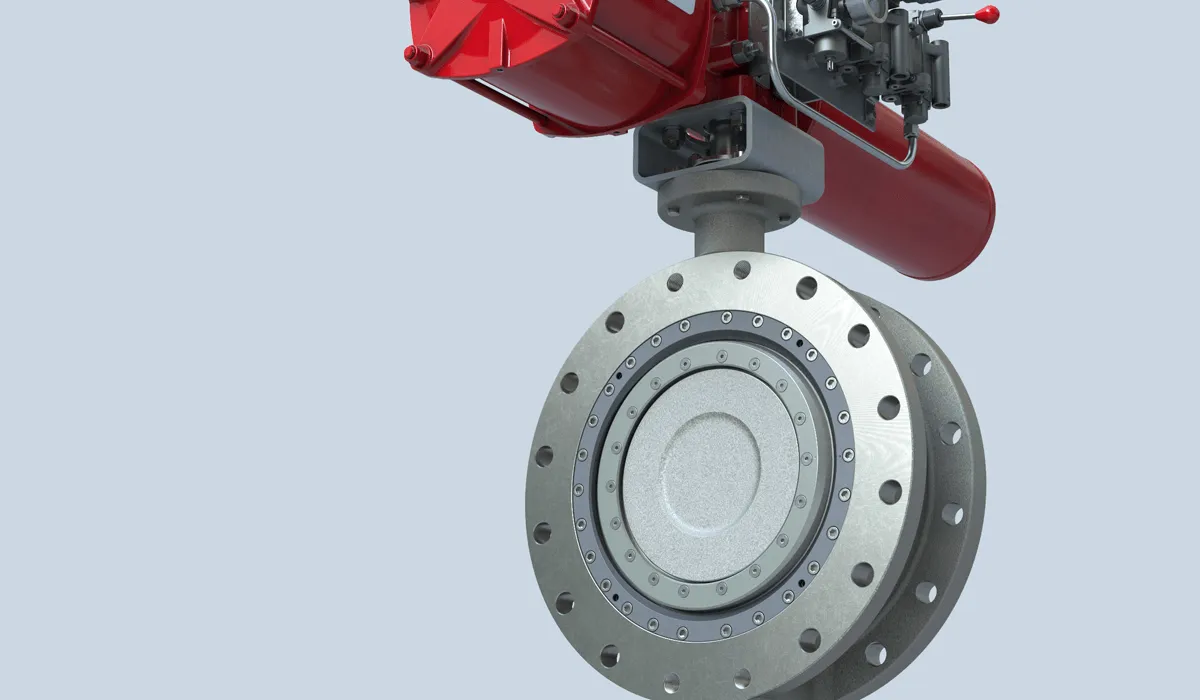

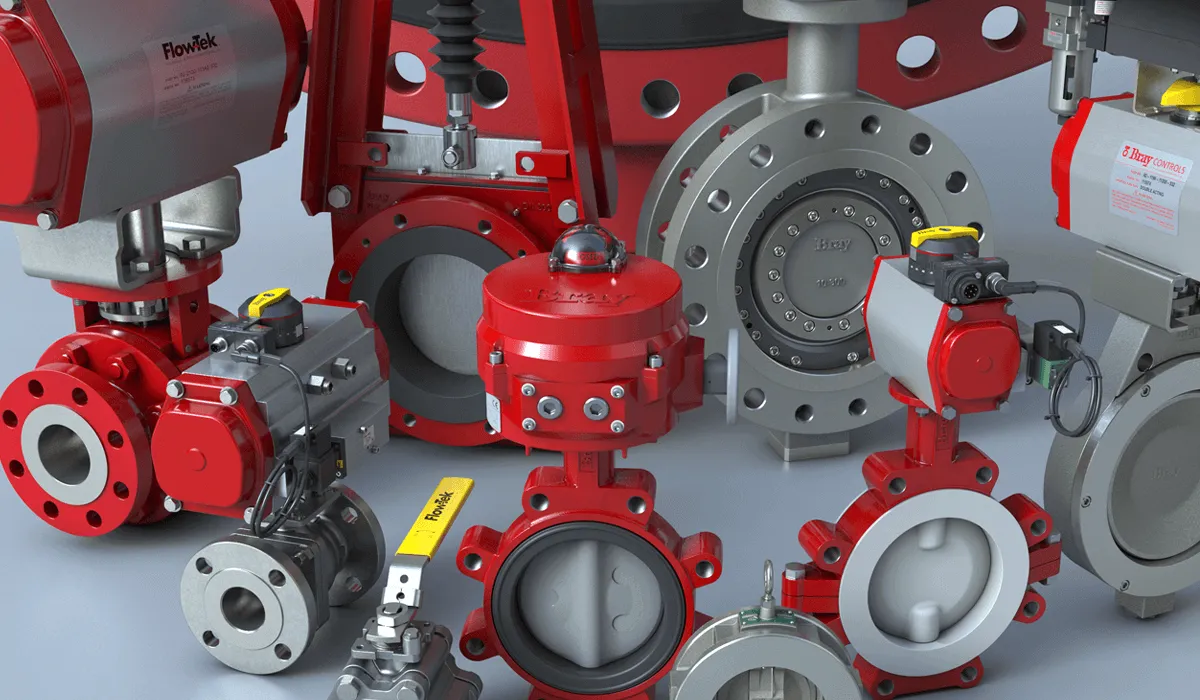

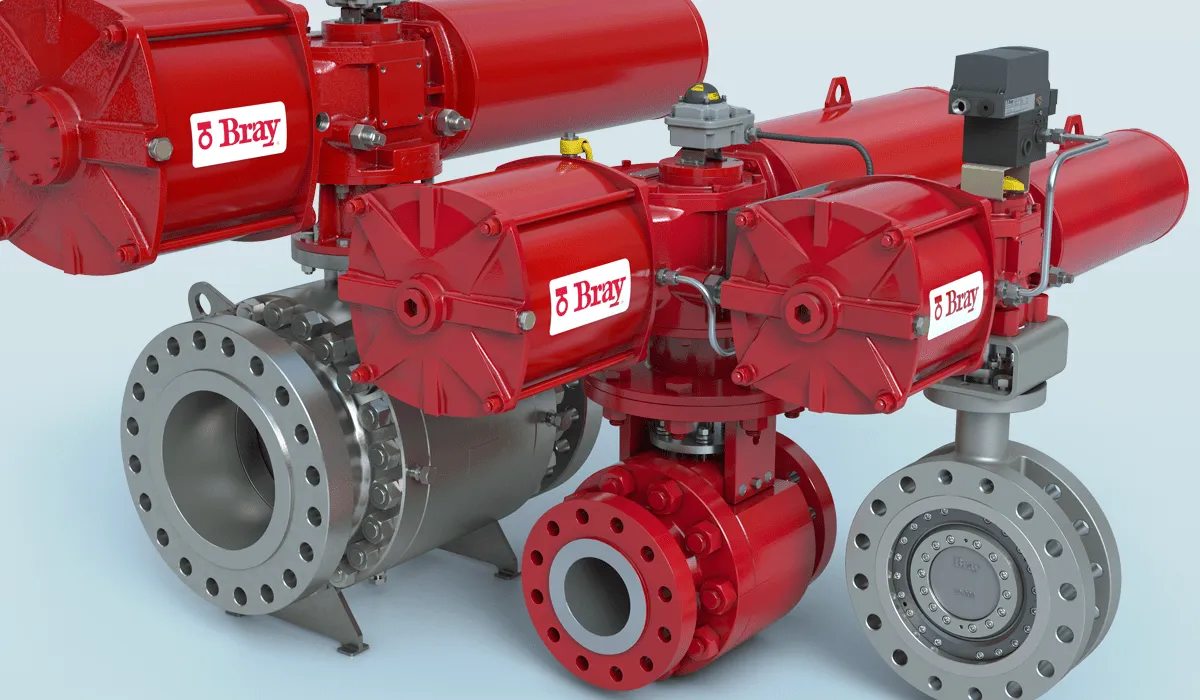

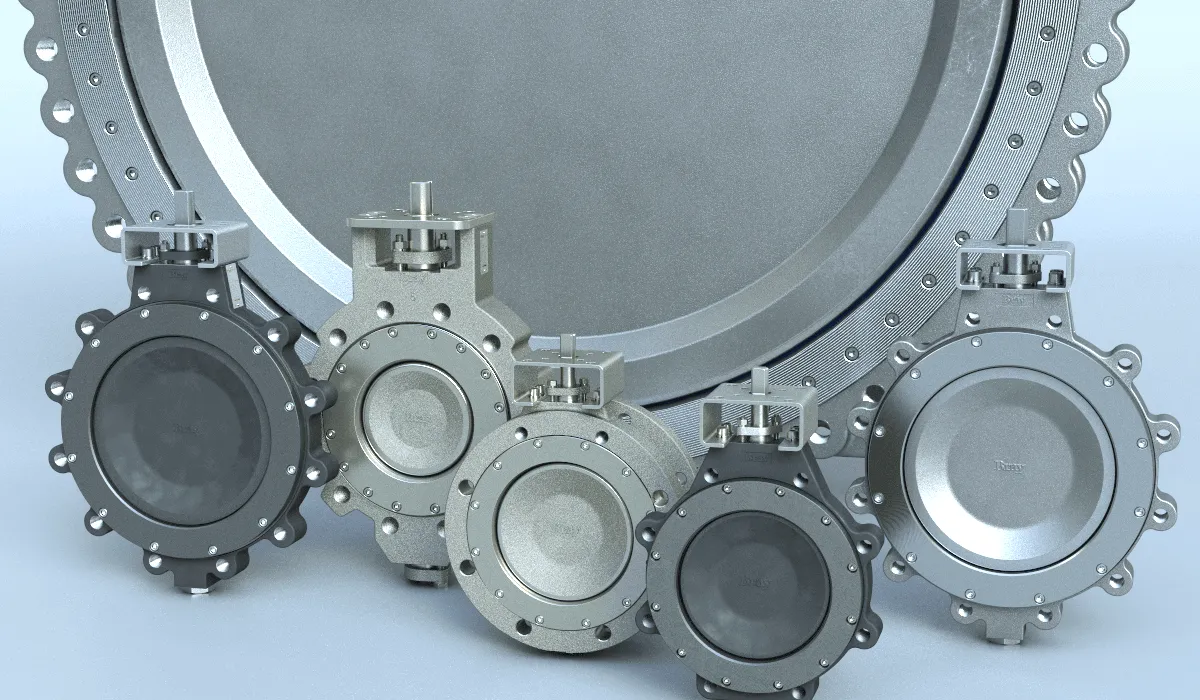

Sugar Cane Industry Solutions

Bray has specifically designed unique and innovative solutions that provide dependable and continuous service in the harshest of sugar & ethanol processes.