Bray's products for

Copper Leaching Plants

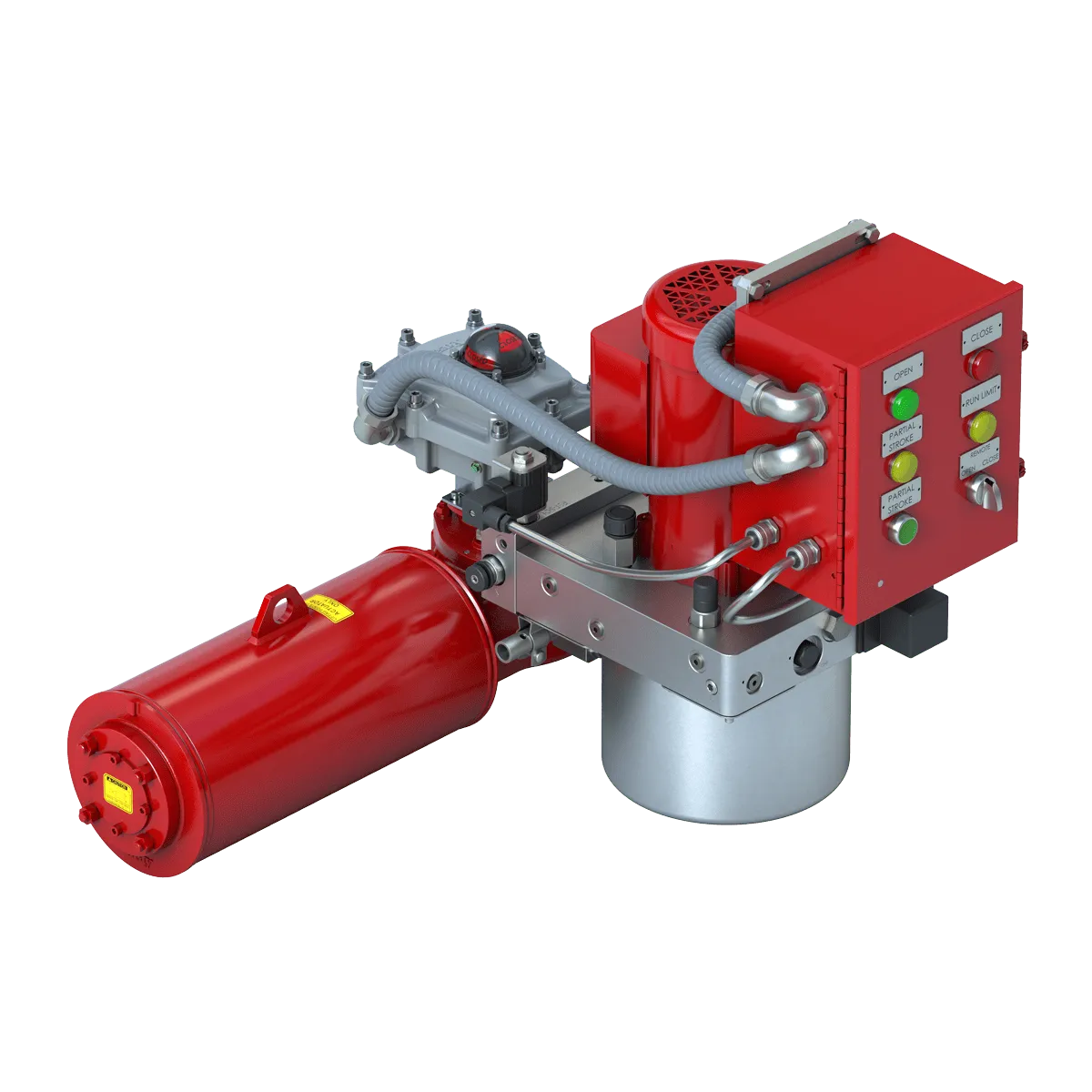

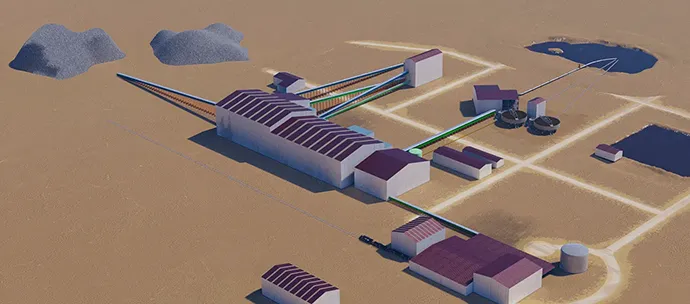

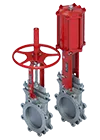

Copper leaching concentrate plants play a crucial role in copper production. Both vat and heap leaching plants utilize acids to leach, collect, and concentrate the valuable copper leached from the ore. Copper extracted by heap leaching is percolated through the pile and collected as pregnant leaching solution, in a concentrates pools for downstream processing. Vat leaching works in a similar way with the solvent holding the copper and the gangue settling to the bottom of the tank. Bray valves, actuators, controls, and accessories can be found in leaching concentrate plants where copper ore is processed by acid leaching.

-

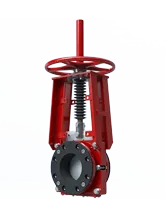

Blending Plant Valves

-

Leach Plant Valves

-

Solvent Extraction Valves

-

Industrial Water Valves

-

Annex Plant Valves

-

Washing Zone Valves

-

Absorption Zone Valves

-

Raffinate Feed Valves

Bray's products for

Copper Electrowinning Plants

Solvent extraction and Electrowinning, also called SX-EW is an electroextraction or electrolysis process for recovering 99.9% pure copper from pregnant leach solution. After the copper is recovered, the solvent solution containing sulfuric acid is recovered and recycled for additional leaching applications. Bray is your trusted partner for valves, actuators, controls and accessories in electrowinning and solvent extraction plants.

Bray's products for

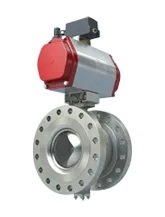

Froth Flotation Concentrator Plants

Flotation separation concentrates production is used with Copper Sulfide bearing ore which is resistant to leaching. Pulverized ore is mixed with water and passed through a series of Hydro cyclones to separate particles by weight. Separated ore is passed to aeration tanks where reagents are added that bind and trap the copper sulfide particles to the reagent. Air injected by valves from the bottom of the tank forms a froth on the top of the tank. The froth, rich in copper, is mechanically skimmed from the tank for downstream processing. Bray offers reliable valves, actuators, controls, and accessories for froth flotation concentrator plant applications including:

-

Flotation Cell Levels Valves

-

Dewatering Valves

-

Valves for Thickeners

-

Valves for Tailings

-

Slurry Transport Valves

-

Filter Plant Valves

-

Hydrocyclone Valves

-

Solvent Extraction Valves

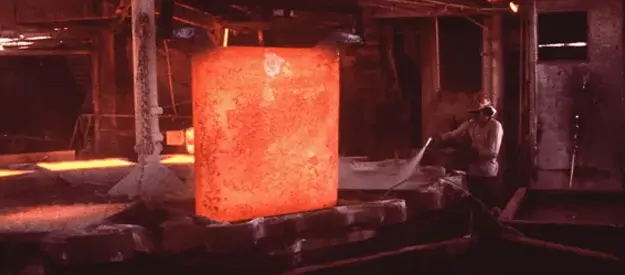

Bray's products for

Copper Smelting

Smelting plants utilize flash furnaces injected with oxygen enriched air to oxidize the copper concentrates and form copper matt. The matt is then processed in a converter furnace where oxygen enriched air is injected to further oxidize the matt, creating copper blister. The blister is transferred to an anode furnace where butane is injected to remove the oxygen from the blister. The 99.5% pure copper blister is formed into anode plates for electrorefining. Bray offers valves actuators and controls for air, oxygen, and butane furnace injection in smelting plants.

-

Air Injection Valves

-

Oxygen Injection Valves

-

Propane Injection Valves

-

Scrubber Valves

Bray's products for

Copper Electrorefining

Copper blister, formed by smelting, is a 99.5% pure. To further refine the copper, electrorefining, a type of electrolysis process is used. The copper anode plates are emersed in an electrolytic solution along with stainless steel cathode plates. DC current is passed through the solution causing the copper to be electrolytically transferred to the stainless-steel cathode plates over a period of 7-10 days forming thick deposits on the stainless steel of 99.99% pure copper. Bray manufactures valves actuators and controls for copper electrorefining plants.

Explore More Bray Insights

Learn Even More About How Bray’s Solutions Can Impact Your Business

.webp?sfvrsn=f84f16e5_1)

-copy.webp?sfvrsn=d2f79d13_1)

.webp)